ASDA Series Application Note Introduction of E-Cam Operation

March, 2015 2-35

Macro 7 (E-Cam curve for rotary shear with adjustable sealing zone.)

When using flat cutters which cutting length is changed, the width of the cutter usually

remains the same. However, different material will change the cutting length and angle in

synchronous zone because this area is determined by material. This is an important reason

why this macro command is created. When using Macro 7 and the material has to be

changed, the setting can be completed by re-specifying the cutting length and specifying

whether speed compensation is needed. Steps to set up are shown below.

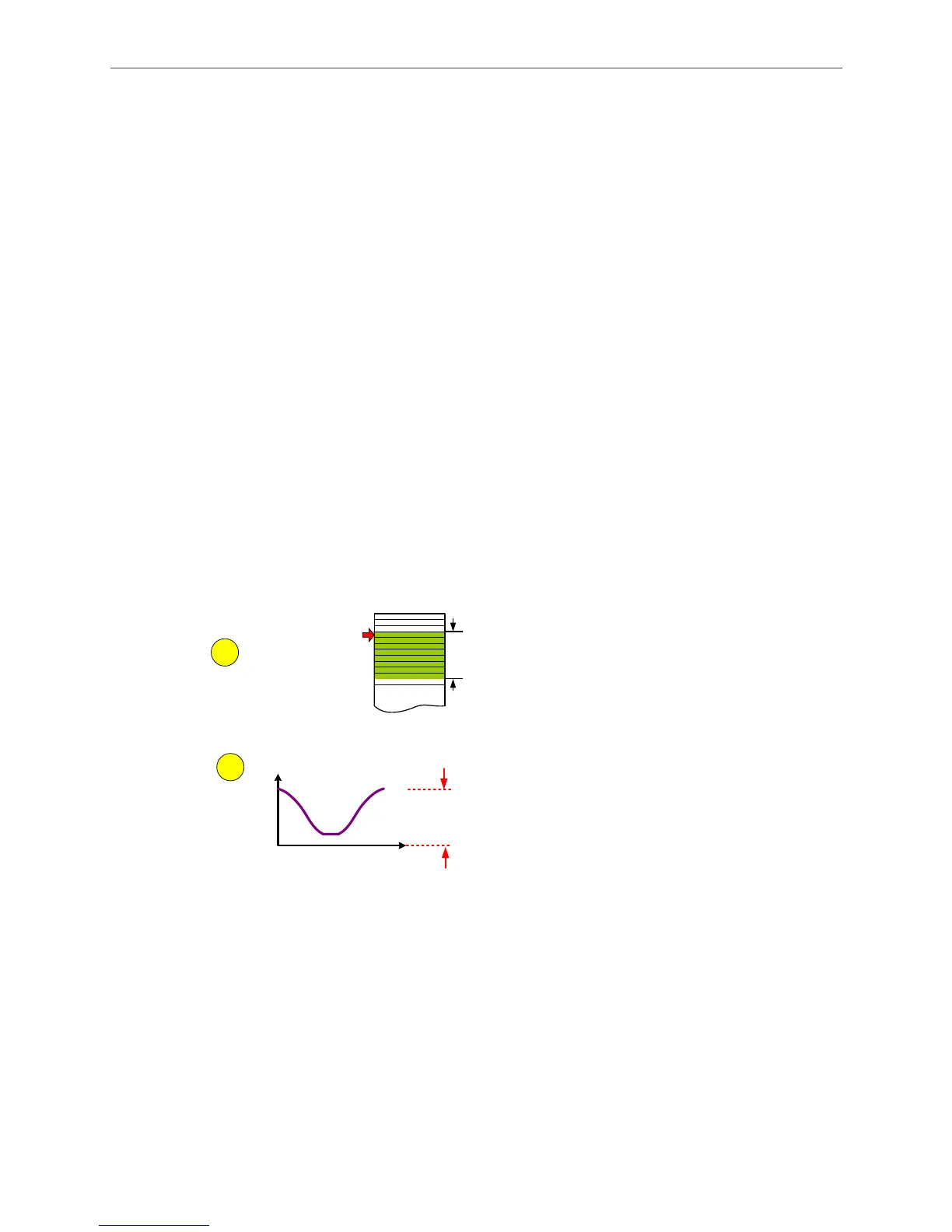

Step 1: The first step is to store the required relevant parameters in data array in order to

create an E-cam curve. P5-81 (the start address of saving the E-Cam curve in data array)

and P5-85 (engaging timing) are included. What’s different from Macro 6 is that value of

P5-82 is an adjustable variable, which range is from 30 to 72 when using Macro 7. That is,

the E-Cam can be divided into 30 ~ 72 parts. To obtain the best resolution, set the area

number to 72 is recommended.

Step 2: The second step is to specify the scaling of E-Cam curve, which includes system’s

E-gear ratio P1-44/P1-45 (E-Cam is part of the system thus it might be changed by the

system’s E-gear ratio.) and scaling of E-Cam curve (P5-19).

P5-82 = 30~72 (30+1 ~ 72+1 items)

(Highly recommend to set P5-82 to 72.)

P5-81

The starting

address

P5-85 = 0

Data Array

1

2

Position (PUU)

Slave

Master (Pulse)

Slave E-Gear:

The scaling of E-Cam curve when output.

P1-44, P1-45, P5-19

Figure 2.51 Relevant Parameter Settings for E-Cam Curve when Using Macro 7

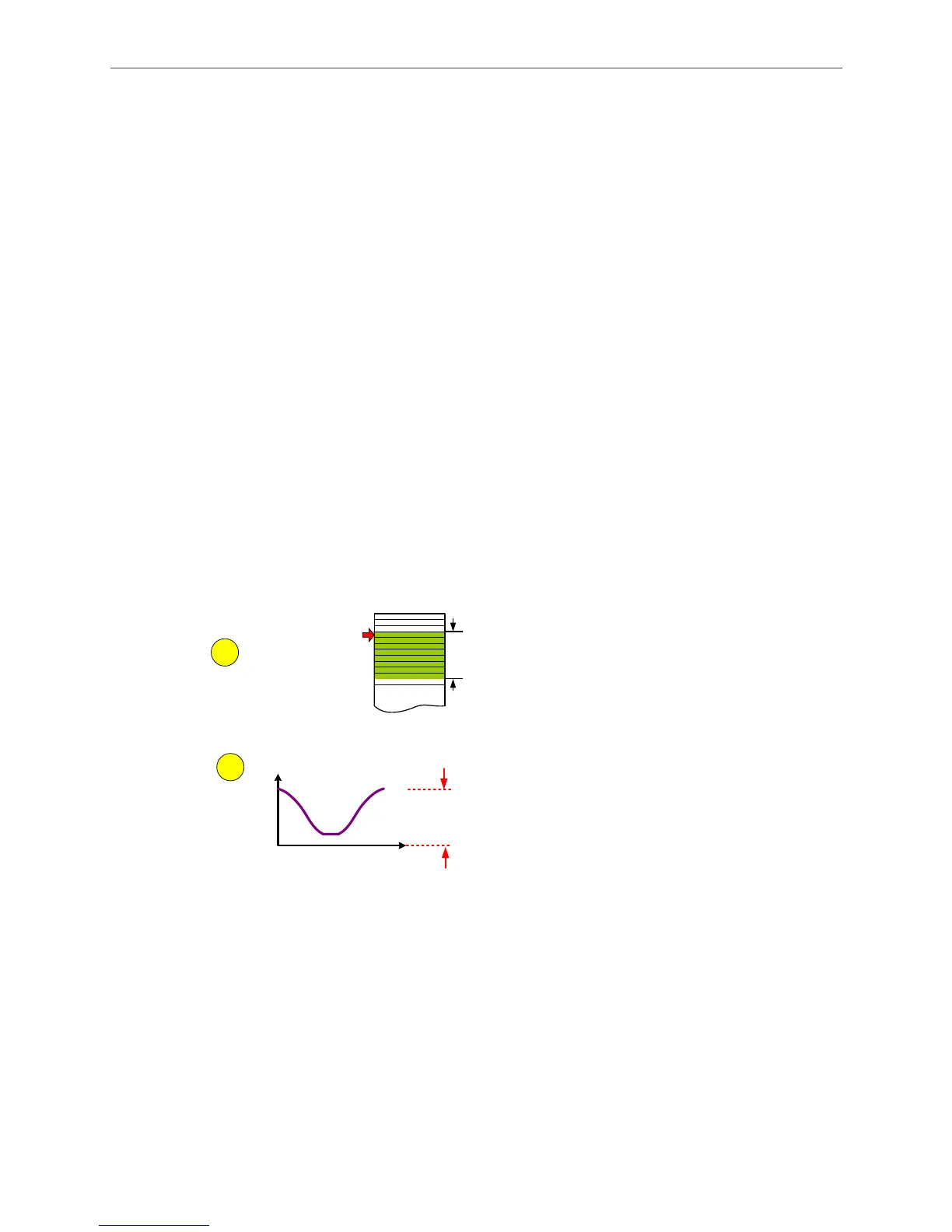

Step 3: Specify proportion of each speed areas on E-Cam curve. As the size of constant

speed area on E-Cam curve is adjustable, other areas such as acceleration/deceleration

area, S-curve, and Stop area have to be set manually. The setting proportion of each area

has to be appropriate in order to operate smoothly. The function of S-curve is to smooth the

curve when speed changes. Its setting is level- based, which is from 1 to 4. Others are

specified according to its angle.

Loading...

Loading...