Dakewe (Shenzhen) Medical Equipment Co., Ltd

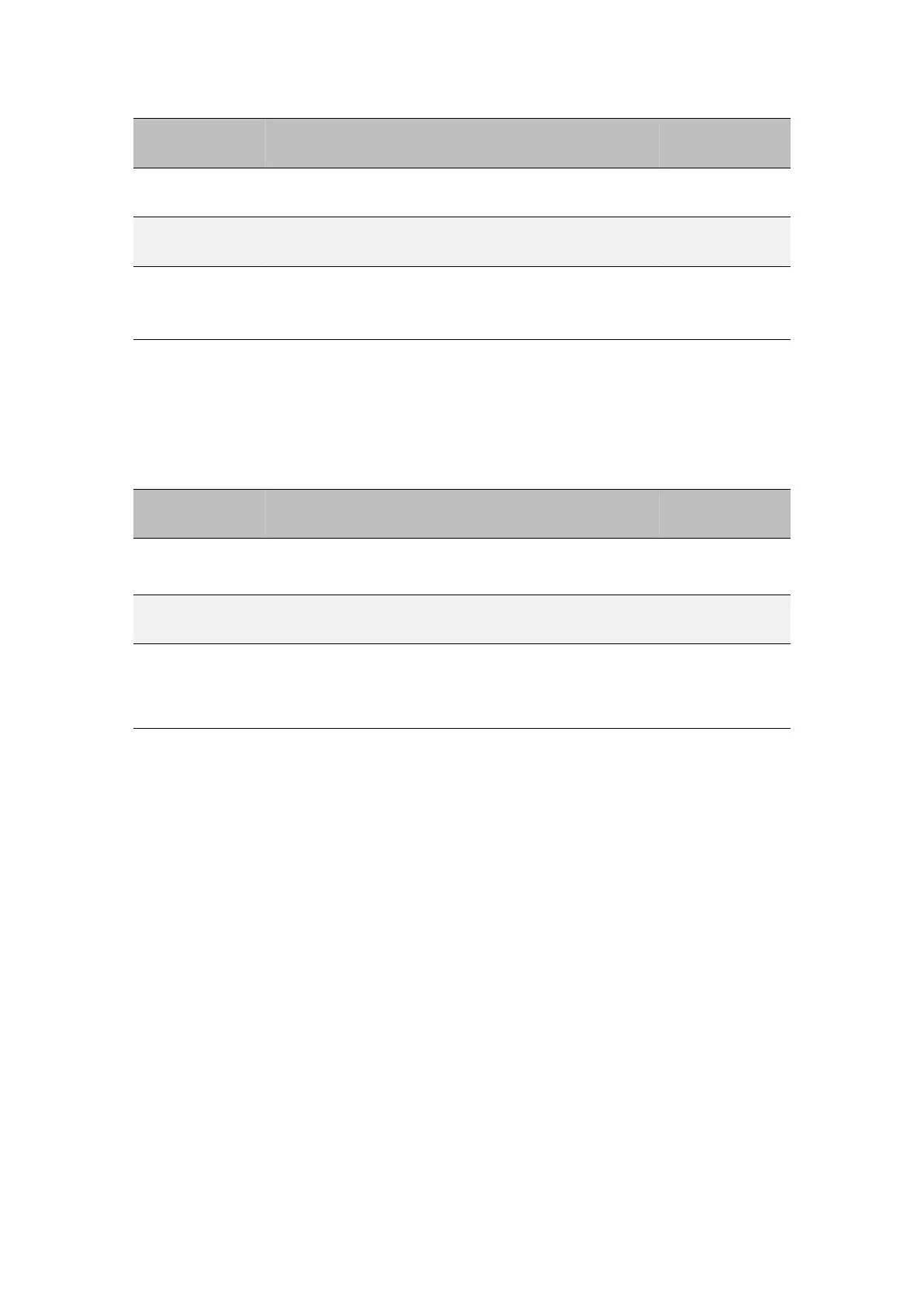

Table 2: Standard Rinse Process (about 1.5h)

Positive and

negative pressure

drying

Vacuum +

positive pressure

Warm rinse: It is used for cleaning the crystals that generate and remain inside the

machine after long-term use, due to the precipitation of paraformaldehyde in the

formalin reagent.

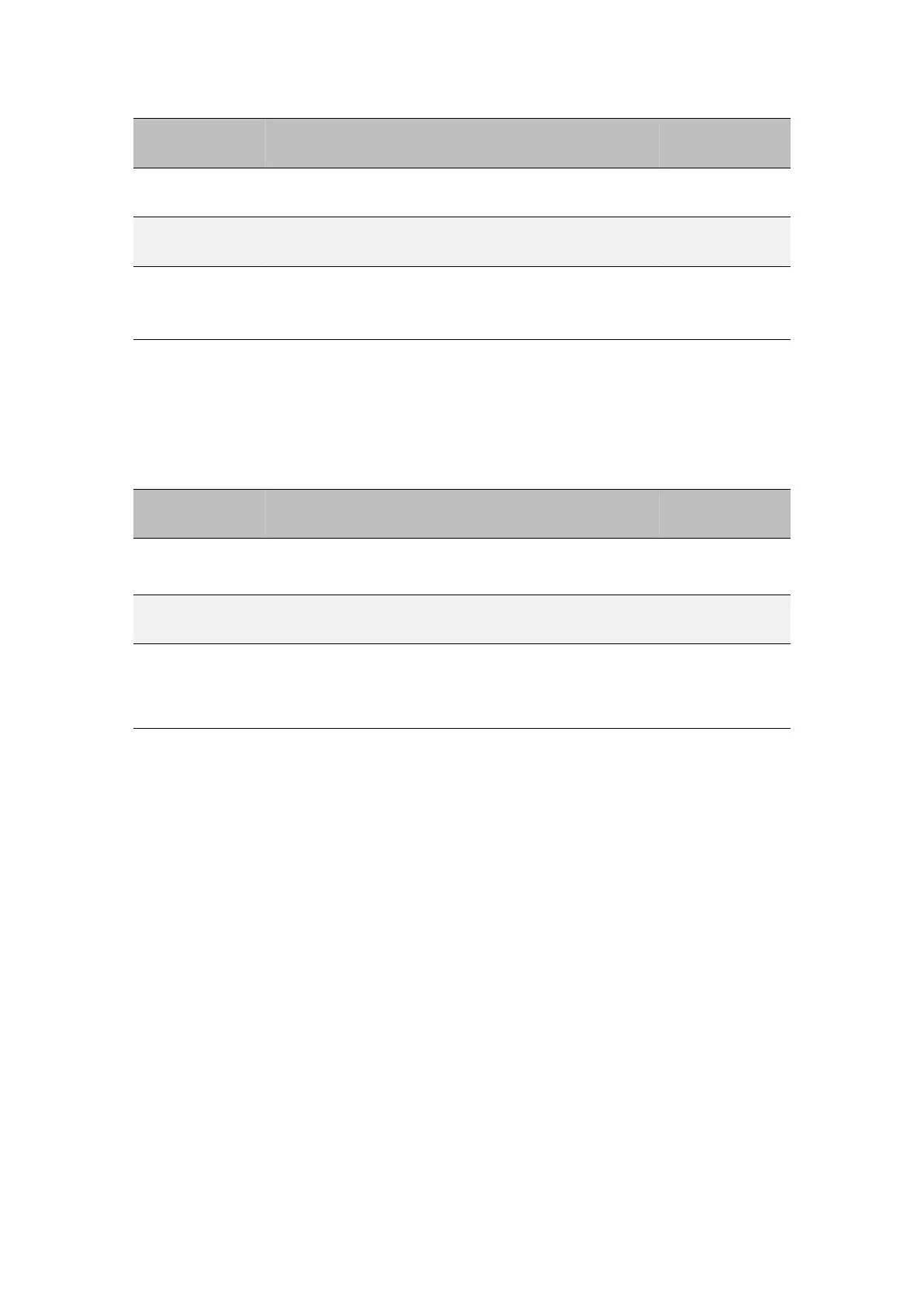

Table 3: Warm Rinse Process (about 1.5h)

Positive and

negative pressure

drying

Vacuum +

positive pressure

9.1.1 Rinse Process Step Operation

1. Before running rinse, confirm that all tissue samples inside the dehydration

cylinder have been removed;

2. Confirm that the cylinder lid has been locked;

3. Select the type of the rinse process. Click the process button. The system

begins to activate the rinse process. The process running steps are displayed

in an animated form on the interface;

9.1.2 Rinse Process Precautions

If reagent quality control is enabled in the system, the system will record the number of

times the cleaning reagent is used, and prompt the status of the cleaning reagent

according to the number of times used.

When the use times of the cleaning reagent has reached the system default maximum

use times, the interface will prompt the reagent expiration information and prompt

Loading...

Loading...