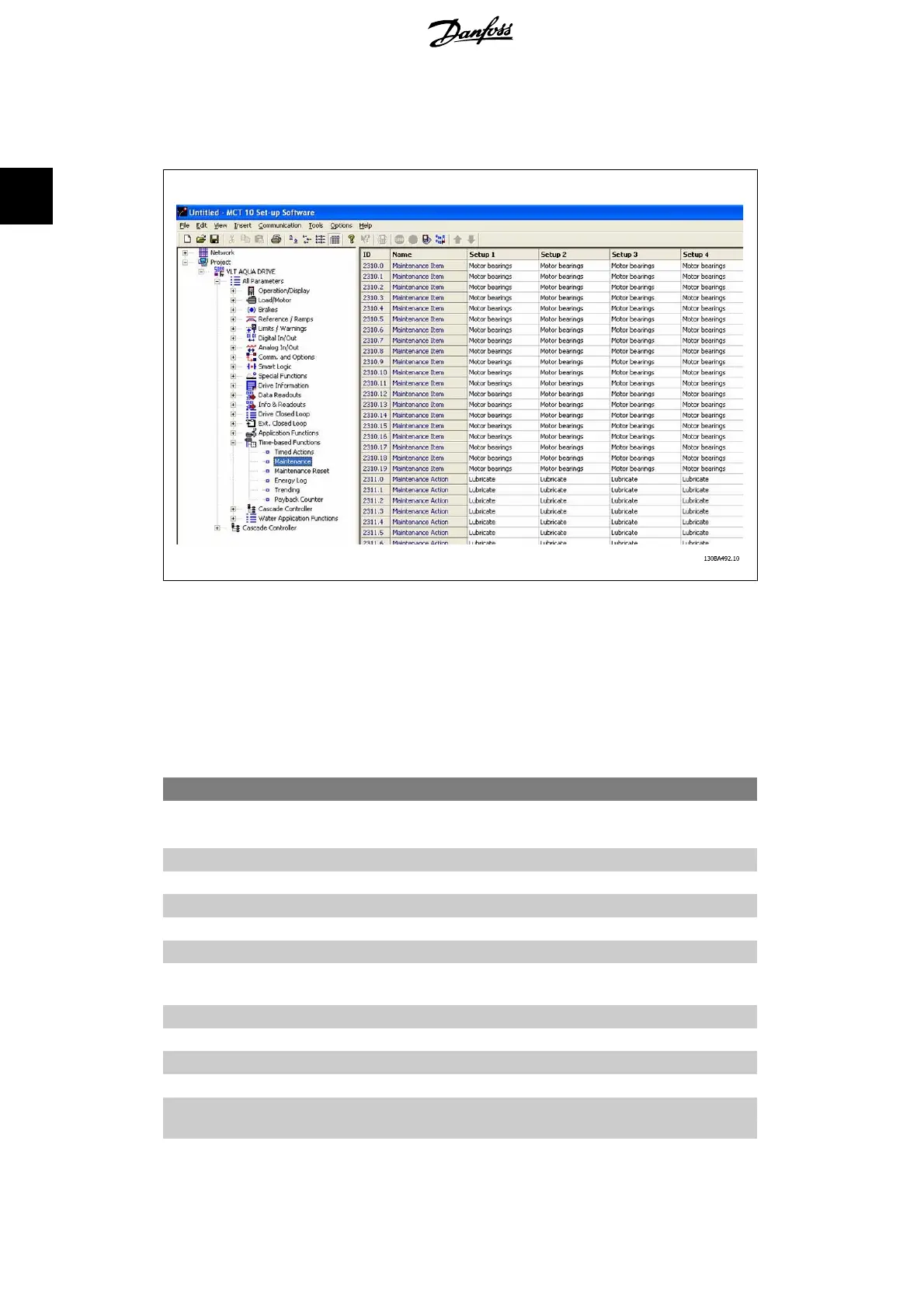

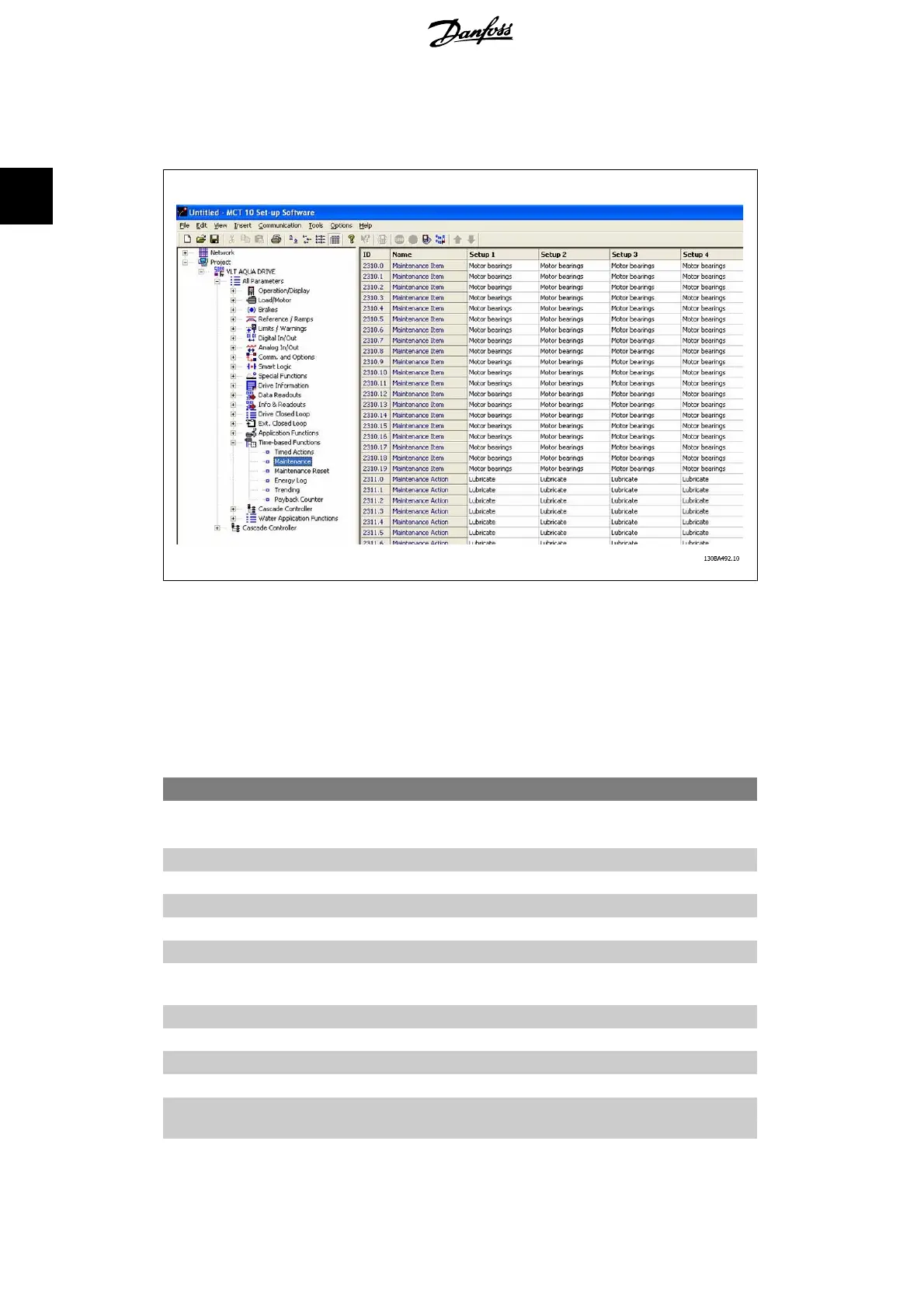

Preventive Maintenance can be programmed from the LCP, but use of the PC-based VLT Motion

Control Tool MCT10 is recommended.

The LCP indicates (with a wrench-icon and an “M”) when it is time for a Preventive Maintenance

Action, and can be programmed to be indicated on a digital output in parameter group 5-3*. The

Preventive Maintenance Status may be read in par. 16-96

Prev. Maintenance Word

. A Preventive

Maintenance indication can be reset from a digital input, the FC bus or manually from the Local

Control Panel through par. 23-15

Reset Maintenance Word

.

A Maintenance Log with the latest 10 loggings can be read from parameter group 18-0* and via

the Alarm log button on the LCP after selecting Maintenance Log.

23-10 Maintenance Item

Option: Function:

[1]

*

Motor bearings

[2] Fan bearings

[3] Pump bearings

[4] Valve

[5] Pressure transmitter

[6] Flow transmitter

[7] Temperature trans-

mitter

[8] Pump seals

[9] Fan belt

[10] Filter

[11] Drive cooling fan

[12] Drive system health

check

2. Parameter Description VLT

®

AQUA Drive Programming Guide

216

MG.20.O2.02 - VLT

®

is a registered Danfoss trademark

2

Loading...

Loading...