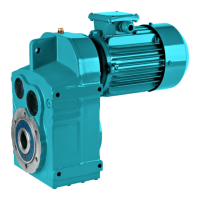

How to troubleshoot a DANA Engine gearbox that does not start?

- RRyan GillespieAug 13, 2025

If your DANA Engine gearbox is not starting, verify that the voltage supply and frequency of your electrical connection match the motor's nameplate. Refer to the motor manufacturer's start-up manual. If the problem persists, the load might be too high for the motor. Detach the gearbox from the load/torque. If it starts working, the starting torque is insufficient, and a higher motor power is needed. For single-phase motors, also inspect the starting and running capacitors. If none of these steps resolve the issue, proceed to ID 100.