Introduction of E-Cam Operation ASDA Series Application Note

2-36 March, 2015

360

o

= 2 W + 2Acc + 2S +Y

S

o

^S) * 360 / (P5-82)

S

o

S

P5-82=72

1234

10

o

20 40

o

80

o

Y

3

360 = 2 W + 2Acc + 2S

o

+Y

S ^S) * 360 / (P5-82)

S

S

P5-82=72

1234

10 20

o

40 80

Y

3

=(=(22

WW AccAcc

S

°

S

AccAcc S

°

WW

360

°

360

°

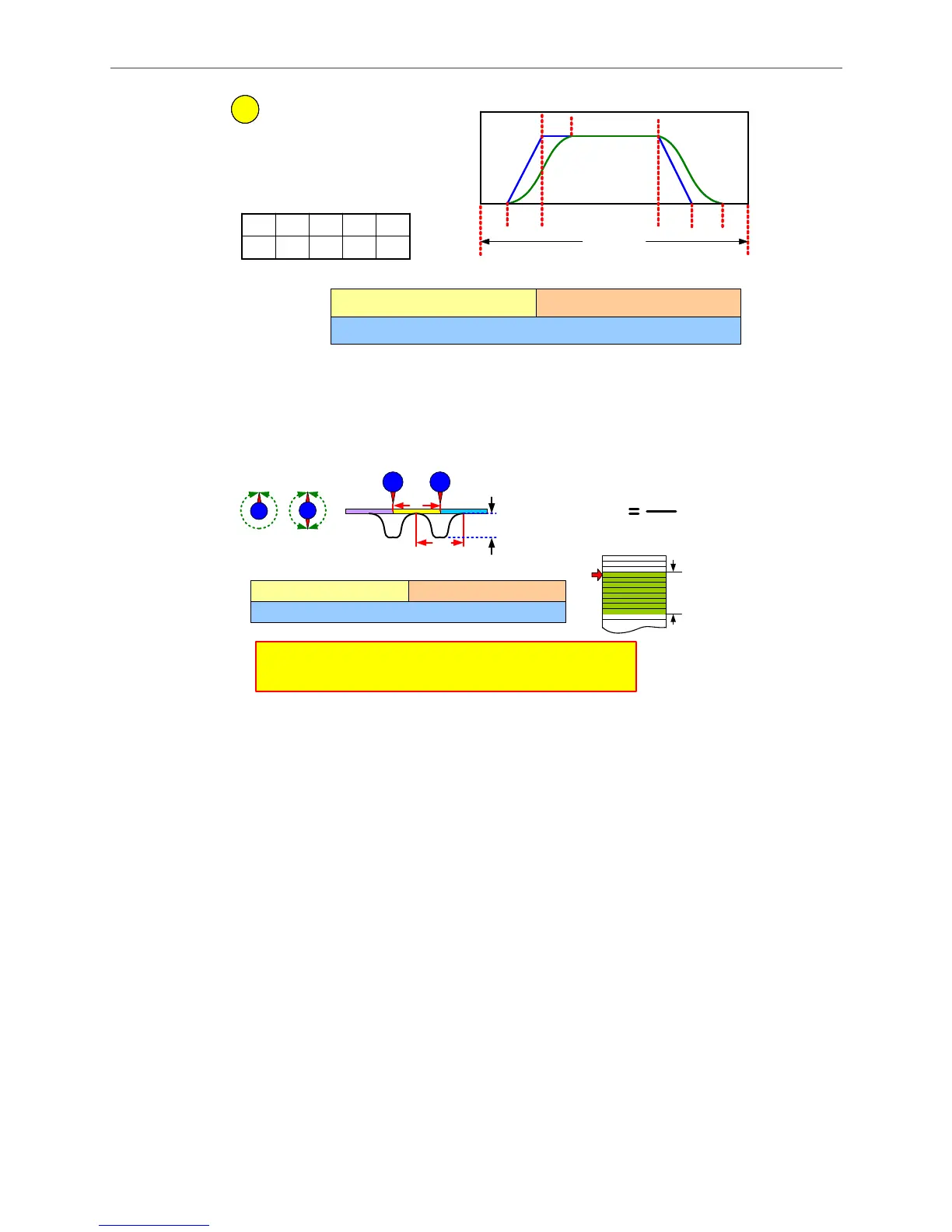

16 bits (S level, 1~4) 16 bits (W ,0~170º)

P5-93

32 bits (Y, Constant Speed Area, 0~330º, Decimal)

P5-94

P5-93.H (Hex.) P5-93.L (Hex.)

Figure 2.52 Setting Proportion of Each Speed Area of Rotary Shear Curve when Using Macro 7

Since the waiting area is adjustable, there are more limitations when creating E-Cam curve

by Macro 7. See Figure 2.53.

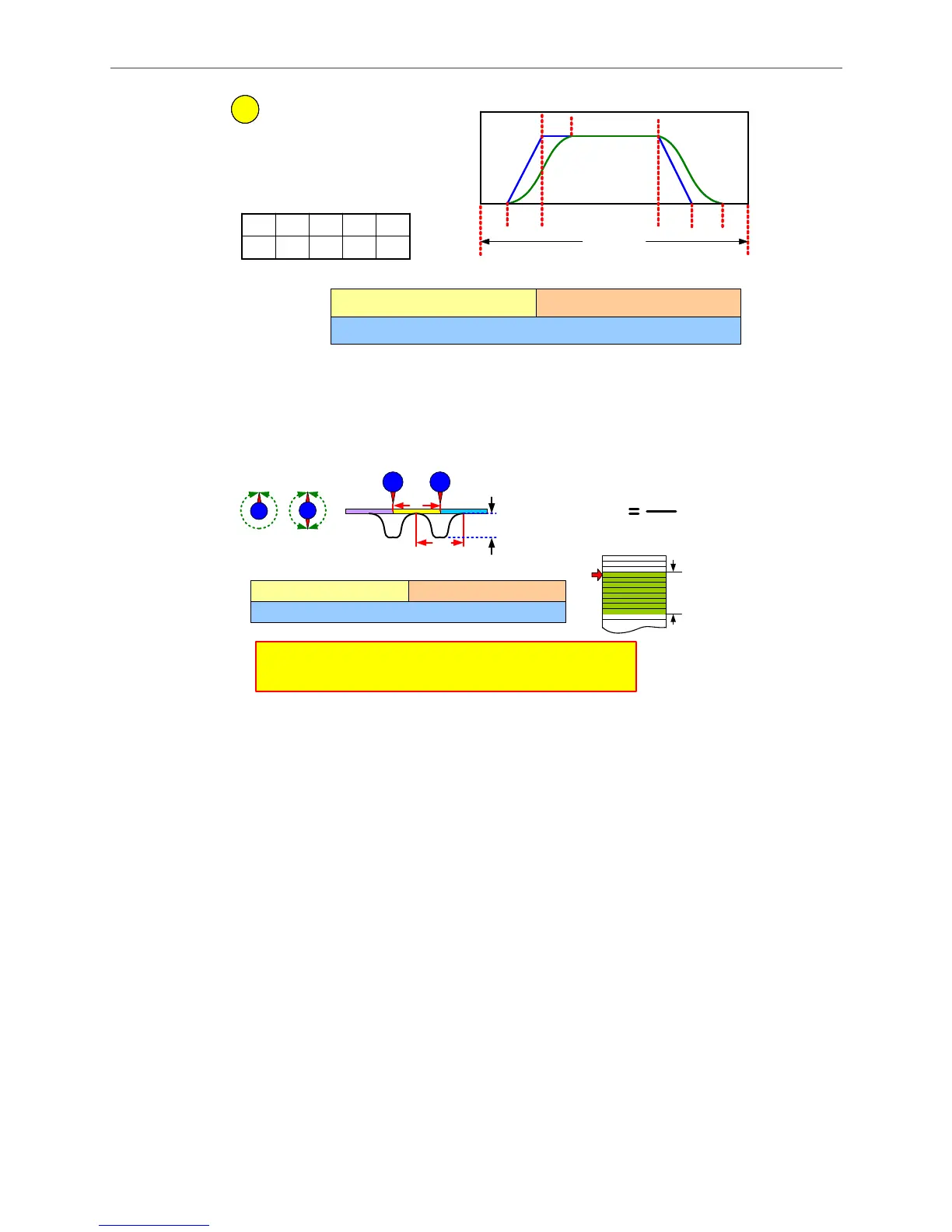

Figure 2.53 Limitations of Creating E-Cam Curve for Rotary Shear by Macro 7

Step 4: See Figure 2.54. Figure out the mechanical specifications and enter relevant

parameters. The required specification data is the same as that needed when creating

E-Cam curve for rotary shear. Users may use HMI to enter the data or use HMI or PLC to

calculate relevant values and download them to the servo drive.

16 bits (S level, 1~4) 16 bits (W ,0~170º)

P5-93

32 bits (Y, Constant Speed Area, 0~330º, Decimal)

P5-94

P5-93.H (Hex.) P5-93.L (Hex.)

360º = 2W + 2Acc + 2Sº +Y

a

a

a

A

A

a

W’ = 180 + 360/(P5-82) - 360/R + (P5-94)/2

R (Length Ratio)

A

a

W < W’, Error Code F07A, enlarge waiting zone or

narrow constant speed area.

W = W’, The starting speed of the curve = 0.

W > W’, The starting speed of the curve > 0.

P5-82 = 30~72

Data Array

Loading...

Loading...