ASDA Series Application Note Application Examples

March, 2015 3-119

mechanism can only operate at forward direction, then this setting should be set as 100%.

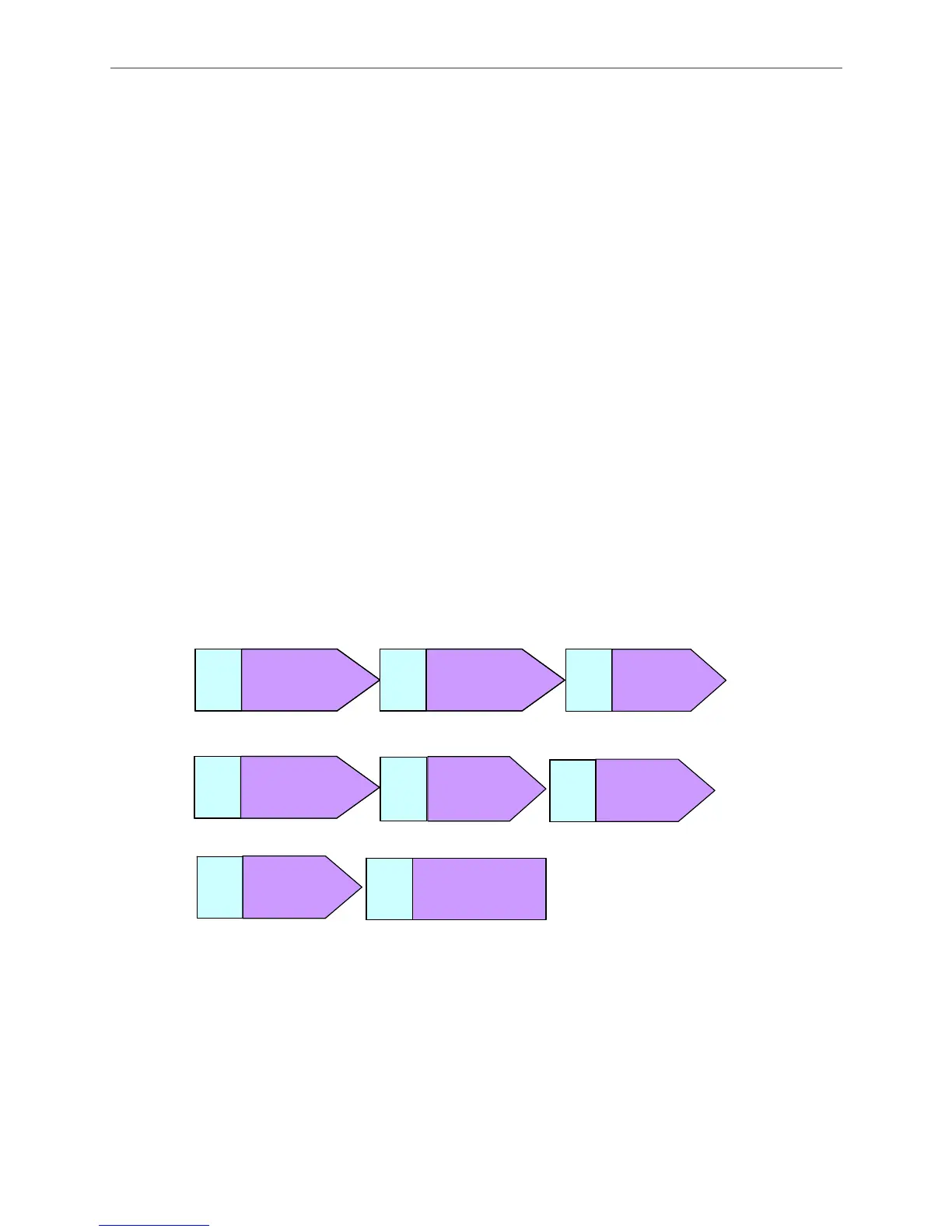

PR#8: Parameter setting of macro F is to set up the alignment target position. Pulse from master

axis is its unit. The setting range is between 0 and (P5-84 / P5-83) – 1.

PR#9: Trigger macro F. This macro will calculate the moving distance between the current

position and target position which is set by P5-96. Then write the moving distance into PR that is

specified by P5-93.

PR#10: Set P5-19 to 0. When the setting value of P5-19 is working, the E-Cam curve will be set

to 0 and the E-Cam will stop operating.

PR#11: Trigger macro 8. It allows the setting of P5-19 (E-Cam scaling) becomes effective when

E-Cam is engaged.

PR#12: Change the E-Cam scaling back to the original one.

PR#13: When triggering macro F, the calculated moving distance will be written into this PR as

the target the position command needs to move. After this PR is triggered, the cutter axis will

move to the position which is set by P5-96.

Enable macro F and calculate

the moving distance of E-Cam

PR

#

2

(I)

PR#6

(1)

Write

DLY = 0 ms

P5-93 = 0x0D

Set up PR of going trip

PR

#

4

(I)

PR#7

(1)

Write

DLY = 0 ms

P5-95 = 40

Available forward rate (%)

PR

#

3

(I)

DL

Y

=0

m

s

P5- =0x

PR#8

(1)

Write

DLY = 0 ms

P5-96 = 0

Set up the position after triggering

macro F and returning to 0 degree

PR

#

4

(I)

DL

Y

=1

m

s

P5- =0x

PR#9

(1)

Write

DLY = 0 ms

P5-97 = 0xF

PR

#

7

(I)

PR#13

(1)

E-Cam moves

Position

D = 0, S = 1500 rpm

0 PUU, INC

PR

#1

2

(I)

PR#10

(1)

Write

DLY = 0 ms

P5-19 = 0

Set up E-Cam curve

and stop E-Cam

PR

#1

2

PR#11

(1)

Write

DLY = 0 ms

P5-97 = 0x8

PR

#1

2

PR#12

(1)

Write

DLY = 0 ms

P5-19 = 1

Resume E-Cam scale

Trigger macro 8 and enable the

setting of P5-19 immediately

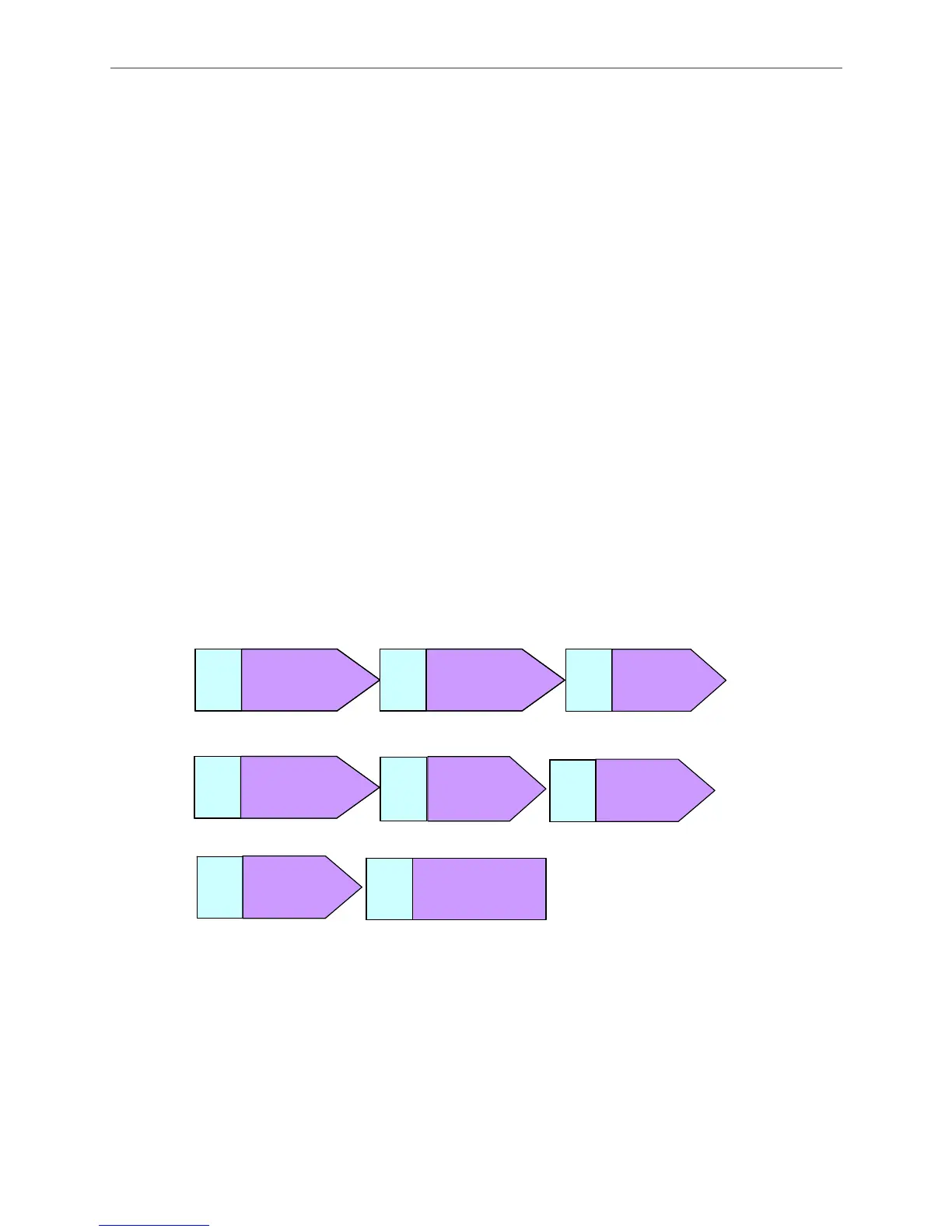

Figure 3.8.22 Anti-cut PR procedure

The time setting of E-Cam disengaged is very important when using this way to avoid mitcut.

P5-88.U should be set to C (8+4), which means to set up cyclic mode and the function to disable

E-Cam after disengaging. Otherwise, macro 8 cannot work. It has to set up P5-88.X1 (Set

P5-88.X to 3 when E-Cam is activated) when E-Cam is engaged. If E-Cam is still engaged

because of alarm or servo off, this setting is to ensure PR#13 can still work when E-Cam stops.

Loading...

Loading...