ASDA Series Application Note Introduction of E-Cam Operation

March, 2015

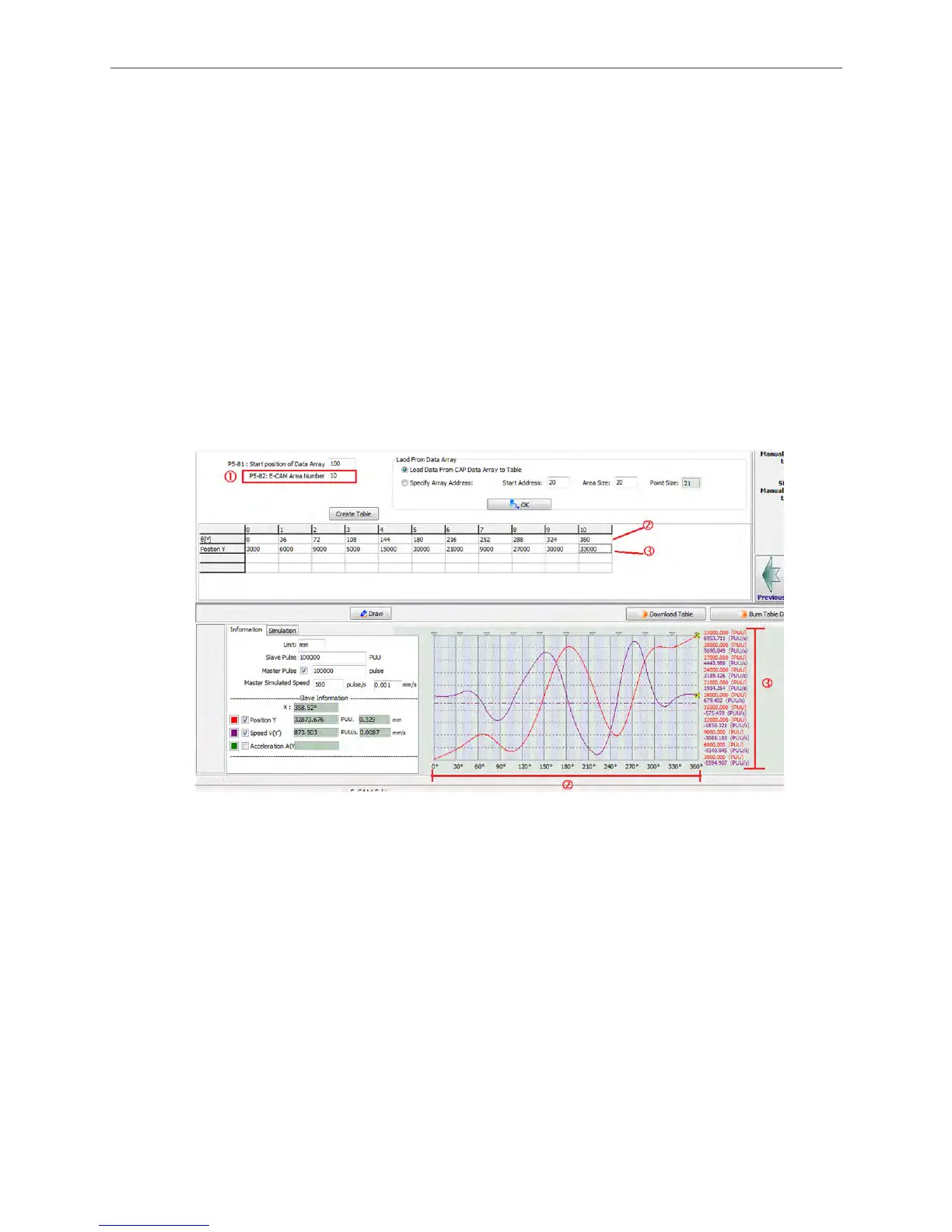

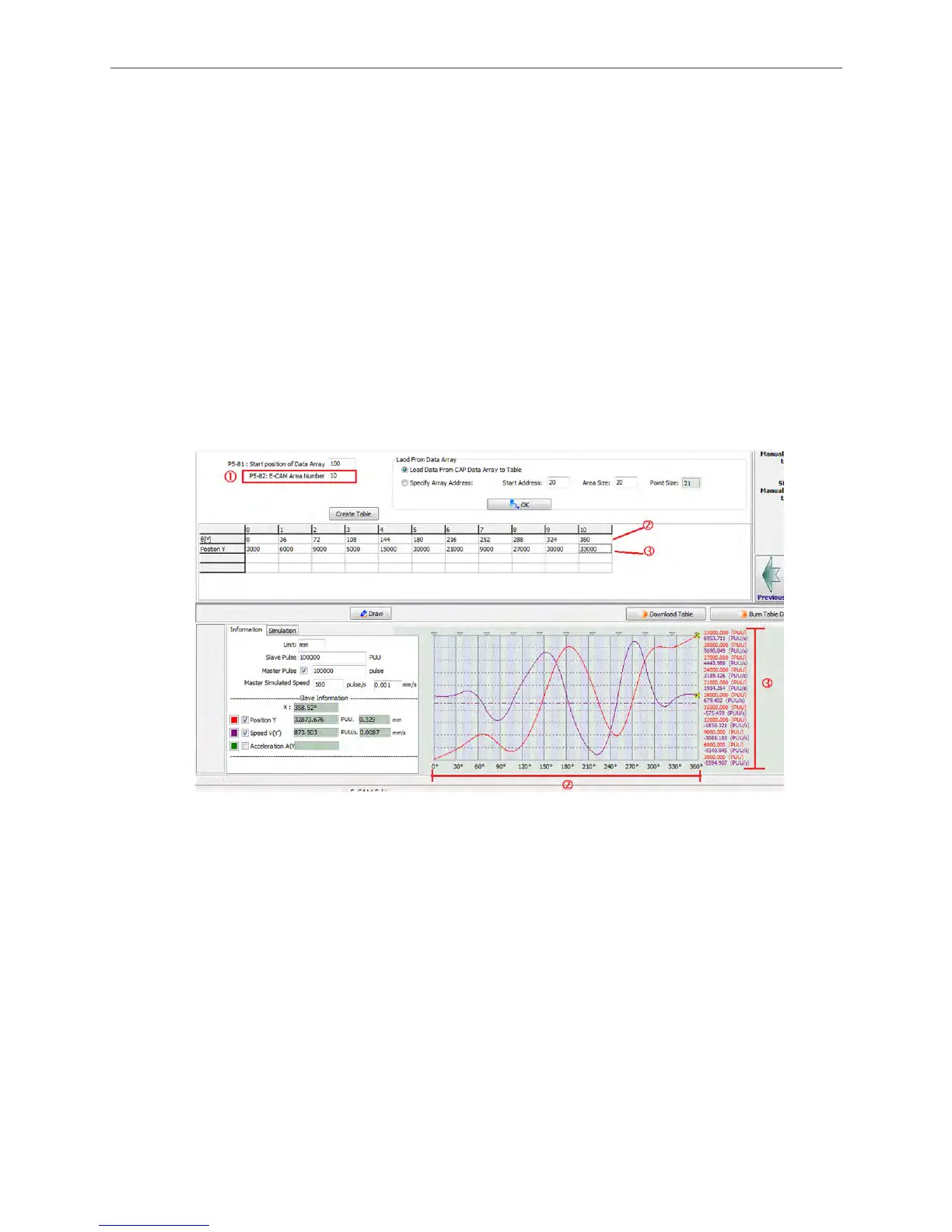

2-17

appropriate area number of E-Cam in data array. Data array is able to store max 800

data. Users need to pay special attention to the setting limit if desire to store multiple

E-Cam curves.

2. After setting up the area number, click on Create Table. Then the software will equally

divide 360 degree equally and put the values into the table according to the area number

set by the user. When E-Cam area number is n, n+ 1 divisions will be shown in the table.

3. Every divided angle that corresponding to a position is put in the table in the unit of PUU.

4. The right down corner of the window will display a complete E-Cam curve. X-axis shows

the angle of E-Cam, from 0° to 360°. Regarding Y-axis, users may select whether to

show position (PUU), speed (PUU/s), or acceleration of the slave axis.

5. When manually creating an E-Cam table, change of position setting should be

reasonable; otherwise, motor overload may occur due to the abrupt speed change or

overcurrent.

Figure 2.22 Manually Create a Table

Speed Fitting Creation

If operating speed becomes users’ first priority when using E-Cam, using Speed Fitting

Creation to create E-Cam curve is recommended.

Figure 2.23 shows the settings of Speed Fitting Creation:

1. Arrange areas according to their proportion in one cycle of E-Cam curve, which includes

waiting area, acceleration area, deceleration area, and stop area.

2. Destination (L) is the total distance the slave axis travels. Its unit is PUU.

3. S-Curve No. is for specifying the smooth level when the position curve transits. The

higher the number the value is, the smoother of motor operation will be during

acceleration and deceleration. Point number of Stop Area is suggested to be set to the

same number as the S-Curve No.

Loading...

Loading...