ASDA Series Application Note Chapter 4 Application Techniques

March, 2015 4-31

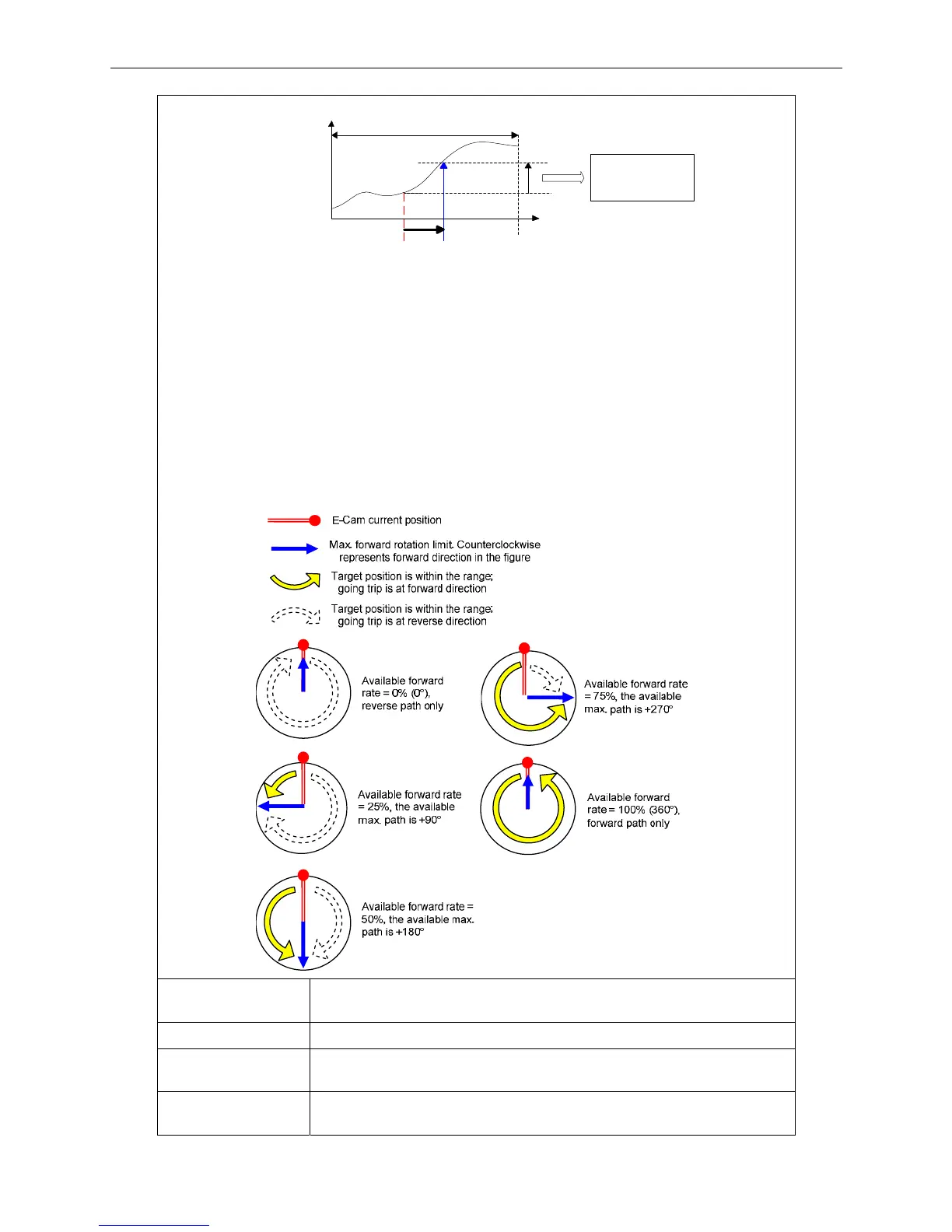

Pulse number of master axis after

rotating a cycle: (P5-84/P5-83) = L

Master axis position (X)

Slave axis

position (Y)

Current

engaged

position

Alignment target

position P5-96

Alignment

correction value

= Y_Diff

*P5-93.UZ is able to limit the max. correction rate. The alignment target position ★ will be

different from P5-96.

| aignment target position★ – current engaged position| / L <= P5-93.UZ %

*DI time delay compensation can be set via P5-94, it can correct the error caused by different

operation speed.

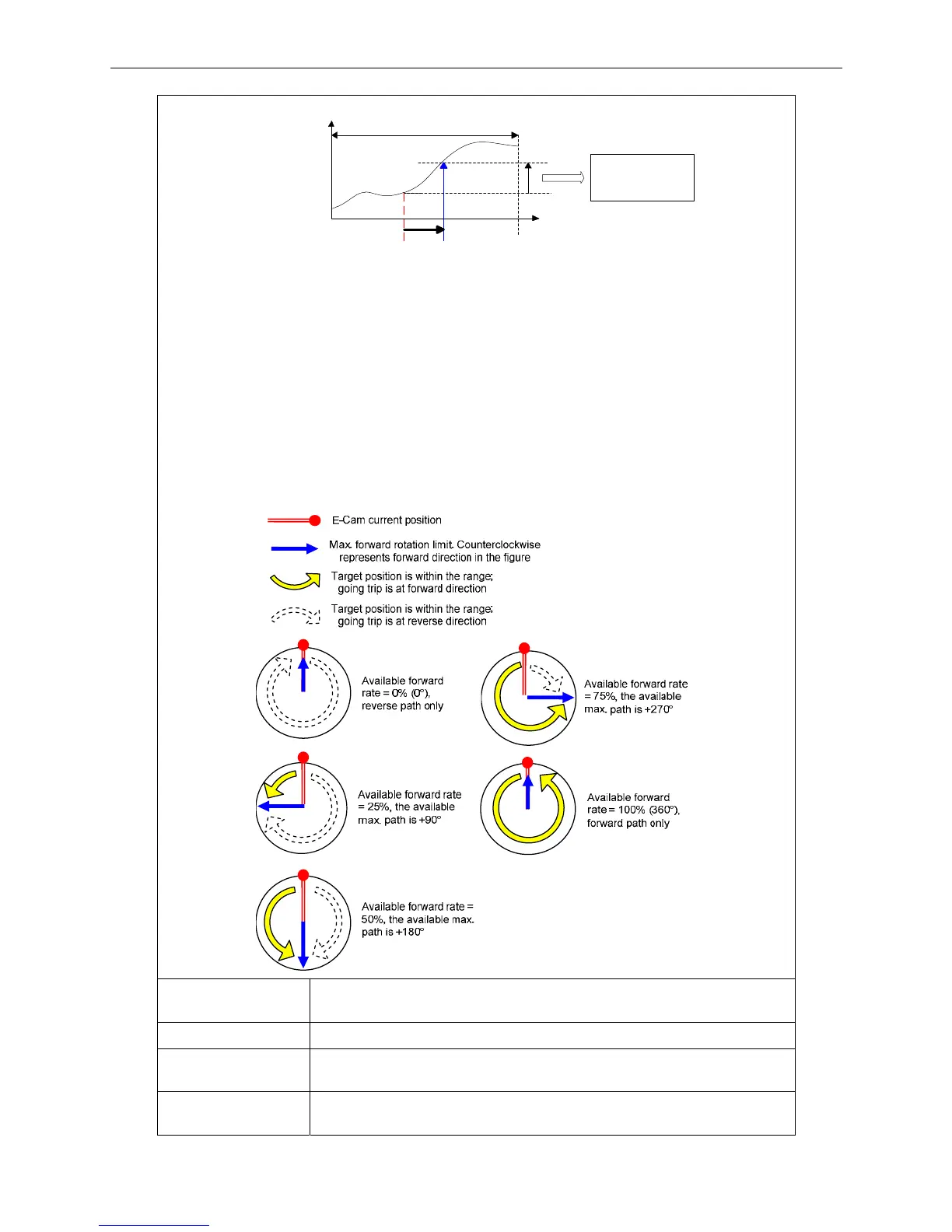

When E-Cam moves from current position to the target one, it can rotate at forward or reverse

direction. Due to the cyclic operation, it can reach the target position either at forward or reverse

direction. However, the moving distance between both is usually different. Use available forward

rate to plan the timing of forward and reverse rotation.

*Available forward rate: The available max. proportion of forward path

Failure code F0E1h When executing this macro, E-Cam is not engaged. E-Cam has to

engage to execute alignment correction.

Failure code F0E2h The setting value of P5-93.YX (PR number) exceeds the range: 0 ~ 0x3F

Failure code F0E3h The setting value of P5-93.UZ (Max. alignment correction rate) exceeds

the range: 0 ~ 0x64 (%)

Failure code F0E4h The setting value of P5-94 (DI delay time compensation) exceeds the

range: -10000 ~ +10000

Loading...

Loading...