ASDA Series Application Note Application Examples

March, 2015 3-53

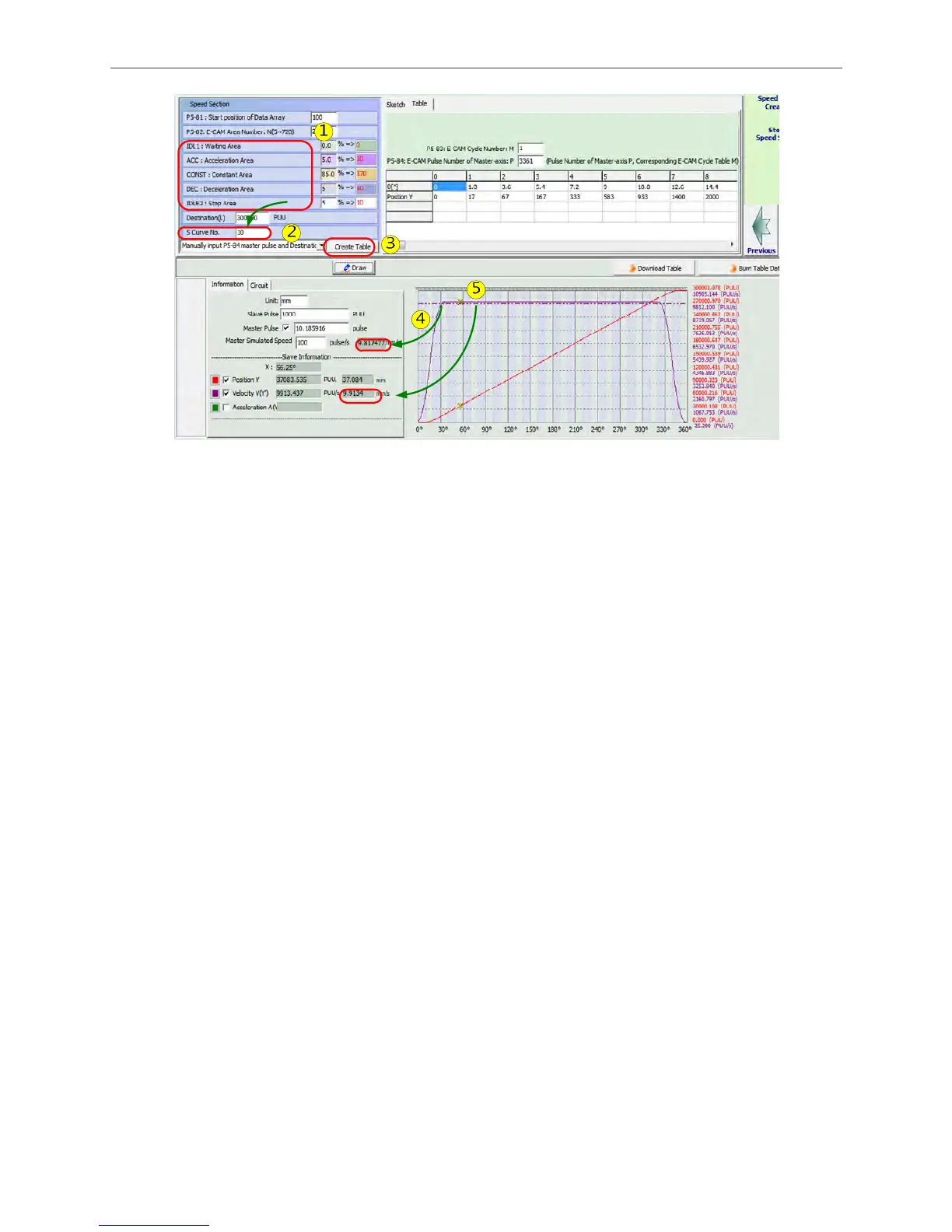

Figure 3.3.19 Create E-cam curve

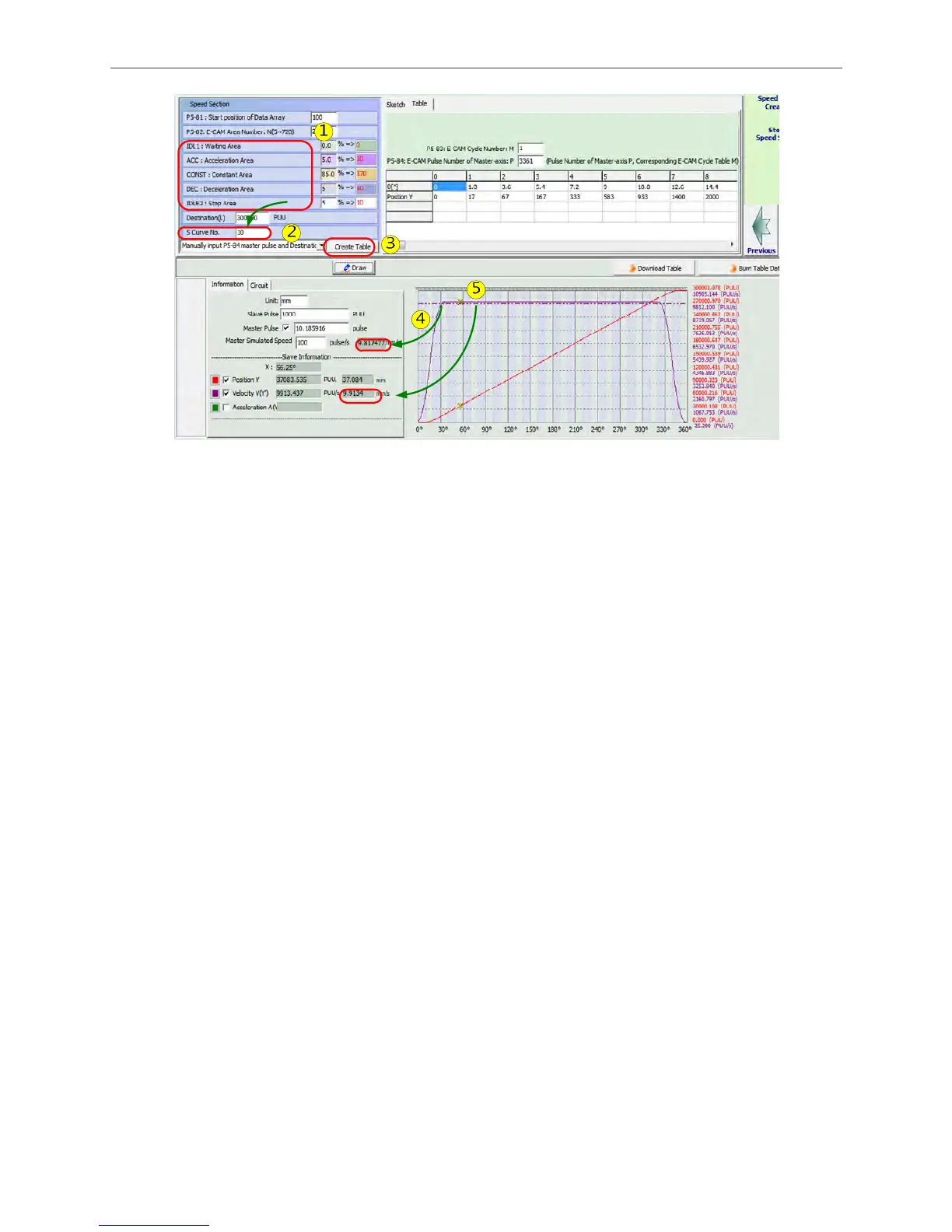

f. Use camshaft axis to adjust the speed in Constant Speed Area

To adjust the curve by Acceleration / Deceleration Area or slave axis lead will be introduced

here (Both can be adjusted simultaneously.). In Figure 3.3.20, after adjusting Acceleration /

Deceleration Area, the Constant Speed Area of camshaft axis can comply with the speed of

master axis (Please see the result in mark 4 and 5 in Figure 3.3.20.). During the process, several

times of trying for a proper value are needed. This method is suitable for unchangeable pulse

number of master axis (P5-84). Without saying, the value of P5-84 can be changed in the

application of labeling machine. From Figure 3.3.21, users can acquire the desired speed curve

by adjusting camshaft axis lead (mark 1). From mark 4 and 5 in 3.3.21, users could know that the

speed of master axis is 9.817477387 ≒ which is the same as slave axis in Constant Speed

Area.

In Figure 3.3.20, the length of Constant Speed Area is 300000 PUU * (360°-60°) / 360° /

1000(PUU/mm) = 250 (mm), which is longer than 23 cm. 60° is the time for Acceleration /

Deceleration Area.

In Figure 3.3.21, the length of Constant Speed Area is 298600 PUU * (360°-65°) / 360° /

1000(PUU/mm) = 244.69 (mm), which is longer than 23 cm. 65° is the time for Acceleration /

Deceleration Area.

Loading...

Loading...