6Installation

Installerreferenceguide

14

AZQS100~140B8V1B+AZQS100~140B7Y1B

Splitsystemairconditioners

4P3855291–2014.08

6.4.9 Todetermineifoiltrapsarerequired

Ifoilflowsbackintotheoutdoorunit'scompressor,thismightcause

liquidcompressionordeteriorationofoilreturn.Oiltrapsintherising

gaspipingcanpreventthis.

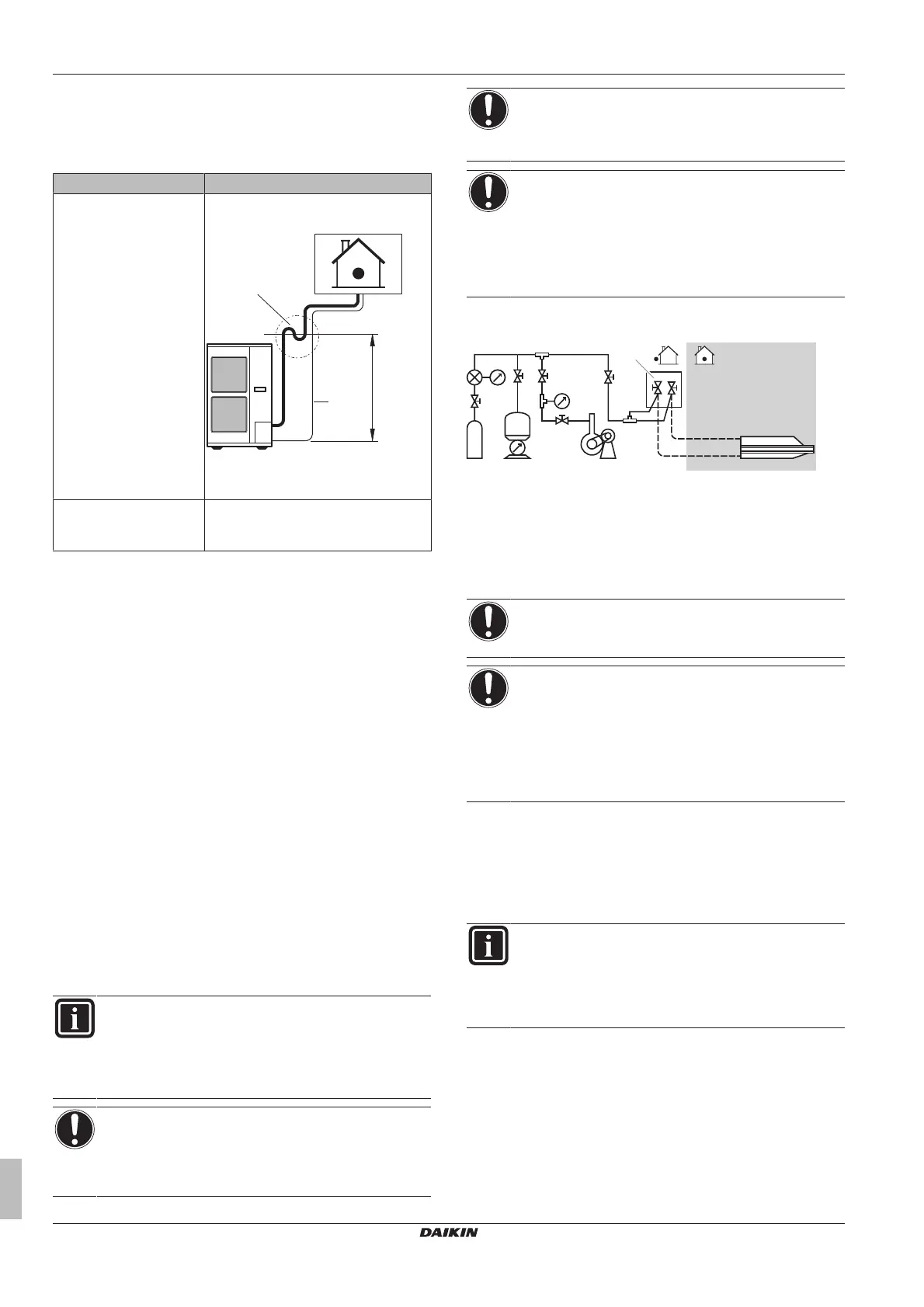

If Then

Theindoorunitisinstalled

higherthantheoutdoor

unit

Installanoiltrapevery10m(height

difference).

aRisinggaspipingwithoiltrap

bLiquidpiping

Theoutdoorunitis

installedhigherthanthe

indoorunit

OiltrapsareNOTrequired.

6.5 Checkingtherefrigerantpiping

6.5.1 Aboutcheckingtherefrigerantpiping

Theoutdoorunit'sinternalrefrigerantpipinghasbeenfactorytested

for leaks. You only have to check the outdoor unit's external

refrigerantpiping.

Beforecheckingtherefrigerantpiping

Makesuretherefrigerantpipingisconnectedbetweentheoutdoor

unitandtheindoorunit.

Typicalworkflow

Checking the refrigerant piping typically consists of the following

stages:

1 Checkingforleaksintherefrigerantpiping.

2 Performing vacuum drying to remove all moisture, air or

nitrogenfromtherefrigerantpiping.

If there is a possibility of moisture being present in the refrigerant

piping (for example, rainwater may have entered the piping), first

carryoutthe vacuumdryingprocedure below untilallmoisture has

beenremoved.

6.5.2 Precautionswhencheckingthe

refrigerantpiping

INFORMATION

Also read the precautions and requirements in the

followingchapters:

▪ Generalsafetyprecautions

▪ Preparation

NOTICE

Use a 2stage vacuum pump with a nonreturn valve that

can evacuate to a gauge pressure of −100.7 kPa (5 Torr

absolute).Makesurethepumpoildoesnotflowoppositely

intothesystemwhilethepumpisnotworking.

NOTICE

Use this vacuum pump for R410A exclusively. Using the

same pump for other refrigerants may damage the pump

andtheunit.

NOTICE

▪ Connectthe vacuumpump toboththeserviceportof

the gas stop valve and the service port of the liquid

stopvalvetoincreaseefficiency.

▪ Makesurethatthegasstopvalveandliquidstopvalve

are firmly closed before performing the leak test or

vacuumdrying.

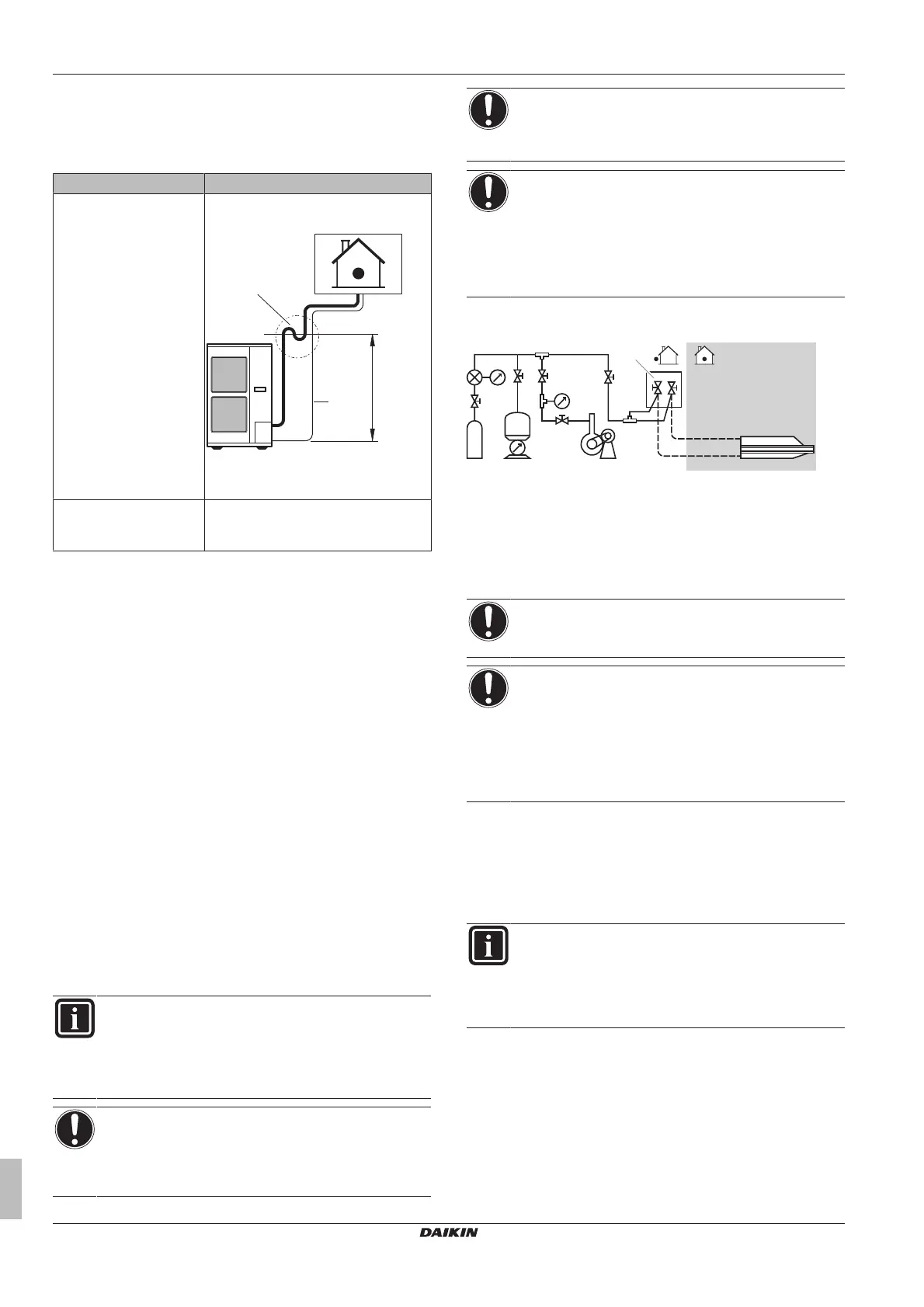

6.5.3 Checkingrefrigerantpiping:Setup

a Pressuregauge

b Nitrogen

c Refrigerant

d Weighingmachine

e Vacuumpump

f Stopvalve

6.5.4 Tocheckforleaks

NOTICE

DoNOTexceedtheunit'smaximumworkingpressure(see

"PSHigh"ontheunitnameplate).

NOTICE

Make sure to use a recommended bubble test solution

from your wholesaler. Do not use soap water, which may

causecrackingofflarenuts(soapwatermaycontainsalt,

which absorbs moisture that will freeze when the piping

gets cold), and/or lead to corrosion of flared joints (soap

water may contain ammonia which causes a corrosive

effectbetweenthebrassflarenutandthecopperflare.

1 Chargethesystemwithnitrogengasuptoagaugepressureof

at least 200 kPa (2 bar). It is recommended to pressurize to

3000kPa(30bar)inordertodetectsmallleaks.

2 Check for leaks by applying the bubble test solution to all

connections.

3 Dischargeallnitrogengas.

INFORMATION

Afteropeningthestopvalve,itispossiblethatthepressure

intherefrigerantpipingdoesNOTincrease.Thismightbe

causedbye.g.the closed state of the expansion valvein

theoutdoorunitcircuit,butdoesNOTpresentanyproblem

forcorrectoperationoftheunit.

Loading...

Loading...