6Installation

Installerreferenceguide

12

AZQS100~140B8V1B+AZQS100~140B7Y1B

Splitsystemairconditioners

4P3855291–2014.08

Conventionalflaretool

Flaretoolfor

R410A(clutch

type)

Clutchtype

(Ridgidtype)

Wingnuttype

(Imperialtype)

A 0~0.5mm 1.0~1.5mm 1.5~2.0mm

5 Checkthattheflaringisproperlymade.

a Flare’sinnersurfacemustbeflawless.

b Thepipeendmustbeevenlyflaredinaperfectcircle.

c Makesuretheflarenutislifted.

6.4.6 Tobrazethepipeend

The indoor unit and outdoor unit have flare connections. Connect

both ends without brazing. If brazing should be needed, take the

followingintoaccount:

▪ When brazing, blow through with nitrogen to prevent creation of

large quantities of oxidised film on the inside of the piping. This

filmadverselyaffectsvalvesandcompressorsintherefrigerating

systemandpreventsproperoperation.

▪ Setthenitrogenpressureto20kPa(justenoughsoitcanbefelt

ontheskin)withapressurereducingvalve.

a Refrigerantpiping

b Parttobebrazed

c Taping

d Manualvalve

e Pressurereducingvalve

f Nitrogen

▪ DoNOTuseantioxidantswhenbrazingpipejoints.

Residuecanclogpipesandbreakequipment.

▪ Do NOT use flux when brazing coppertocopper refrigerant

piping. Use phosphor copper brazing filler alloy (BCuP), which

doesnotrequireflux.

Flux has an extremely harmful influence on refrigerant piping

systems.Forinstance,ifchlorinebasedfluxisused,itwillcause

pipe corrosion or, in particular, if the flux contains fluorine, it will

deterioratetherefrigerantoil.

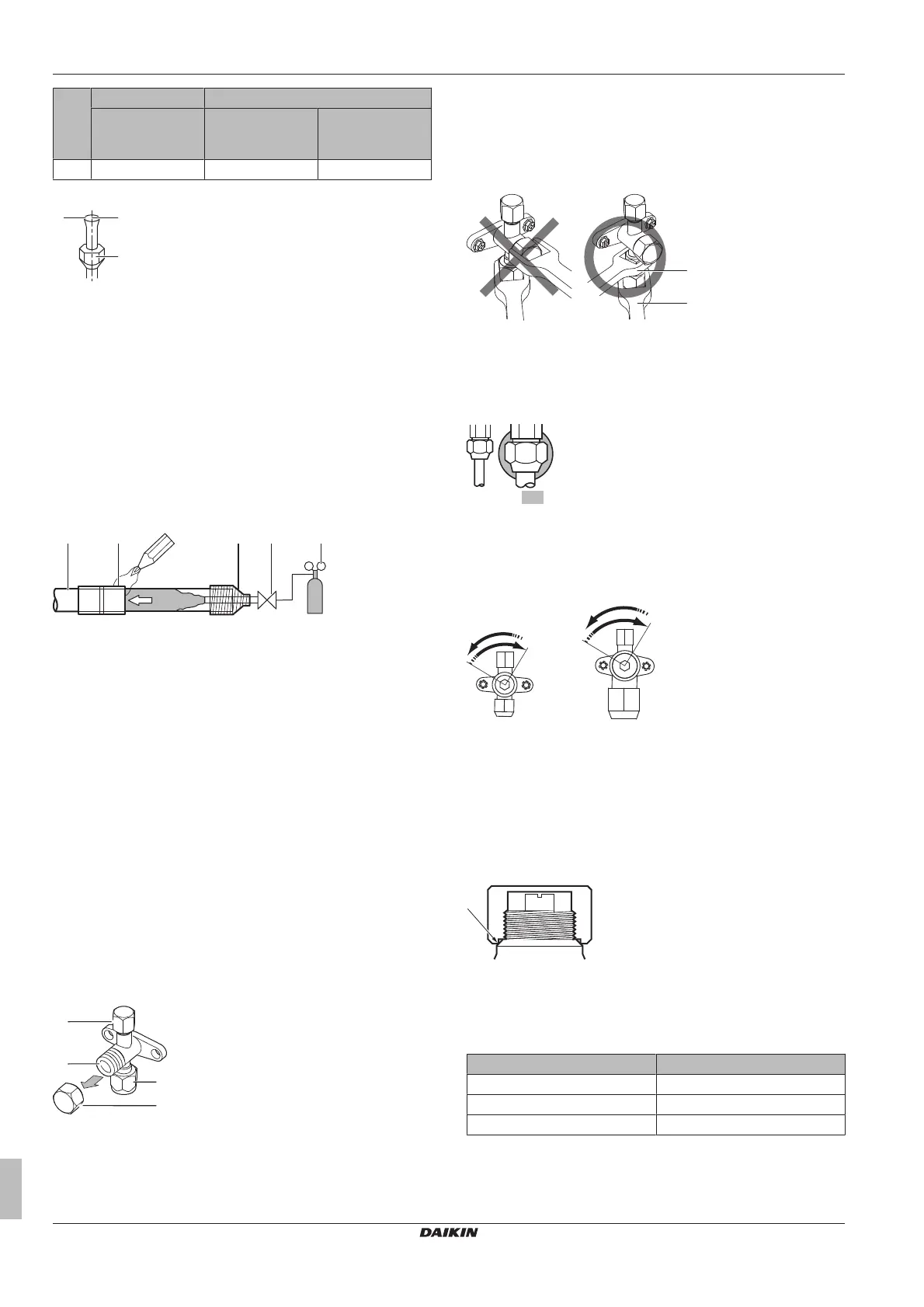

6.4.7 Usingthestopvalveandserviceport

Tohandlethestopvalve

Takethefollowingguidelinesintoaccount:

▪ Thestopvalvesarefactoryclosed.

▪ Thefollowingillustrationshowseachpartrequiredinhandlingthe

valve.

a Serviceportandserviceportcap

b Valvestem

c Fieldpipingconnection

d Stemcap

▪ Keepbothstopvalvesopenduringoperation.

▪ Do NOT apply excessive force to the valve stem. Doing so may

breakthevalvebody.

▪ Alwaysmakesure tosecurethe stopvalvewith a spanner,then

loosenortightentheflarenutwithatorquewrench.DoNOTplace

the spanner on the stem cap, as this could cause a refrigerant

leak.

a Spanner

b Torquewrench

▪ When it is expected that the operating pressure will be low (e.g.

whencooling willbe performedwhiletheoutsideairtemperature

islow),sufficientlysealtheflarenut inthestopvalveonthegas

linewithsiliconsealanttopreventfreezing.

Siliconsealant,makesurethereisnogap.

Toopen/closethestopvalve

1 Removethevalvecover.

2 Insert a hexagon wrench (liquid side: 4 mm, gas side: 6 mm)

intothevalvestemandturnthevalvestem:

Counterclockwisetoopen.

Clockwisetoclose.

3 Whenthevalvestemcannotbeturnedanyfurther,stopturning.

Thevalveisnowopened/closed.

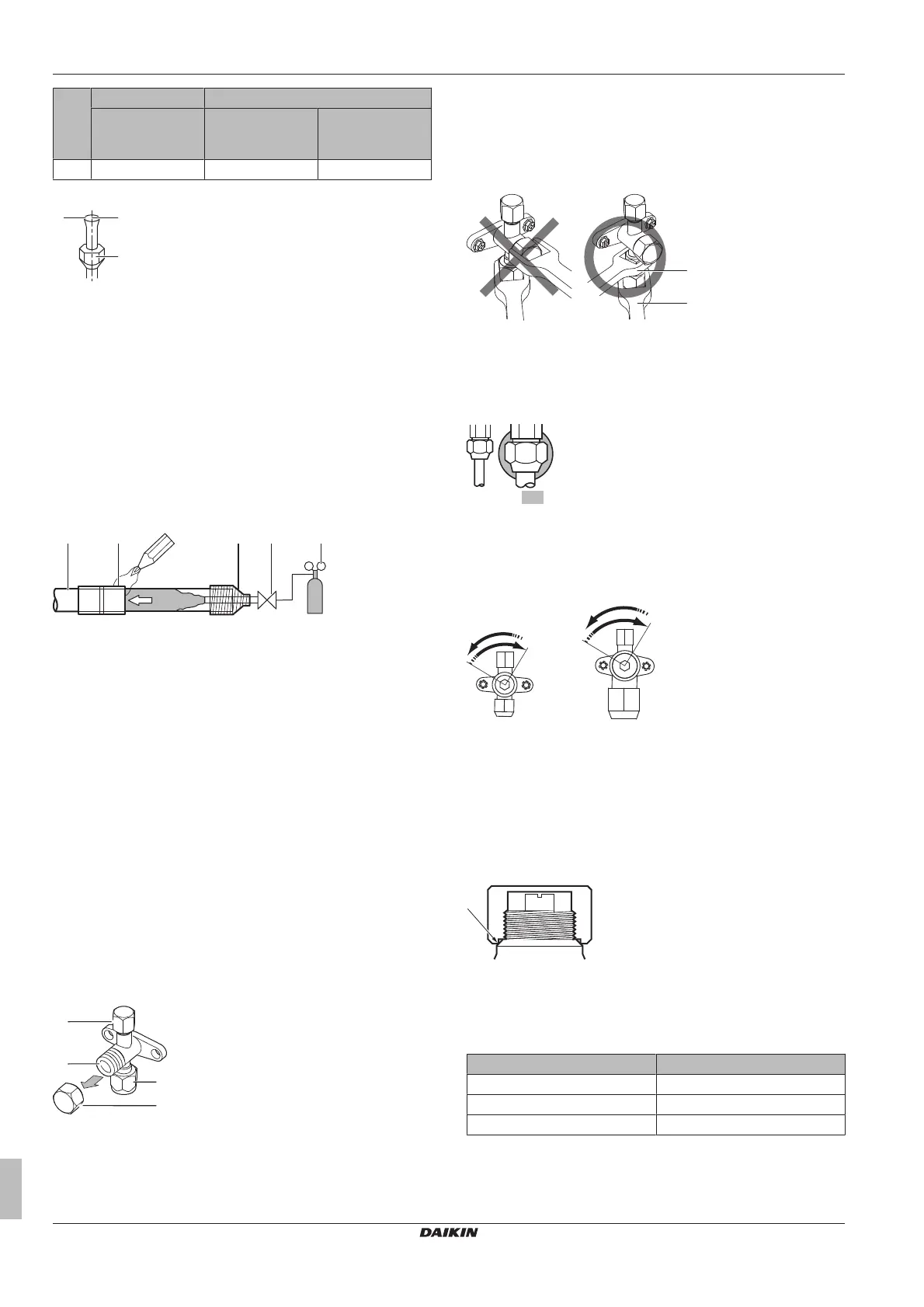

Tohandlethestemcap

Takethefollowingguidelinesintoaccount:

▪ Thestem capissealed whereindicated withthearrow. DoNOT

damageit.

▪ Afterhandling the stopvalve,make suretotighten the stemcap

securely.

▪ Forthetighteningtorque,refertothefollowingtable.

▪ Checkforrefrigerantleaksaftertighteningthestemcap.

Item Tighteningtorque(N∙m)

Stemcap,liquidside 13.5~16.5

Stemcap,gasside 22.5~27.5

Serviceportcap 11.5~13.9

Loading...

Loading...