Application Examples ASDA Series Application Note

3-52

March, 2015

d. Set master axis lead

It is estimated that master axis will travel 33 cm (10% more). Therefore, if P5-83 is set to 1, then

P5-84 = 10.185916(pulse/mm)*330(mm) = 3361.

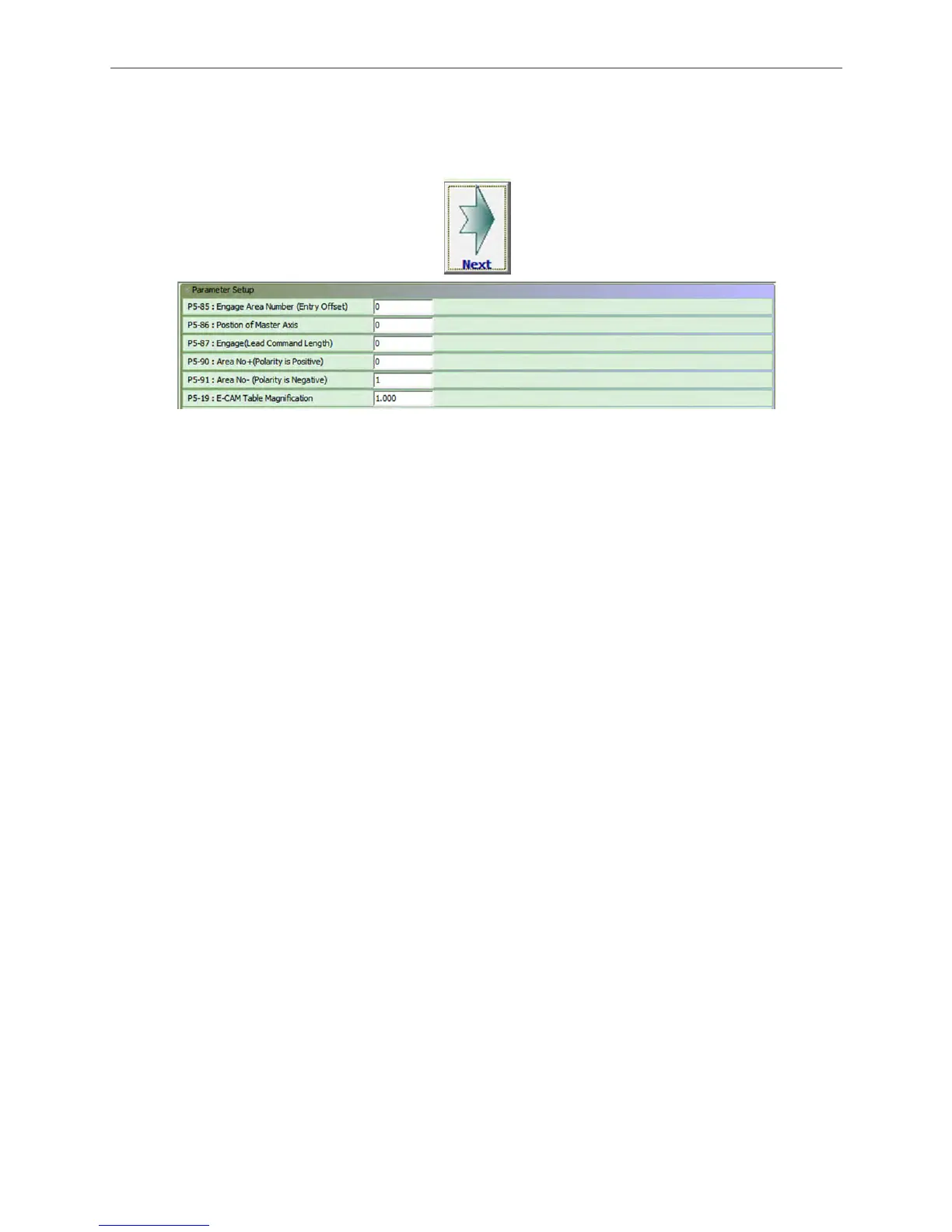

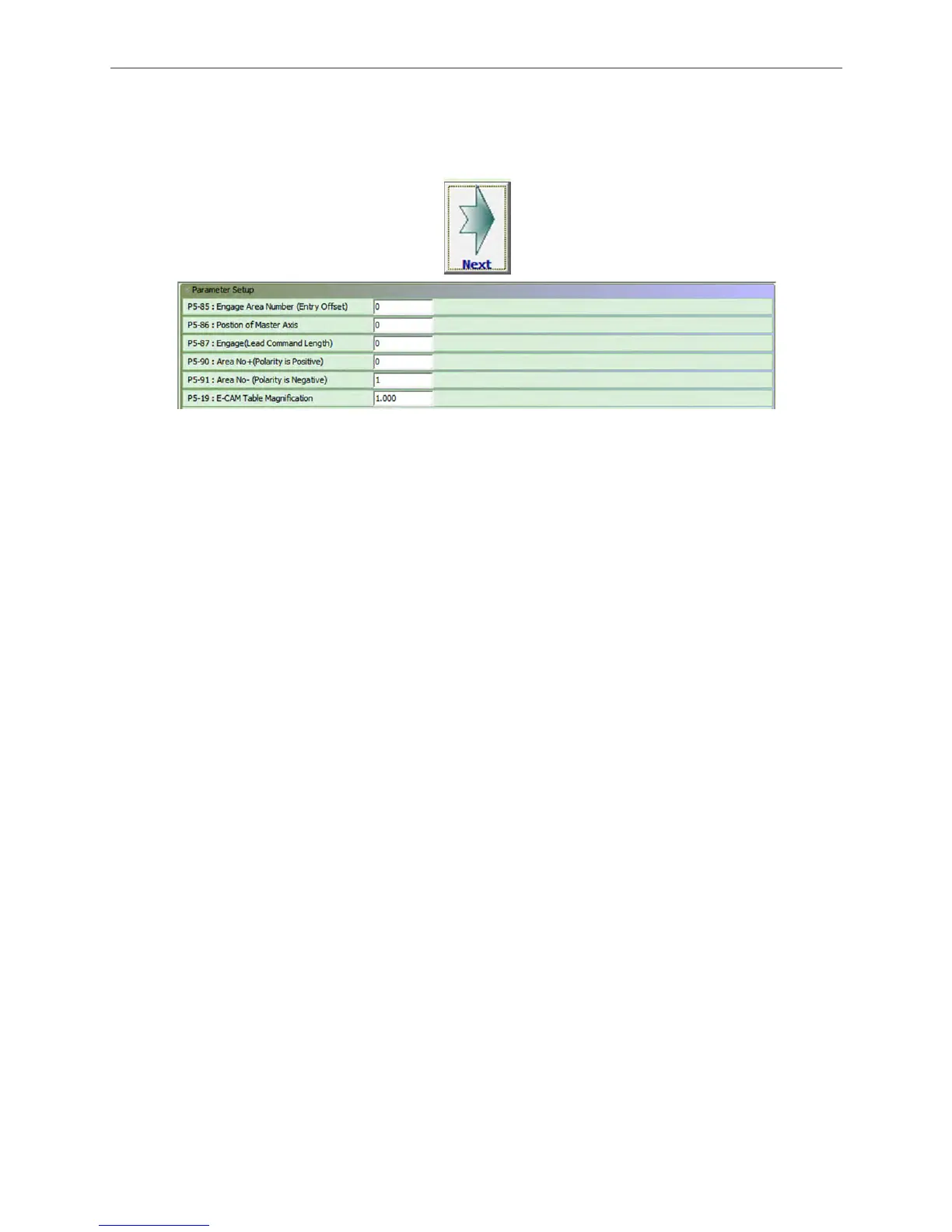

Figure 3.3.18 Pulse number setting of master axis

e. Create an E-cam curve

Refer to mark 1 in Figure 3.3.19, setup Waiting Area, Acceleration Area, Constant Speed

Area, Deceleration Area and Stop Area. Among the setting, motor inertia ought to be

considered in Acceleration / Deceleration Area. If the motor inertia is larger, the acceleration /

deceleration curve will be steeper which might result in command delay, motor overload or

regeneration error. Thus, if acceleration / deceleration cannot be calculated precisely, do field

test first. In addition, when creating curve, a longer Constant Speed Area is more ideal, since it

is applied in real working area. Meanwhile, it is better to leave some time for Stop Area;

otherwise, it might be unable to complete homing. See mark 2 in Figure 3.3.19, the setting of S

Curve No. is for smooth E-cam curve so that the command will not be changed dramatically. The

ideal setting value is equal to the value of Stop Area, such as 10. Then, press Create Table

which is marked 3, the system will create the table and the curve.

Mark 4 shows the speed of master axis is 9.817477387, which is the target speed the camshaft

needs to follow (This value varies with Master Simulation Speed, but it will not influence the

curve creating.). Move the cursor to Constant Speed Area, see mark 5. In speed field, the value

is 9.867 (>9.8174477387, Master Simulation Speed). Thus, the speed of camshaft axis is slightly

faster than master axis. Users can adjust Acceleration / Deceleration Area or master / slave

axis lead to make the two values the same.

Loading...

Loading...