Introduction of E-Cam Operation ASDA Series Application Note

2-34 March, 2015

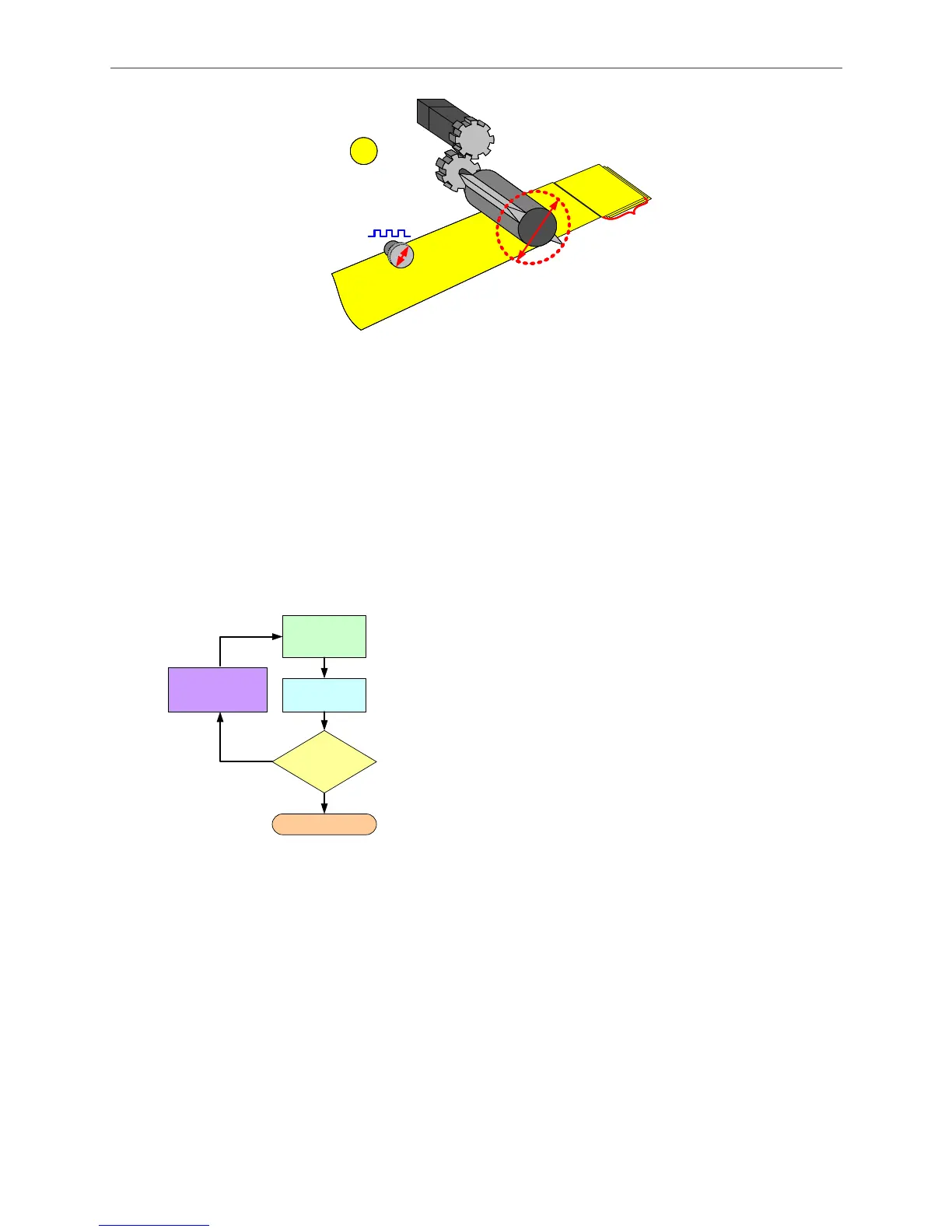

Gear Box

Tooth #A

(to motor)

Tooth#B

Cutting

Length

L

Diameter

d1

編碼器直徑

d2

Encoder pulse

number per

revolution

N

切刀的數目

C

3

P5-84 = N / (

π

* d2 (mm) ) * L ( mm) ,

P5-83 = 1

P5-94 = A * C

P5-95 = B

P5-96 = L (m m) / (* d 1 (mm) ) * C * Vc *

Vc = Speed compensation

Vc =1 Do not compensate

π

#A

#B

(to cutter)

L

d1

Diameter

d2

N

Number of

cutter

C

3

P5-84 = N / (

π

* d2 (mm) ) * L ( mm) ,

(Pulse number required for L)

P5-83 = 1

P5-94 = A * C

P5-95 = B

P5-96 = L (m m) / (* d 1 (mm) ) * C * Vc *

Vc =

π

10000001000000

Vc = 0.9, Slow down to 90 %, Vc = 1.1 Speed up to 110%

Figure 2.49 Mechanical Settings when Using Macro 6

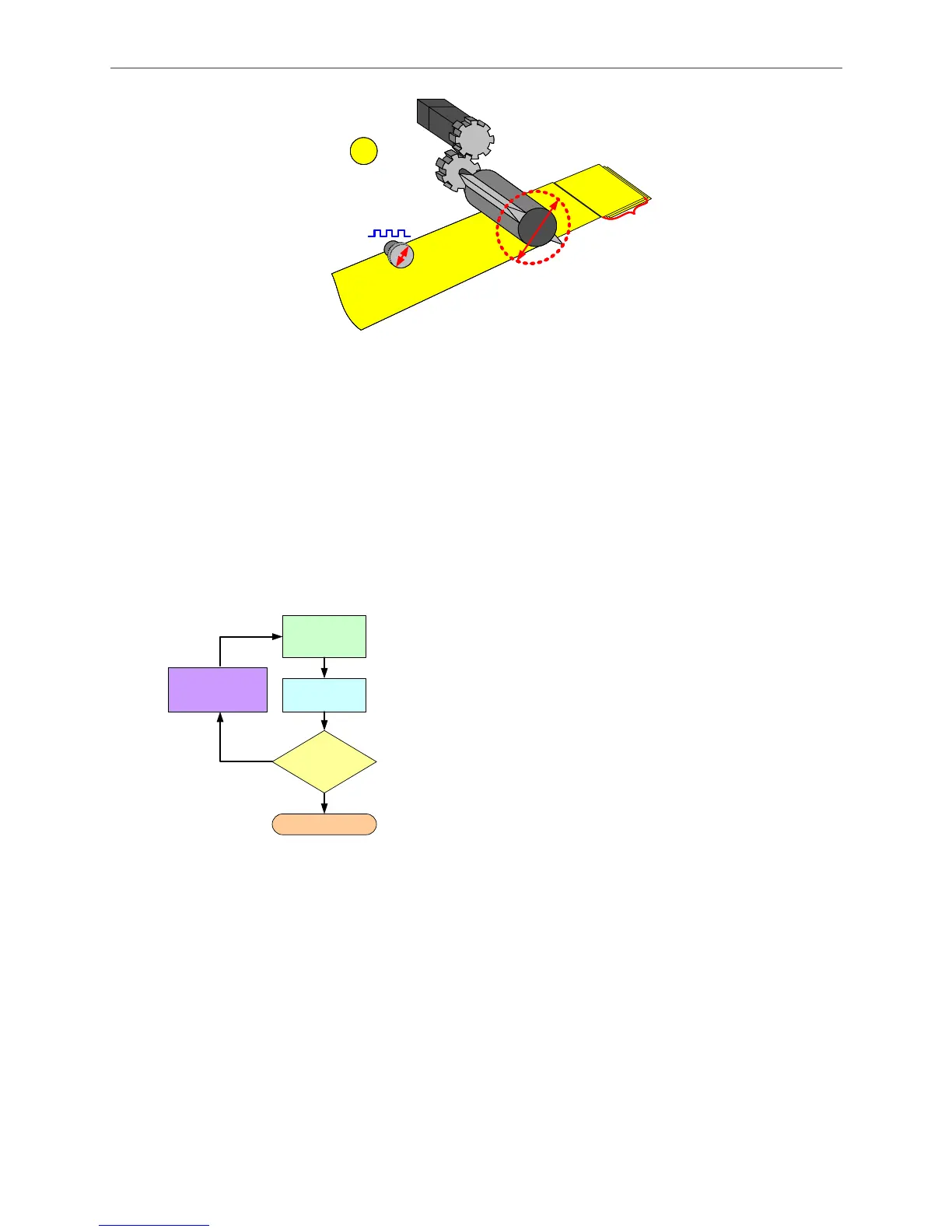

Step 4: When all relevant parameters are set, write 6 to P5-97 to enable macro 6. After macro is

enabled, read P5-97 again. If its value is 0x1006, it means the table is successfully created by

the macro. If error codes are shown, please correct the parameter value according to the error

message.

Figure 2.50 Enable Macro Command 6

After the curve is created successfully, it can be used to enable the E-Cam. When system

setting is complete, most of the mechanical specification will not be changed. The parts that

will be modified might be the setting of cutting length of the material and speed

compensation. If the cutting length has to be changed, the setting can be done by entering

the new value of cutting length and relevant parameters. After enabling the macro (P5-97 =6),

a new E-Cam curve can thus be used. With this method, it is easy to modify relevant

settings.

Write P5-97 = 6

Read P5-97

P5-97 = 0x1006 ?

Modify the parameter

value according to the

error message

Success

True

False

List of error codes from P5-97 for #6 macro command

F061h: E-Cam engaged. Unable to create a table.

F062h: Value of P5-94 exceeds the range of 1~65535.

F063h: Value of P5-95 exceeds the range of 1~65535.

F064h: Value of P5-96 exceeds the range of 300000~250

F065h: Inappropriate address. Value of P5-81 exceeds

the range.

F066h: Value of P5-82 must be 7.

F067h: Value of E-gear ratio is too high. Lower the

value but keep the original ratio of P1-44 and

P1-45. (1280:100 128:10)

Loading...

Loading...