Application Examples ASDA Series Application Note

3-112 March, 2015

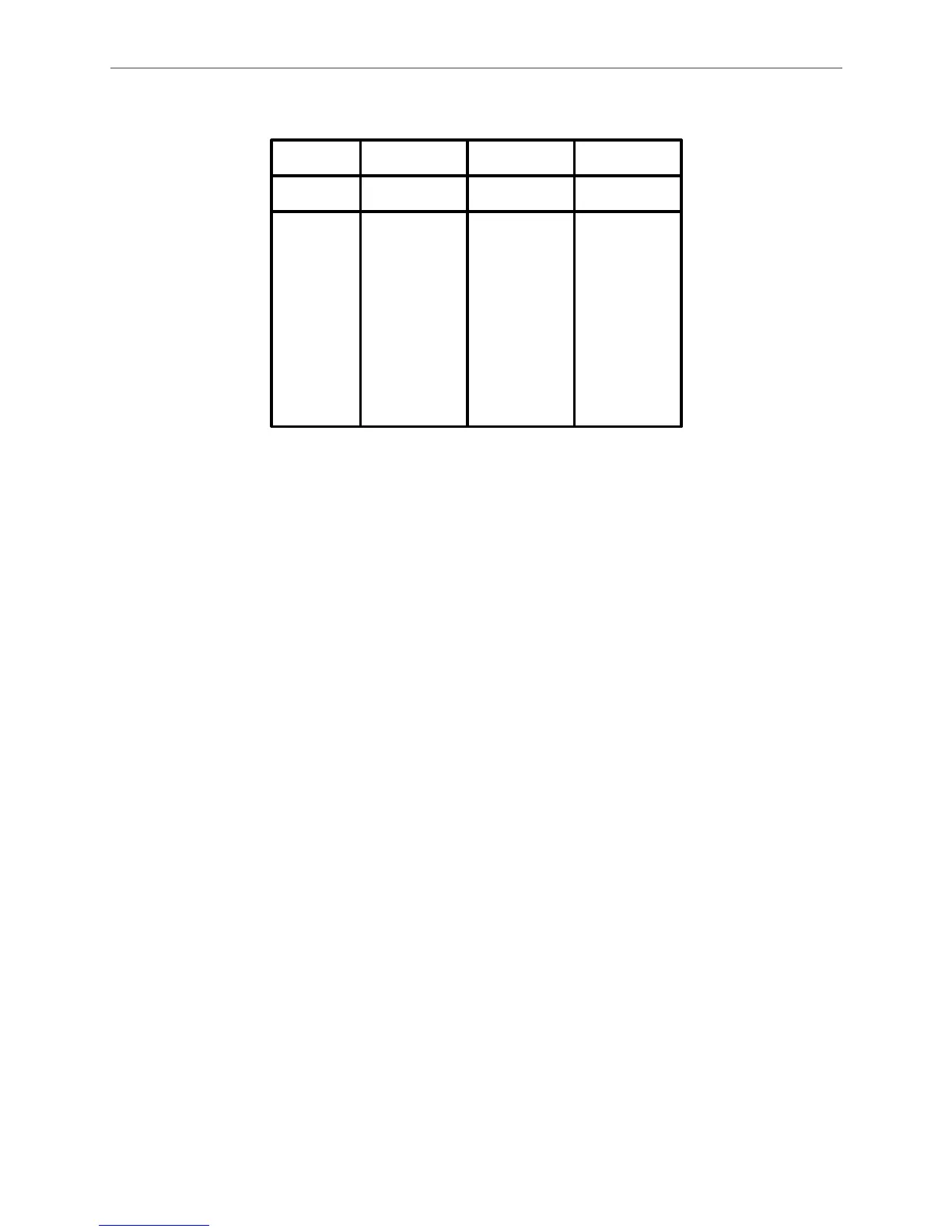

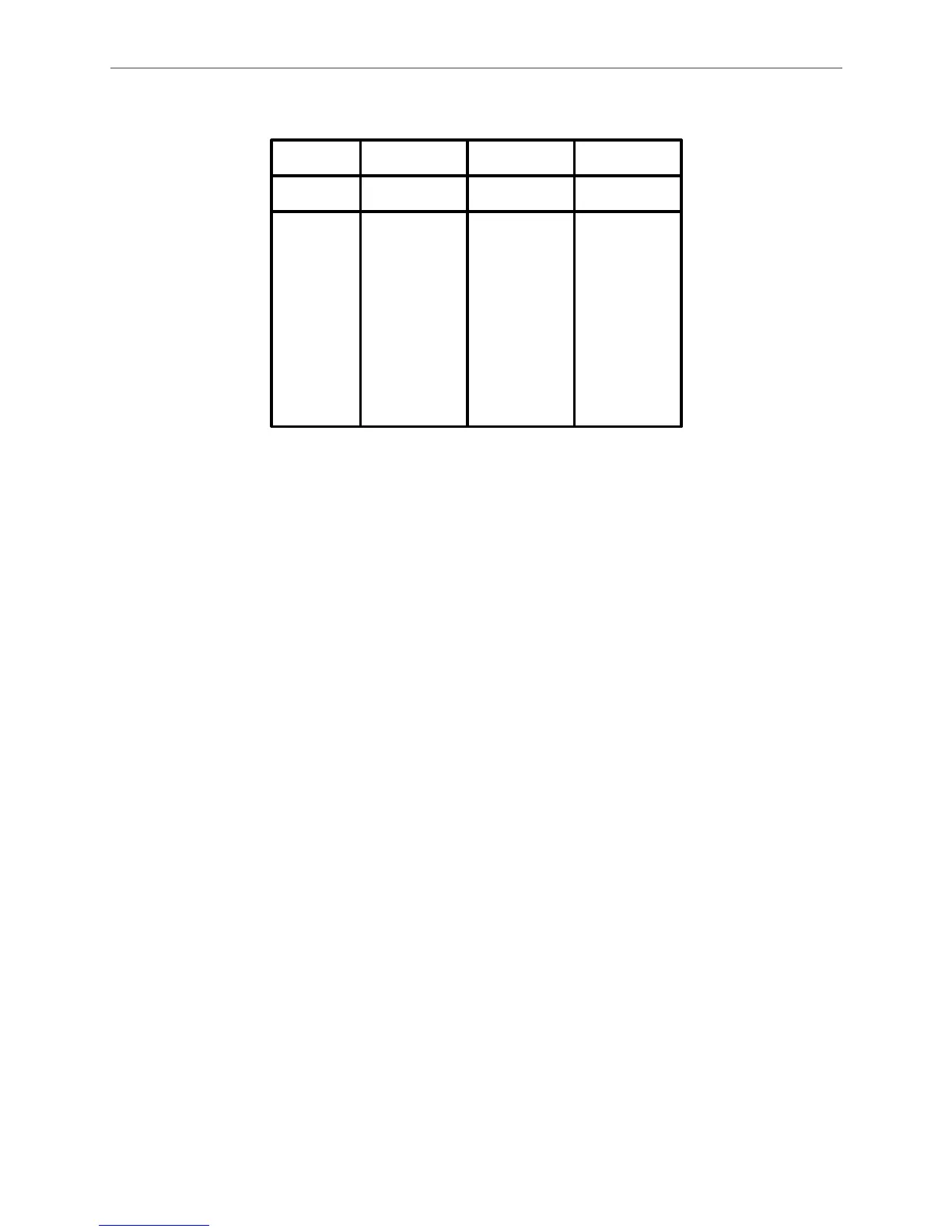

P2-76.X

Bit

Function

Description

012

Two point

phase

0

:

Single point

correction

1

:

Adjust the

phase of

material

feeding axis

trigger PR

immediately

0

:

Manually

trigger PR set

by P2-73.BA

1

:

When

DI.ALGN

signal enters,

PR set by P2-

73.BA will be

triggered

automatically

_

Enable

registration

0: disable

1: enable

Figure 3.8.11 Setting to enable E-cam

In Figure 3.8.11:

P2-76.X0 is the switch of positioning. When P2-76.X0 = 1, positioning function is enabled.

P2-76.X1 is for setting up the triggering time of adjusting PR (PR set by P2-73.BA).

Assume P2-76.X1 = 1, when the signal of DI.ALGN is triggered, if the system detects the

error, the system will write the error into PR set by P2-73.BA and execute PR to correct the

error automatically. If P2-76.X1 = 0, when DI.ALGN signal is triggered, the system will still

write the error into PR set by P2-73.BA. However, PR will not be executed automatically.

The user has to judge the execution time and manually trigger PR.

P2-76.X2 is for reading the relation of marks and camshaft. Take figure 3.8.12 as the

example. The cutter axis of ‘mechanism a’ is the slave axis which travels according to the

E-cam curve. Film feeding axis with marks is the master axis. The sensor of cam

positioning reads the marks on wrapping film which transmits by film feeding axis and

transmits DI.ALGN signal to the cutter axis for adjustment. When the slave axis is doing the

adjustment, it will not influence the transmission of wrapping film. When applying to this

mechanism, please set P2-76.X2 = 1. For ‘Mechanism b’ in figure 3.8.12, the cutter axis is

the master axis and the film feeding axis is the slave axis. Therefore, the film feeding axis

travels is in accordance with the E-cam curve. DI.ALGN signal needs to be sent to the film

feeding axis. When executing cam positioning, the transmission of wrapping film will be

influenced by the adjustment. Thus, this application needs to set as P2-76.X2 = 1.

Loading...

Loading...