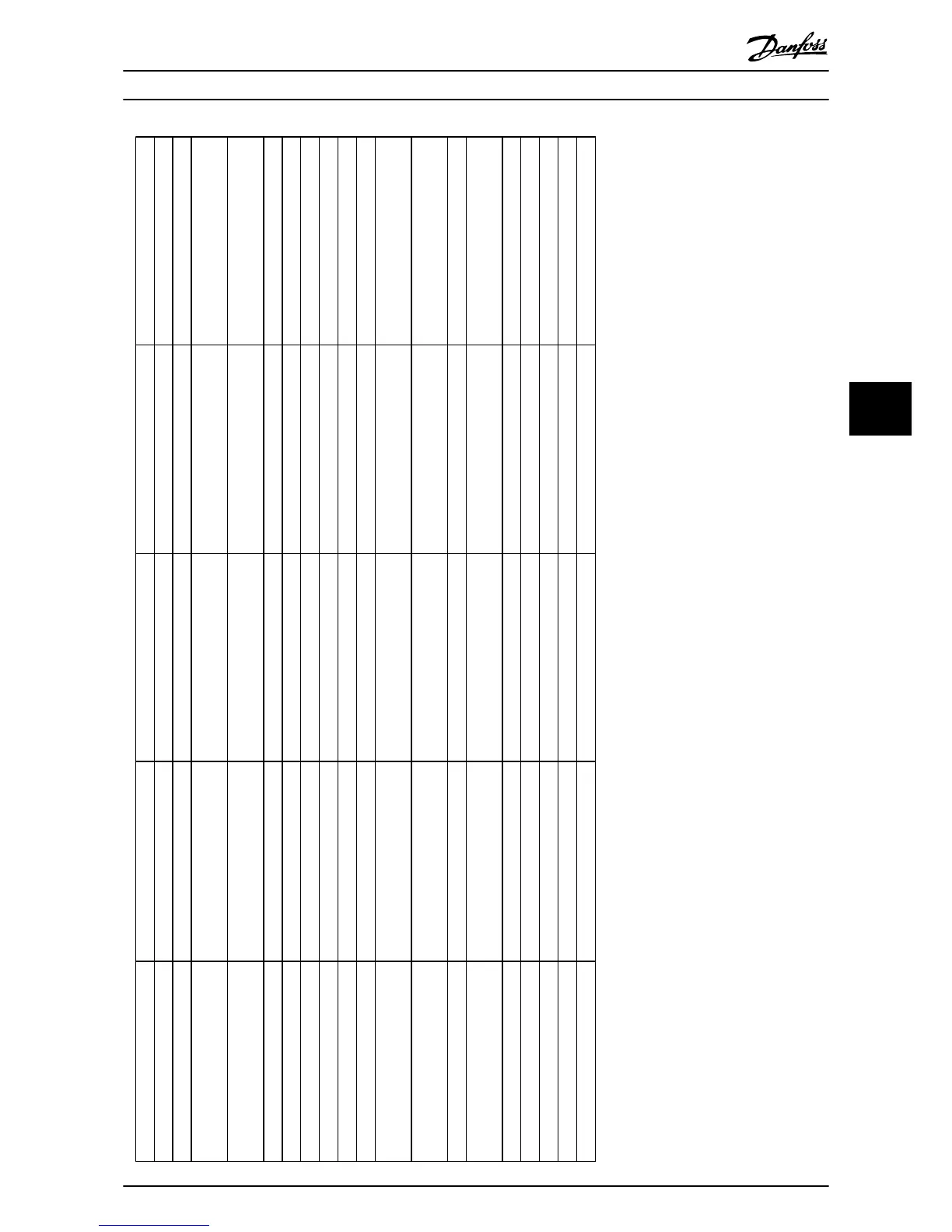

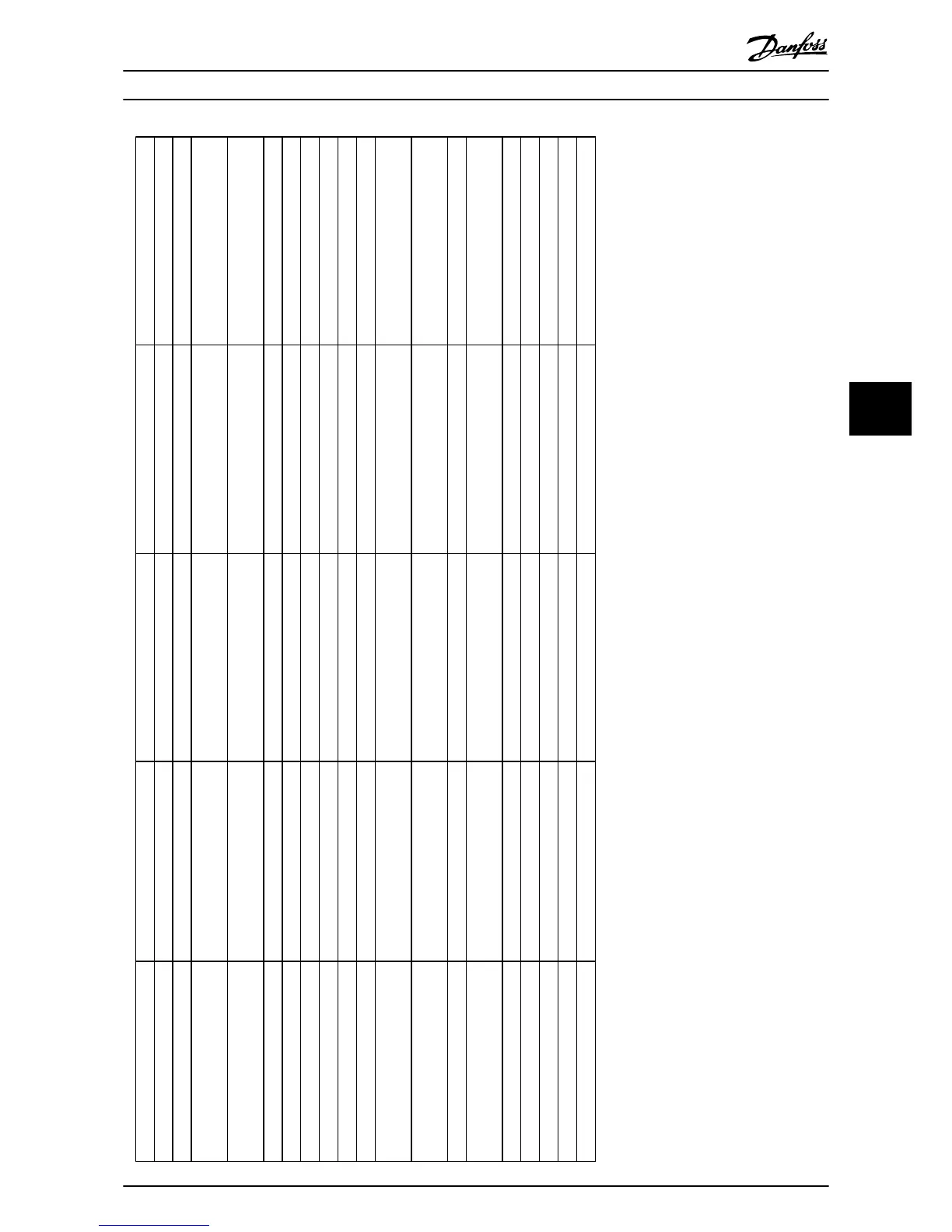

6-11 Terminal 53 High Voltage 20-21 Setpoint 1 22-22 Low Speed Detection 22-21 Low Power Detection 22-87 Pressure at No-Flow Speed

6-12 Terminal 53 Low Current 20-22 Setpoint 2 22-23 No-Flow Function 22-22 Low Speed Detection 22-88 Pressure at Rated Speed

6-13 Terminal 53 High Current 20-81 PID Normal/ Inverse Control

22-24 No-Flow Delay

22-23 No-Flow Function 22-89 Flow at Design Point

6-14 Terminal 53 Low Ref./Feedb.

Value

20-82 PID Start Speed [RPM] 22-40 Minimum Run Time 22-24 No-Flow Delay 22-90 Flow at Rated Speed

6-15 Terminal 53 High Ref./Feedb.

Value

20-83 PID Start Speed [Hz] 22-41 Minimum Sleep Time 22-40 Minimum Run Time 1-03 Torque Characteristics

6-16 Terminal 53 Filter Time Constant 20-93 PID Proportional Gain 22-42 Wake-up Speed [RPM] 22-41 Minimum Sleep Time 1-73 Flying Start

6-17 Terminal 53 Live Zero 20-94 PID Integral Time 22-43 Wake-up Speed [Hz] 22-42 Wake-up Speed [RPM] Q3-42 Compressor Functions

6-20 Terminal 54 Low Voltage 20-70 Closed Loop Type 22-44 Wake-up Ref./FB Difference 22-43 Wake-up Speed [Hz] 1-03 Torque Characteristics

6-21 Terminal 54 High Voltage 20-71 PID Performance 22-45 Setpoint Boost 22-44 Wake-up Ref./FB Difference 1-71 Start Delay

6-22 Terminal 54 Low Current 20-72 PID Output Change 22-46 Maximum Boost Time 22-45 Setpoint Boost 22-75 Short Cycle Protection

6-23 Terminal 54 High Current 20-73 Minimum Feedback Level 2-10 Brake Function 22-46 Maximum Boost Time 22-76 Interval between Starts

6-24 Terminal 54 Low Ref./Feedb.

Value

20-74 Maximum Feedback Level 2-16 AC brake Max. Current 22-26 Dry Pump Function 22-77 Minimum Run Time

6-25 Terminal 54 High Ref./Feedb.

Value

20-79 PID Autotuning 2-17 Over-voltage Control 22-27 Dry Pump Delay 5-01 Terminal 27 Mode

6-26 Terminal 54 Filter Time Constant

Q3-4 Application Settings

1-73 Flying Start 22-80 Flow Compensation 5-02 Terminal 29 Mode

6-27 Terminal 54 Live Zero Q3-40 Fan Functions 1-71 Start Delay 22-81 Square-linear Curve Approxi-

mation

5-12 Terminal 27 Digital Input

6-00 Live Zero Timeout Time 22-60 Broken Belt Function 1-80 Function at Stop 22-82 Work Point Calculation 5-13 Terminal 29 Digital Input

6-01 Live Zero Timeout Function 22-61 Broken Belt Torque 2-00 DC Hold/Preheat Current 22-83 Speed at No-Flow [RPM] 5-40 Function Relay

4-56 Warning Feedback Low 22-62 Broken Belt Delay 4-10 Motor Speed Direction 22-84 Speed at No-Flow [Hz] 1-73 Flying Start

4-57 Warning Feedback High 4-64 Semi-Auto Bypass Set-up Q3-41 Pump Functions 22-85 Speed at Design Point [RPM] 1-86 Trip Speed Low [RPM]

20-20 Feedback Function 1-03 Torque Characteristics 22-20 Low Power Auto Set-up 22-86 Speed at Design Point [Hz] 1-87 Trip Speed Low [Hz]

Table 5.3 Quick Menu Structure

About Frequency Converter P...

VLT

®

HVAC Drive Operating Instructions

MG11AI02 - VLT

®

is a registered Danfoss trademark

41

5 5

Loading...

Loading...