68 | © Danfoss | August 2018 AQ00000211

Maximum and minimum closed loop dead-band value (for both left and right-side), hence the found dead-band values

needs to be in between P3799 and P3797.

• Right: P3799 ≤ “test_db_R” ≤ P3797; knowing that “test_db_R” will be found during the spool calibration and

be equal to P3168.

• Left: -P3797 ≤ “test_db_L” ≤ -P3799; knowing that “test_db_L” will be found during the spool calibration and

be equal to P3166.

Important

These parameters control the risk of effectuating non plausible large closed-loop dead-band values.

P3801:

Before automatic spool calibration can be started, the steering wheel has to be armed first. This is to tell the PVED-CLS,

that grabbing the steering wheel can be detected, and thus can be used to disengage ongoing spool calibration.

In the operation status message, byte 4 (see PVED-CLS communication protocol, chapter 7.10), the Spool calibration

status can be observed.

• 0x21: Spool calibration inactive – Steering wheel has not been armed yet.

• 0x22: Spool calibration getting armed – the steering is being operated to “STW_ON” (see 3.6)

• 0x23: Spool calibration armed – steering wheel is not being operated or steering wheel operation is stopped and

a counter has started. Now the “Start calibration”-button has to be pushed in the PLUS+1 Service Tool or send

the message “Spool Calibration Start request” (see PVED-CLS communication protocol, chapter 5.1.1) within

the counter has reached the threshold limit given by P3801 (in seconds)

P3802:

The initial spool position value, at which the spool auto-calibration function will start from. The higher the set-point, the

faster the wheels movement will be.

Danfoss recommends setting P3802 set to 115 for OSPE/EHi valve and 200 for EHPS.

Important

It needs to be assured that this value is in the flow range (see Figure )

P3804:

This is the +/- turn range sweep where the auto-calibration function will measure the time for when moving the spool from

left to right and right to left. P3804 is given in [dDeg], hence 1 = 0,1°. E.g. if P3804 is set to 1°, time will be measured

across +/- 1° = 2° in total.

P3806, P3808:

P3806 and P3808 indicate the target sweep time for the spool calibration function, to find an acceptable closed loop dead-

band edge. That maximum given time is defined by P3806. The minimum given time is defined by P3808.

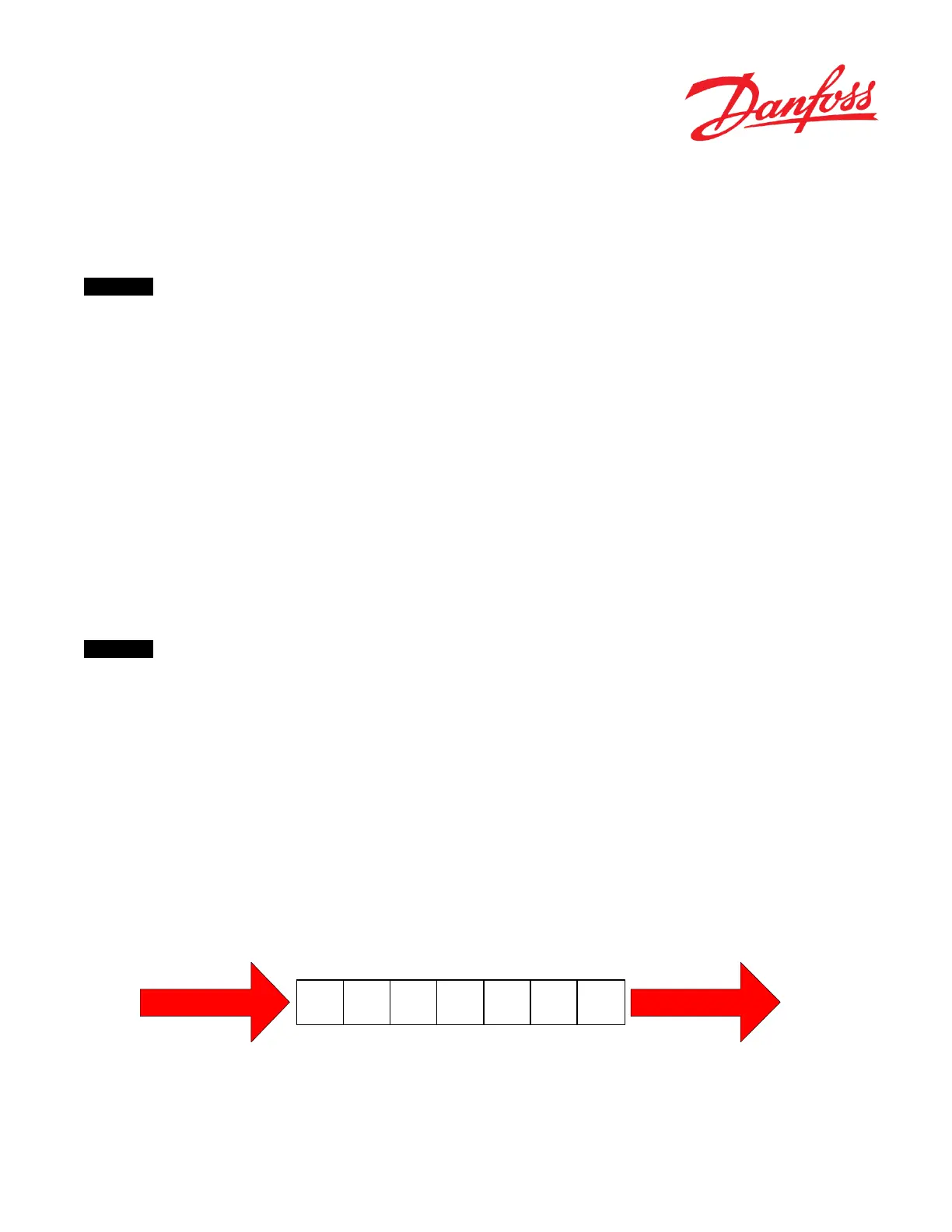

P3810, P3811:

In most cases, it requires several attempts to find an acceptable closed loop dead-band edge within a given time frame (to

ensure consistency in the captured/found values).

P3810 defines the vector size for how many attempts (for left- and right-side dead-band edge, respectively) should be

considered, and P3811 defines how many of these attempts needs to be equal to get a successful spool calibration.

First in

First out

110

110

110 115

110

115 110

Figure 25

The above figure shows an example how and acceptable dead-band value of 110 could be achieved using default values

for P3810 = 7, P3811 = 5.

Loading...

Loading...