ASDA Series Application Note Introduction of E-Cam Operation

March, 2015 2-19

Slave Axis

Master Axis

Figure 2.24 Rotary Shear

Material being sent too fast

Material being sent too slow

Figure 2.25 Speed of Master Axis does not Synchronize with the Slave Axis

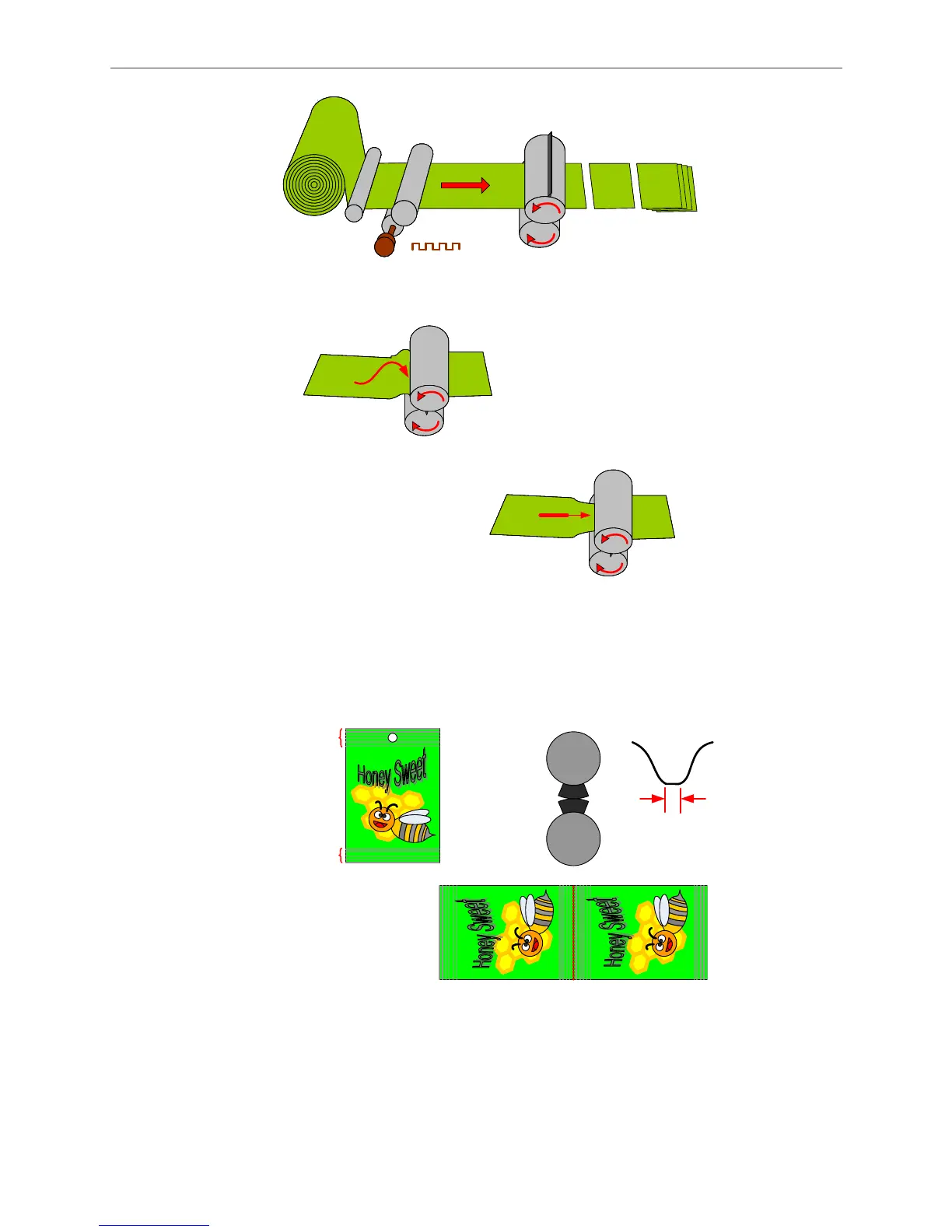

E-Cam curve with a constant speed area is mainly applied to mechanism with flat cutters,

which is generally used for package with sealing zones. See Figure 2.26.

Sealing

Zone

Sealing

Zone

Sealing

Zone

Figure 2.26 Application of Flat Cutter

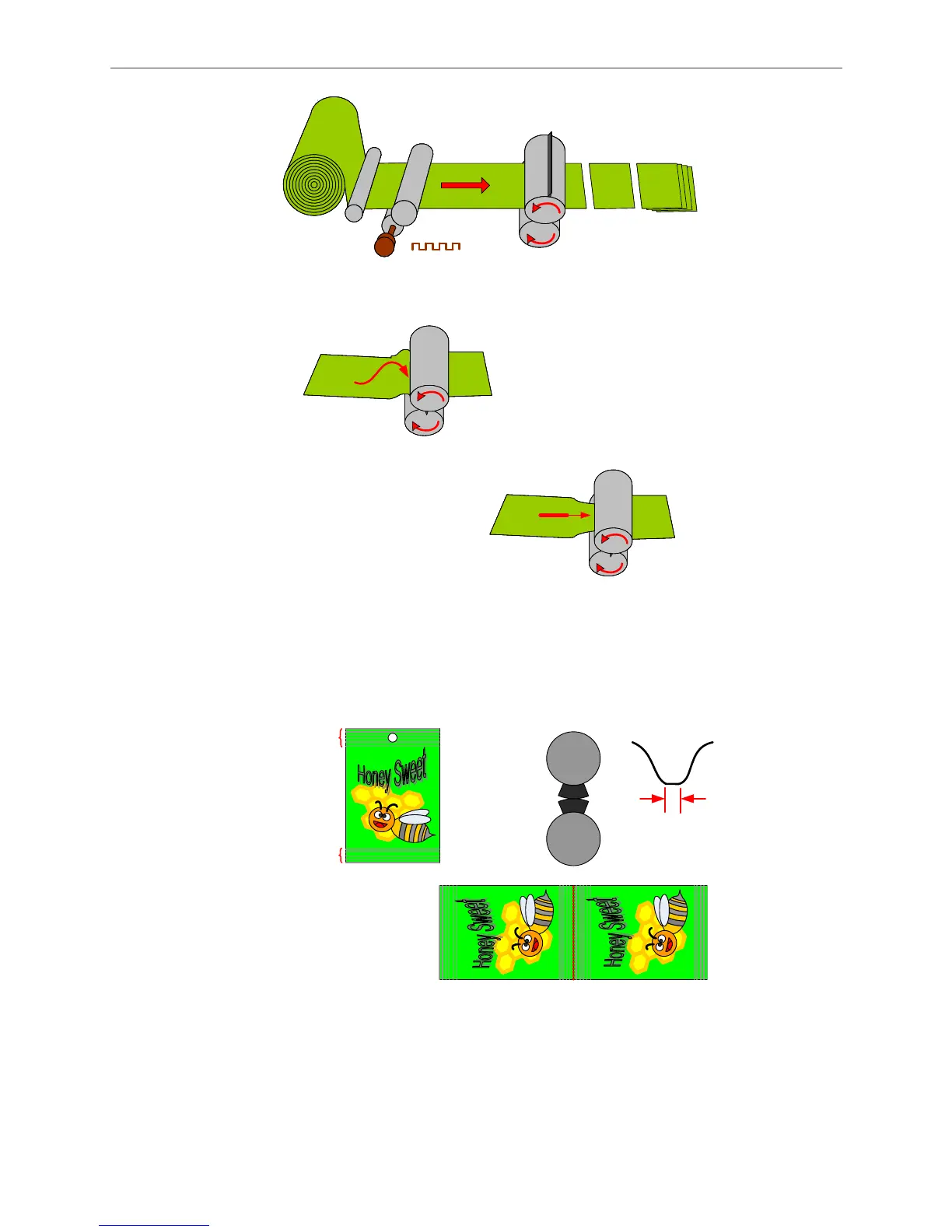

An E-Cam curve with constant speed area will ensure a smooth cutting process without

damaging the material. Figure 2.27 can explain why flat cutters need a constant speed area.

The key is that the master axis and the cutter axis must operate at the same speed during

cutting time. Therefore, as long as the cutting moment is within the constant speed area, a

Loading...

Loading...