ASDA Series Application Note Application Examples

March, 2015 3-51

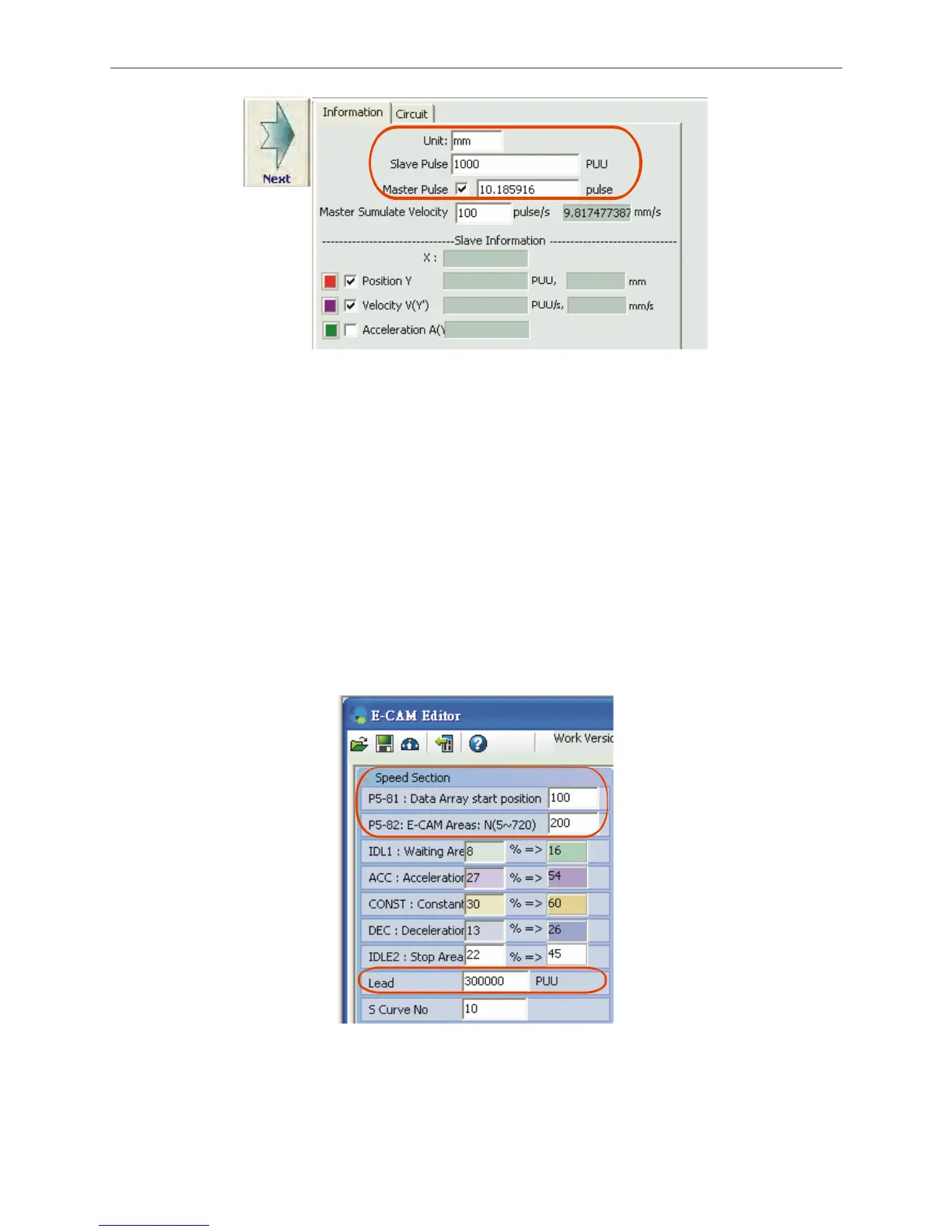

Figure 3.3.16 Simulation information

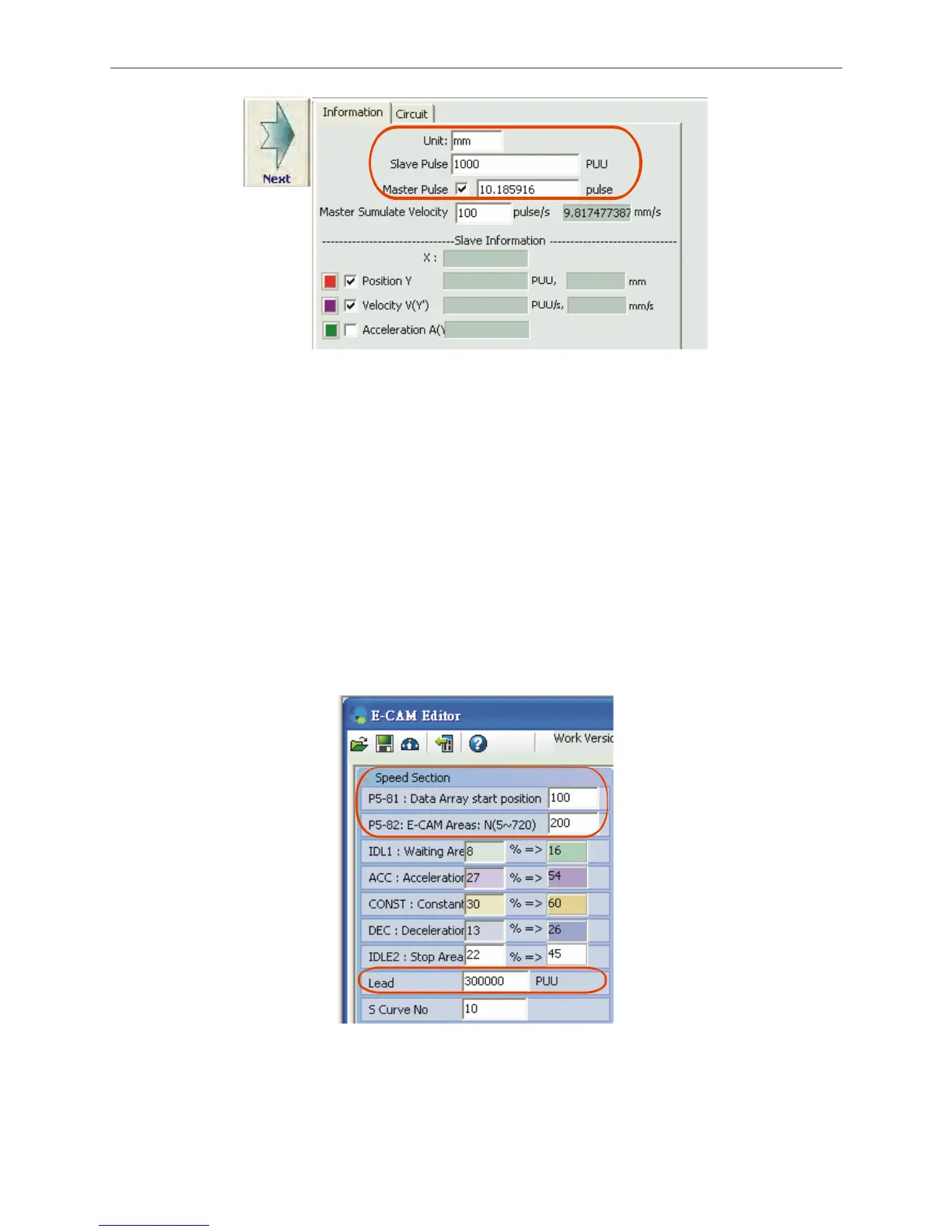

c. Set slave axis lead

Setup the longest lead of labeling, 23 cm and consider the acceleration / deceleration section,

this curve must be designed longer than 23 cm. According to the previous experience, take 30

cm for a rough estimation (About 10% more, including 5% of acceleration and 5% of

deceleration). Thus, the calculation is 300(mm)* 1000 (Pulse/mm) = 300000 Pulse. Fill this value

into Lead. In addition, fill 100 into P5-81, Data Array start position, which can be set according to

the actual condition.

Fill 200 into P5-82, E-CAM Areas: N(5~720). The bigger the value is, the more perfect the curve

will be. It is suggested to fill in 200 at least. Users can set different values to see different results.

See Figure 3.3.17.

Figure 3.3.17 Setting of E-cam lead

Loading...

Loading...