Introduction of E-Cam Operation ASDA Series Application Note

2-22 March, 2015

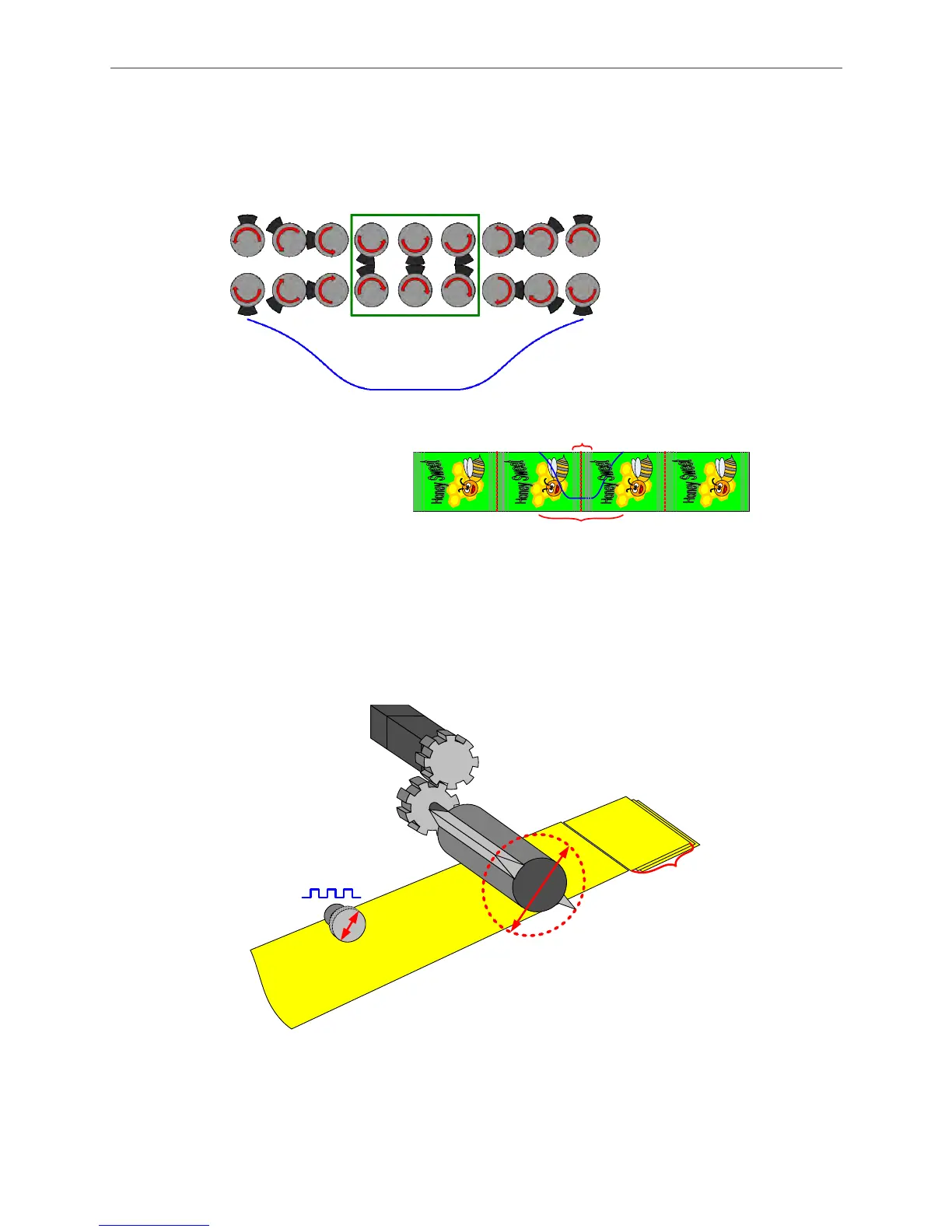

The definition of constant speed area is determined by the proportion of required constant speed

during material feeding, not the constant speed area generated when cutter is operating.

Different material requires different constant speed area. Thus, to generate different E-Cam

curve is required. That is, the constant speed area is determined by the material.

?

º

Constant

Speed Area

360

o

Constant Speed Area

(One Cycle of Curve)

Figure 2.30 Definition of Constant Speed Area

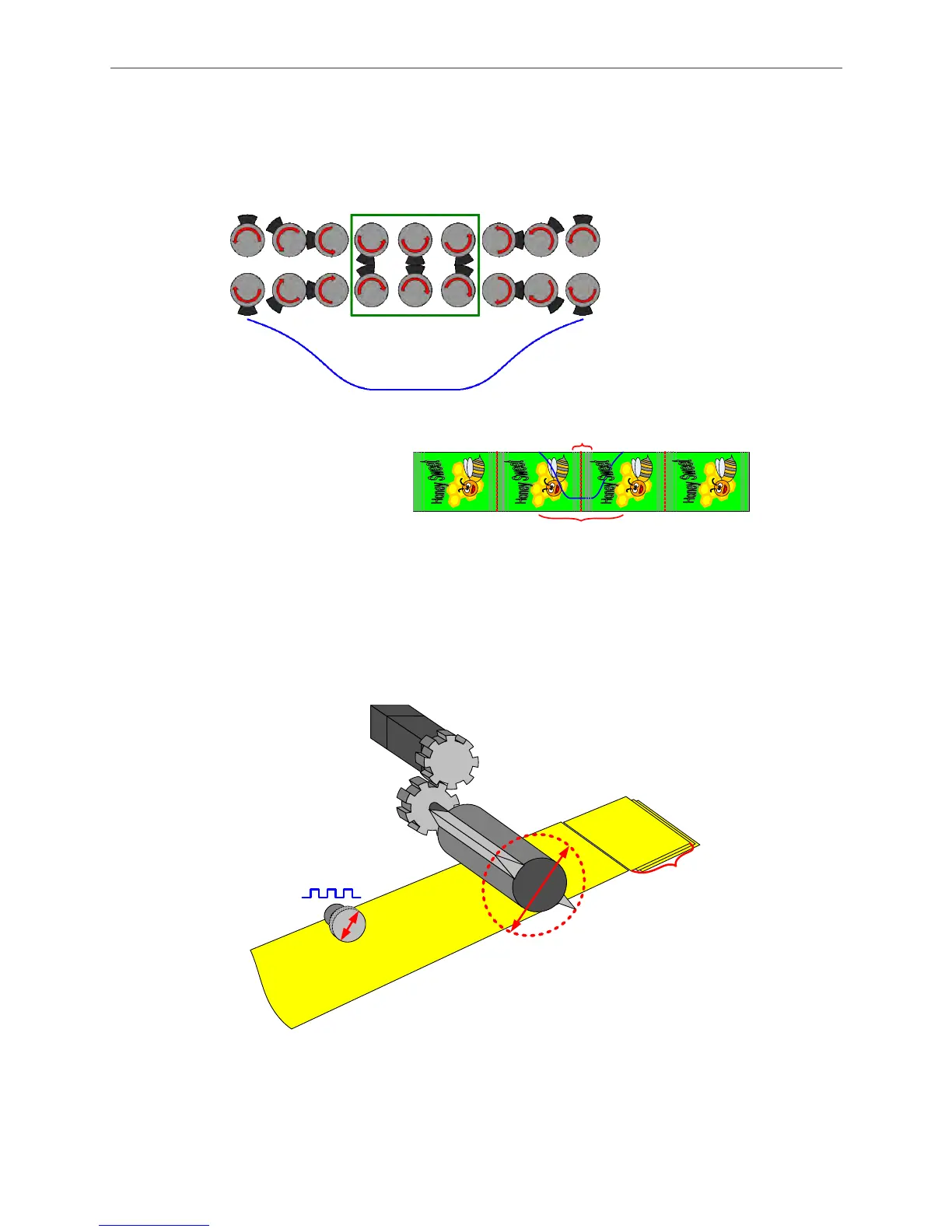

When using software to create an E-Cam curve, the first step is to know the specifications of the

mechanism. Figure 2.31 shows the specifications that users need to know before creating the

curve.

Gear Box

Tooth #A

(to motor)

Tooth #B

(to cutter)

Cutting

Length L

Diameter

d1

Diameter

d2

Encoder pulse

number per

revolution

The

number

of cutter

Figure 2.31 The Mechanism of a Rotary Shear

No matter it is Rotary Shear-W/O Sealing Zone, Rotary Shear- W/T Sealing Zone, or Rotary

Shear- Adjustable Sealing Zone, mechanical specifications is required when creating a curve

via the software. See Figure 2.32.

Loading...

Loading...