GENERAL INFORMATIONPRODUCT INFORMATIONINTEGRATION INTO SYSTEMORDERING INFORMATION SYSTEM DESIGN

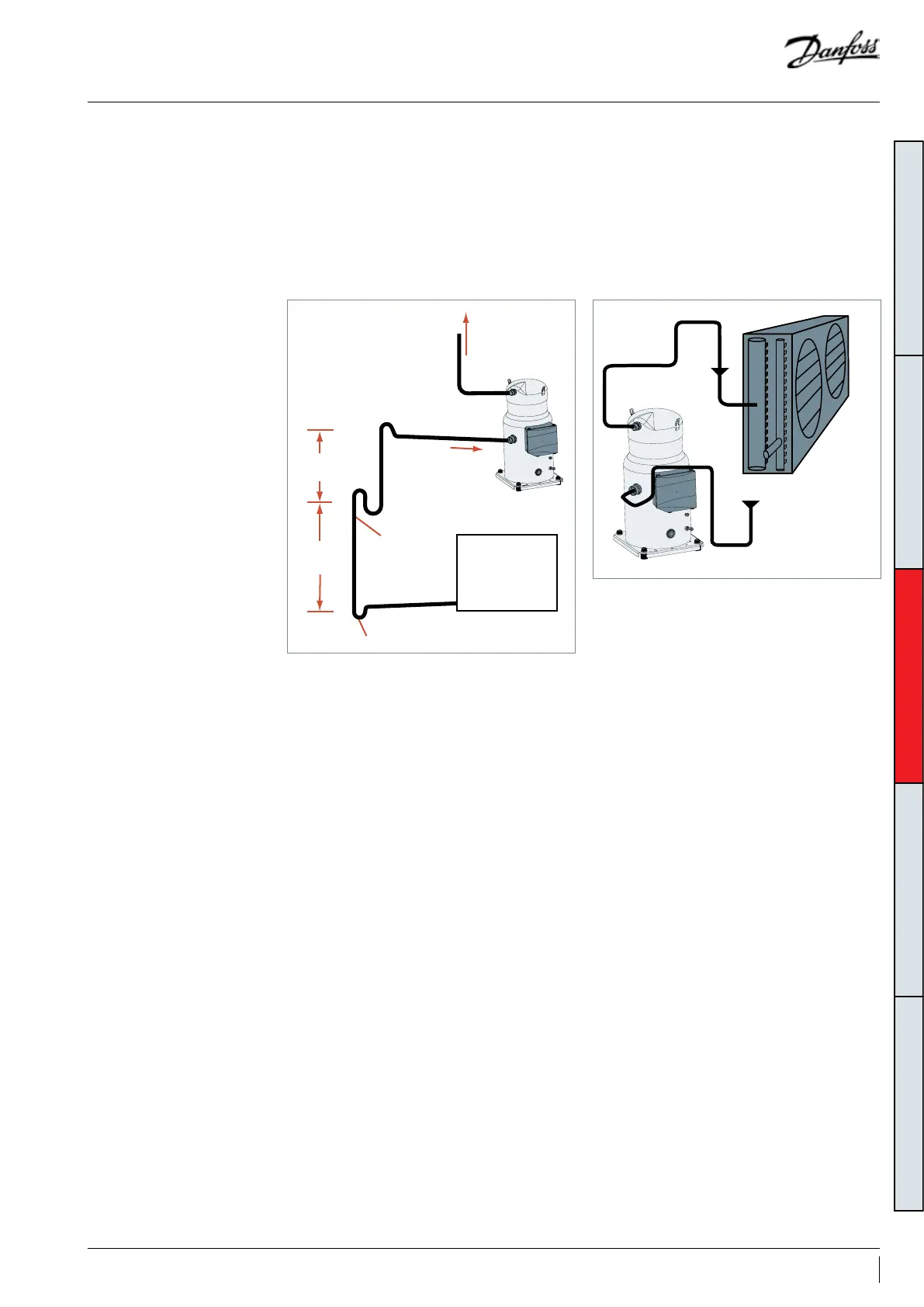

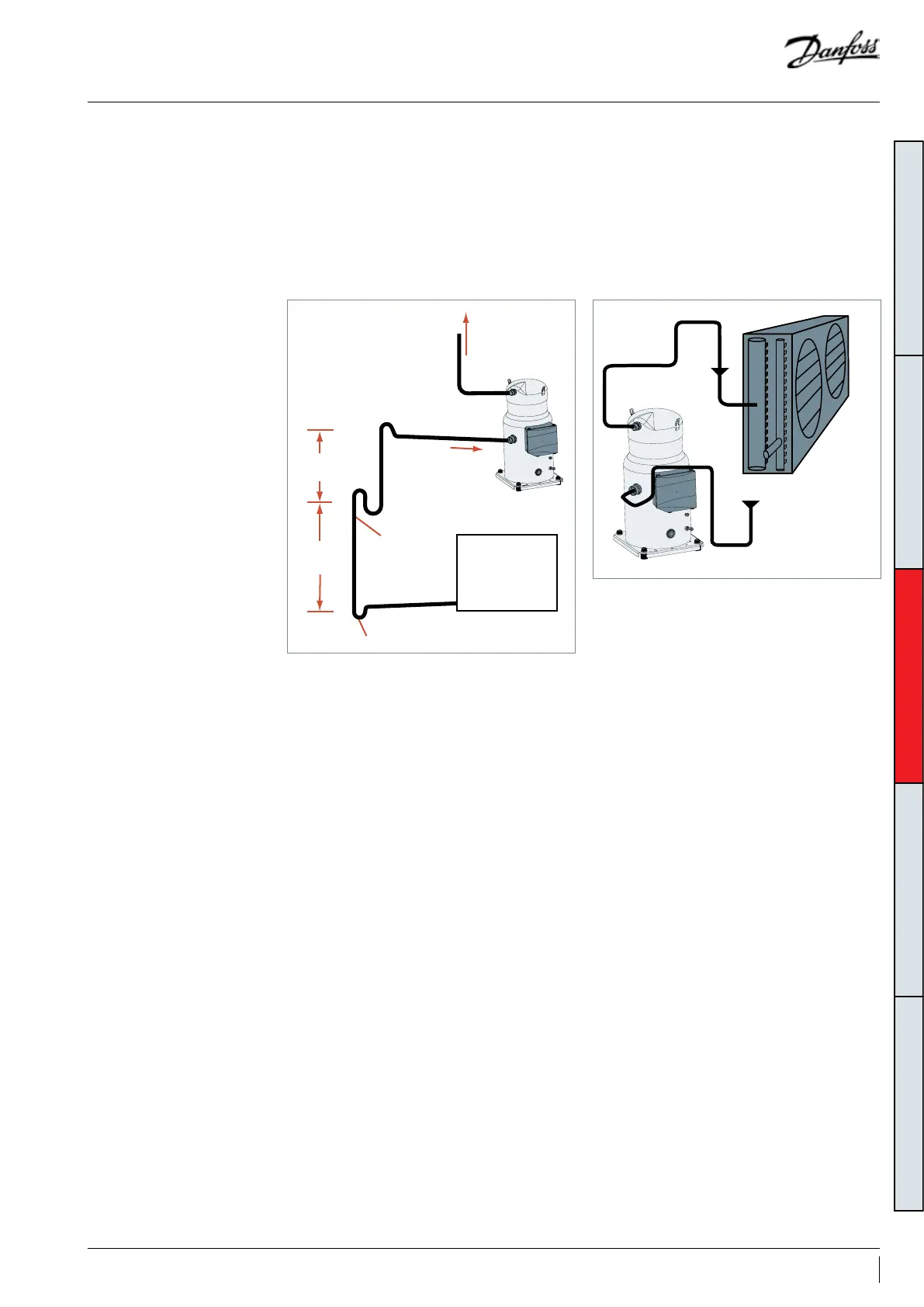

Design piping

General requirements Proper piping practices should be employed to:

1. Ensure adequate oil return, even under

minimum load conditions (refrigerant speed,

piping slopes…). For validation tests see section

“Manage oil in the circuit”.

2. Avoid condensed liquid refrigerant from

draining back to the compressor when stopped

(discharge piping upper loop). For validation

tests see section “Manage off cycle migration”.

General recommendations are described in the

figures below:

3. Piping should be designed with adequate

three-dimensional flexibility to avoid excess

vibration. It should not be in contact with the

surrounding structure, unless a proper tubing

mount has been installed. For more information

on noise and vibration, see section on: “Sound

and vibration management”.

HP

4m/s (13 ft/s)

or more

0.5% slope

To condenser

max. 4m

(13ft)

max. 4m

(13ft)

0.5% slope

U-trap, as short as possible

4m/s (13ft/s)

or more

U trap, as short as possible

Evaporator

LP

8 to 12m/s

(26 to 40ft/s)

HP

LP

Condenser

3D exibility

Upper loop

21FRCC.PC.045.A7.02

Loading...

Loading...