Introduction of E-Cam Operation ASDA Series Application Note

2-18 March, 2015

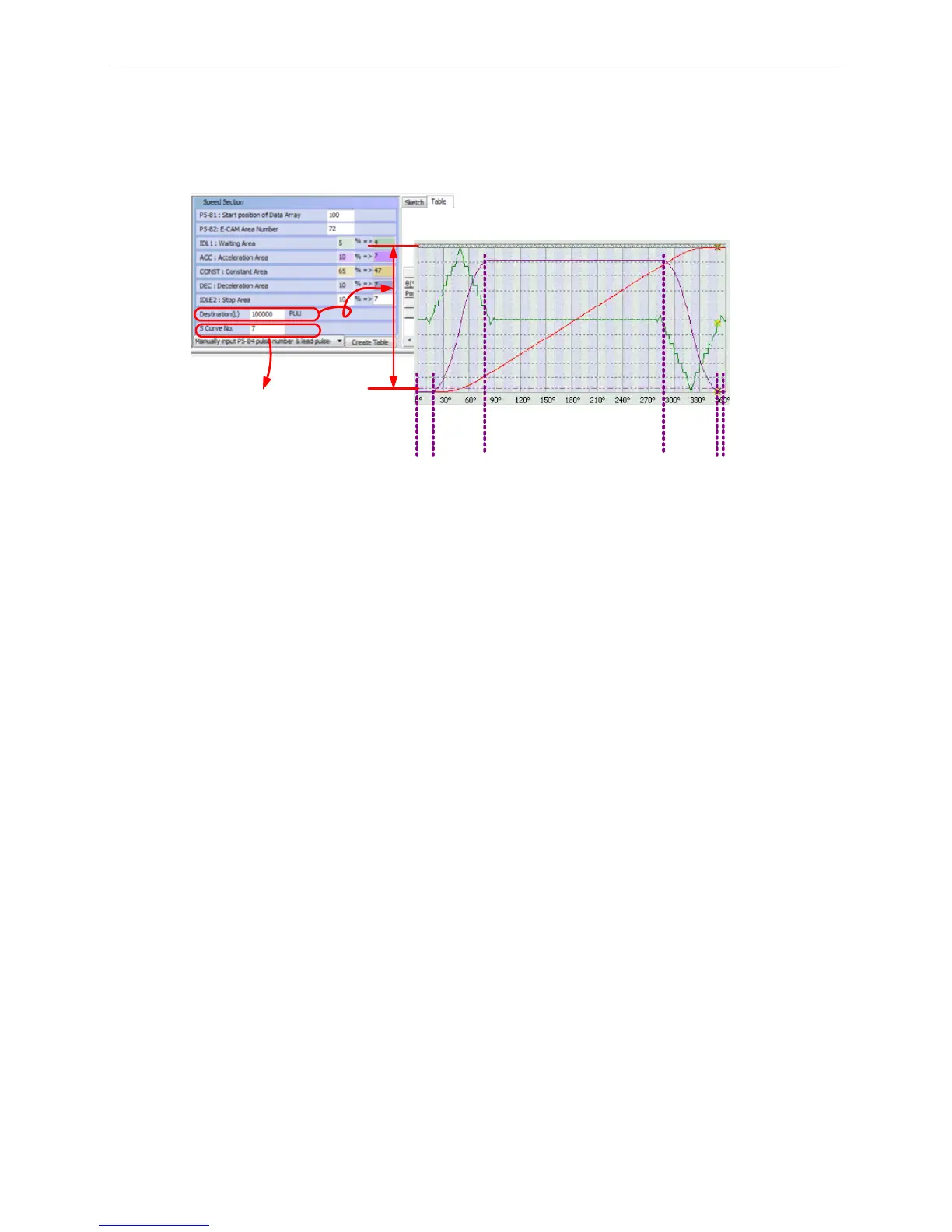

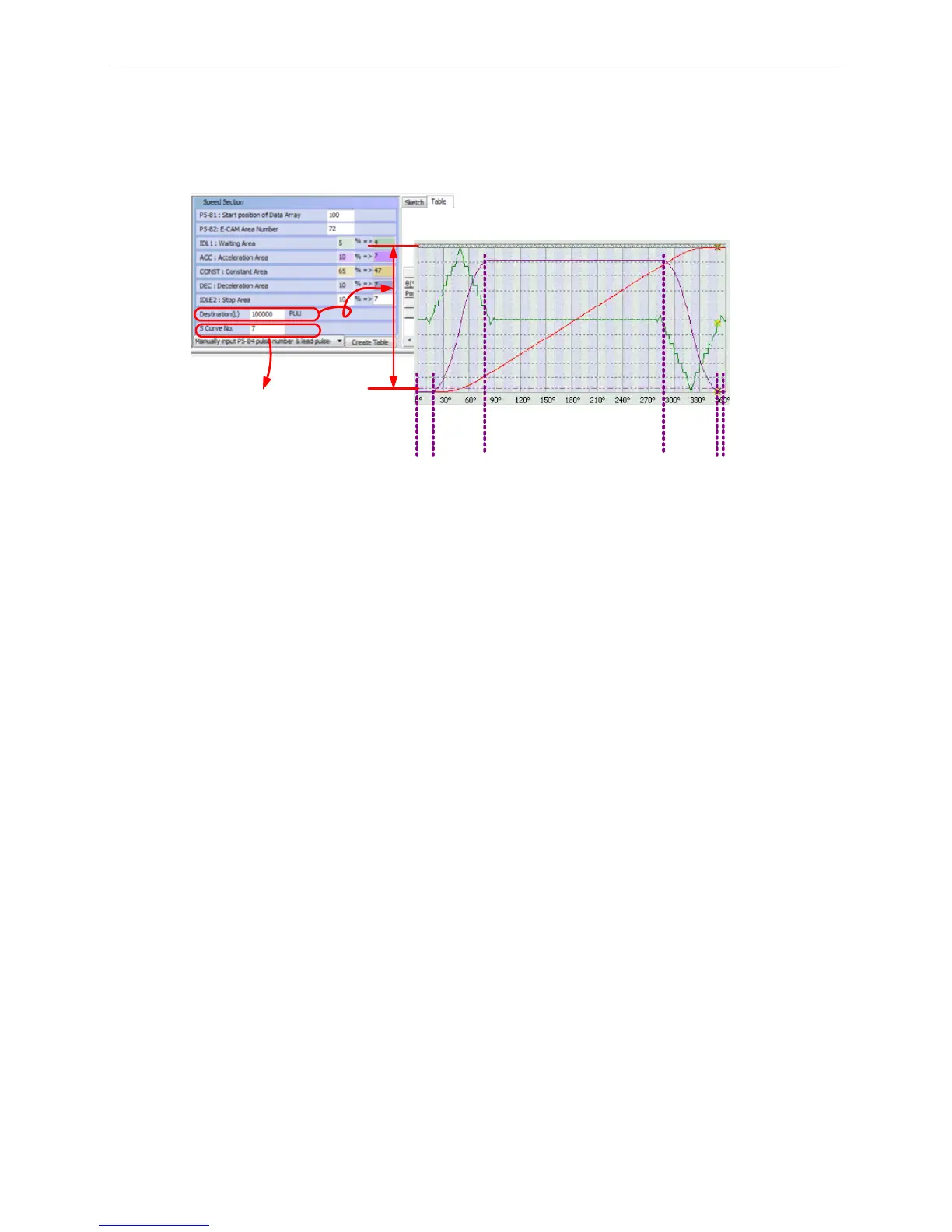

4. Although this method is to use the speed relation to create an E-Cam curve, the system

is actually making a curve by using cam angles and their corresponding position on the

slave axis that are saved in the table.

Figure 2.23 Speed Fitting Creation

Rotary Shear- without Sealing Zone

Rotary Shear- with Zone

Rotary Shear- Adjustable Sealing Zone

Three types of rotary shear curve are available in ASDA-Soft, Rotary Shear-W/O Sealing

Zone, Rotary Shear- W/T Zone, and Rotary Shear- Adjustable Sealing Zone. When using

Rotary Shear-W/O Sealing Zone, the curve created does not have a sealing zone. While

using Rotary Shear-W/T Sealing Zone, a rotary shear curve with fixed 51° in the sealing

zone can be created. When using Rotary Shear-Adjustable Sealing Zone, the width of

constant speed area on the rotary shear curve can be specified by software.

These three ways of creating the table is specifically designed for rotary shear application.

The main difference among them is the setting of constant speed area. In general, a curve

without constant speed area is applied to sharp cutter applications; a curve with constant

speed area is suitable for flat cutter applications. Figure 2.24 presents the basic mechanism

of rotary shear. The master axis is the material feeding axis and the slave axis is the cutter

axis. The key point of rotary shear curve is that the material feeding axis (Master) and the

cutter axis (Slave) must operate at the same speed during the cutting process (when cutter

meets the material) so that the material will not be stocked in front of the cutter or be pulled

by the cutter. See Figure 2.25.

Position

Curve

速度

Constant

Speed area

Smooth level of

the curve

Speed

Curve

Acceleratio

Loading...

Loading...