© Danfoss | August 2018 AQ00000211 | 173

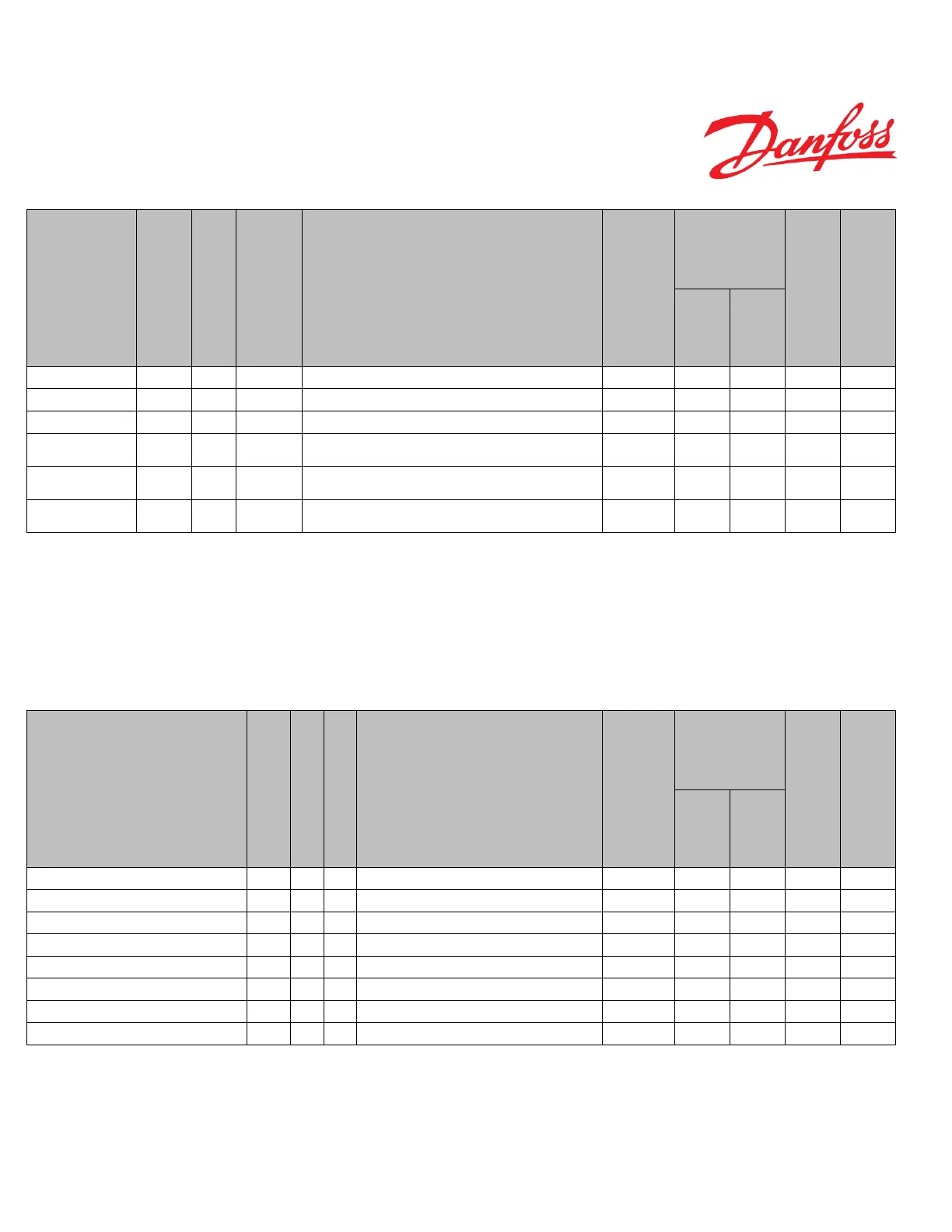

Name

Description of parameter

Range

Safety critical

parameters ‘S’

WAS max left position

(CAN)

P3185 U16 mVolts Wheel angle sensor voltage output for leftmost position over CAN OEM, Dealer 0 5000 500

WAS max right position

(CAN)

P3187 U16 mVolts Wheel angle sensor voltage output for rightmost position over CAN OEM, Dealer 0 5000 4500

WAS neutral position

(CAN)

P3189 U16 mVolts Wheel angle sensor voltage output for neutral position over CAN OEM, Dealer 0 5000 2500

cylinder stroke volume

P3191 U16 ccm

Automatic adjusted cylinder stroke volume, for using CAN WAS, found

during WAS auto-calibration

100 65535 65535

maximum steer angle to

P3193 U16 Deg

Automatic adjusted maximum steer angle to left side, for using CAN WAS,

found during WAS auto-calibration

0 65535 65535

maximum steer angle to

P3195 U16 Deg

Automatic adjusted maximum steer angle to right side, for using CAN

WAS, found during WAS auto-calibration

0 65535 65535

Table 84

• Calculate the sector CRC as CRC-16-CCITT(P3185…P3196) and store (word) at the CRC/Checksum address

(P3203). For example of how to calculate sector CRC, please see paragraph 17.5.2.

• Furthermore, populate a temporary data sector for “Production/Calibration Flag”. Update the CAN based WAS

calibration counters. Increment P3775 from 0 to 1 and increment bit-wise inverted P3776 from 255 to 254 for the

displayed below,

Production/Calibration Flag

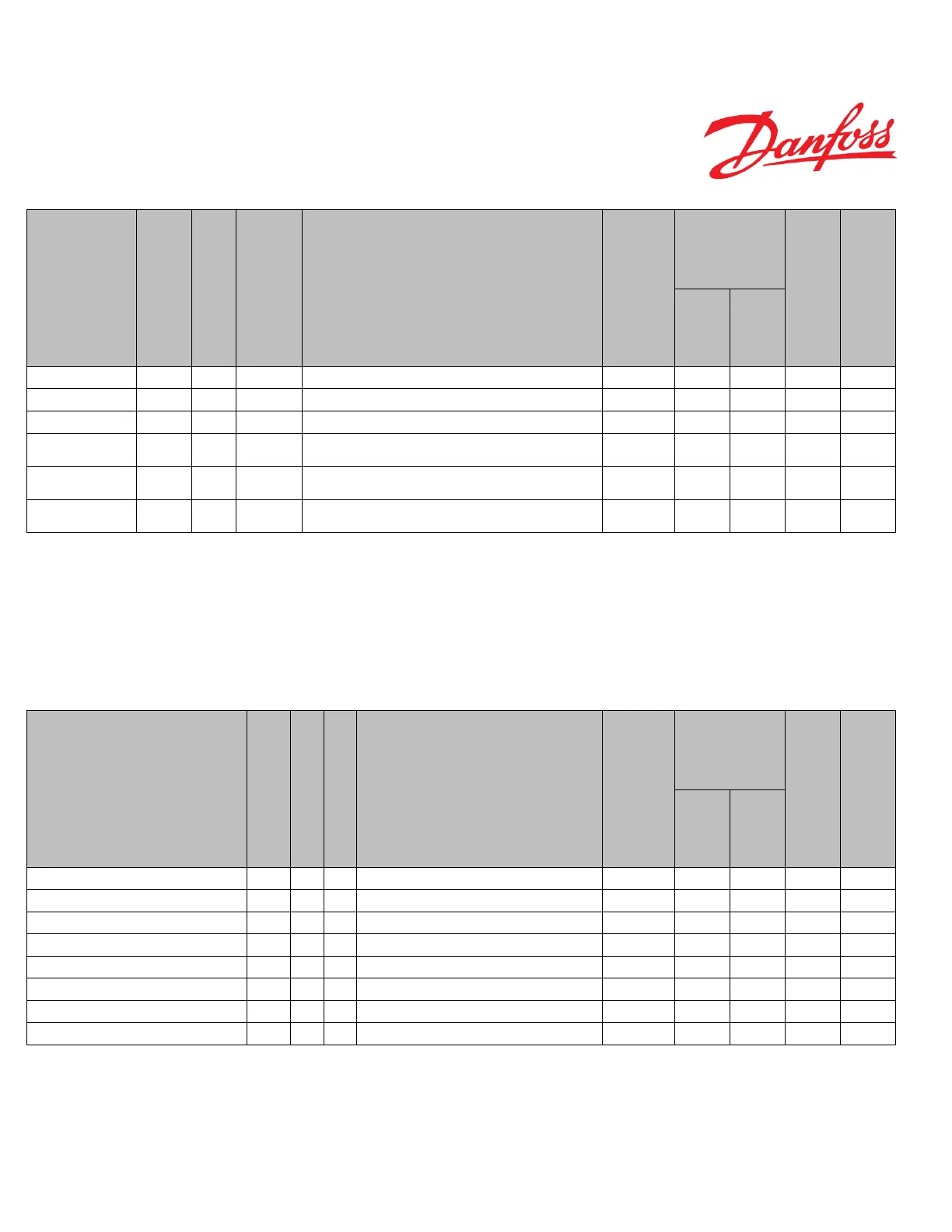

Name

Description of parameter

Range

Safety critical

parameters ‘S’

Calibration counter - Spool calibration

P3771 U8 - Calibration counter - Spool calibration OEM 0 255 0

Bit inverted value for "Calibration counter - Spool

calibration"

P3772 U8 -

Bit inverted value for "Calibration counter - Spool

calibration"

OEM 0 255 255

Calibration counter - Analogue WAS calibration

P3773 U8 - Calibration counter - Analogue WAS OEM 0 255 0

Bit inverted value for "Calibration counter - Analogue

WAS calibration"

P3774 U8 -

Bit inverted value for "Calibration counter - Analogue

WAS"

OEM 0 255 255

Calibration counter - CAN WAS calibration

P3775 U8 - Calibration counter - CAN WAS OEM 0 255 0

Bit inverted value for "Calibration counter - CAN

WAS calibration"

P3776 U8 - Bit inverted value for "Calibration counter - CAN WAS" OEM 0 255 255

Calibration counter - Analogue joystick P3777 U8 - Analogue sensor based Joystick calibration counter OEM 0 255 0

Bit inverted value for "Calibration counter - Analogue

joystick"

P3778 U8 -

Bit inverted value for Analogue sensor based Joystick

calibration counter

OEM 0 255 255

Table 85

• Calculate the sector CRC as CRC-16-CCITT (P3771…P3778) and store (word) at the CRC/Checksum address

(P3789). For example of how to calculate sector CRC, please see paragraph 17.5.2

Loading...

Loading...