ASDA Series Application Note Introduction of E-Cam Operation

March, 2015

2-23

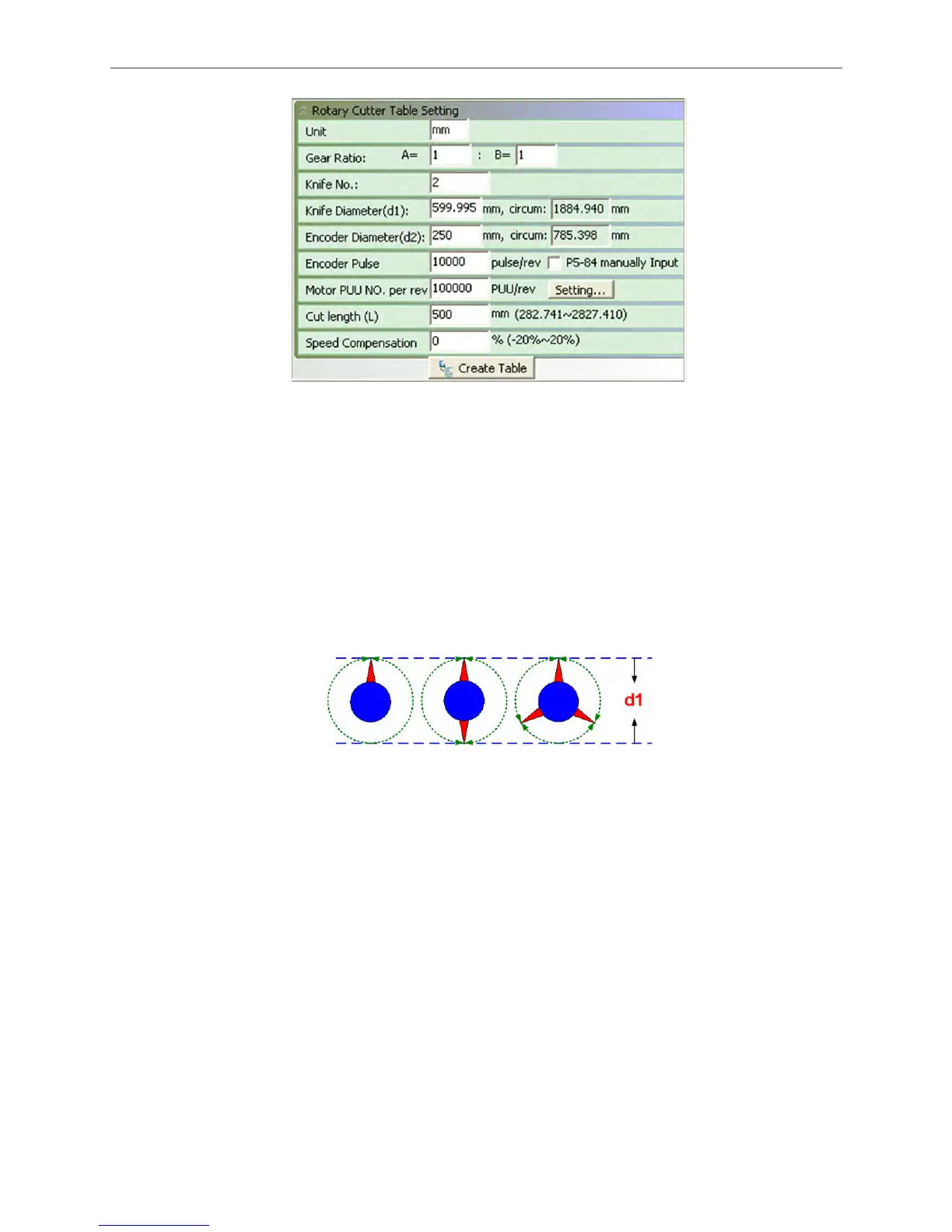

Figure 2.32 Enter Values of Rotary Shear Specifications

Gear Ratio: Directly enter the number of gear and the system will figure out the gear

ratio automatically.

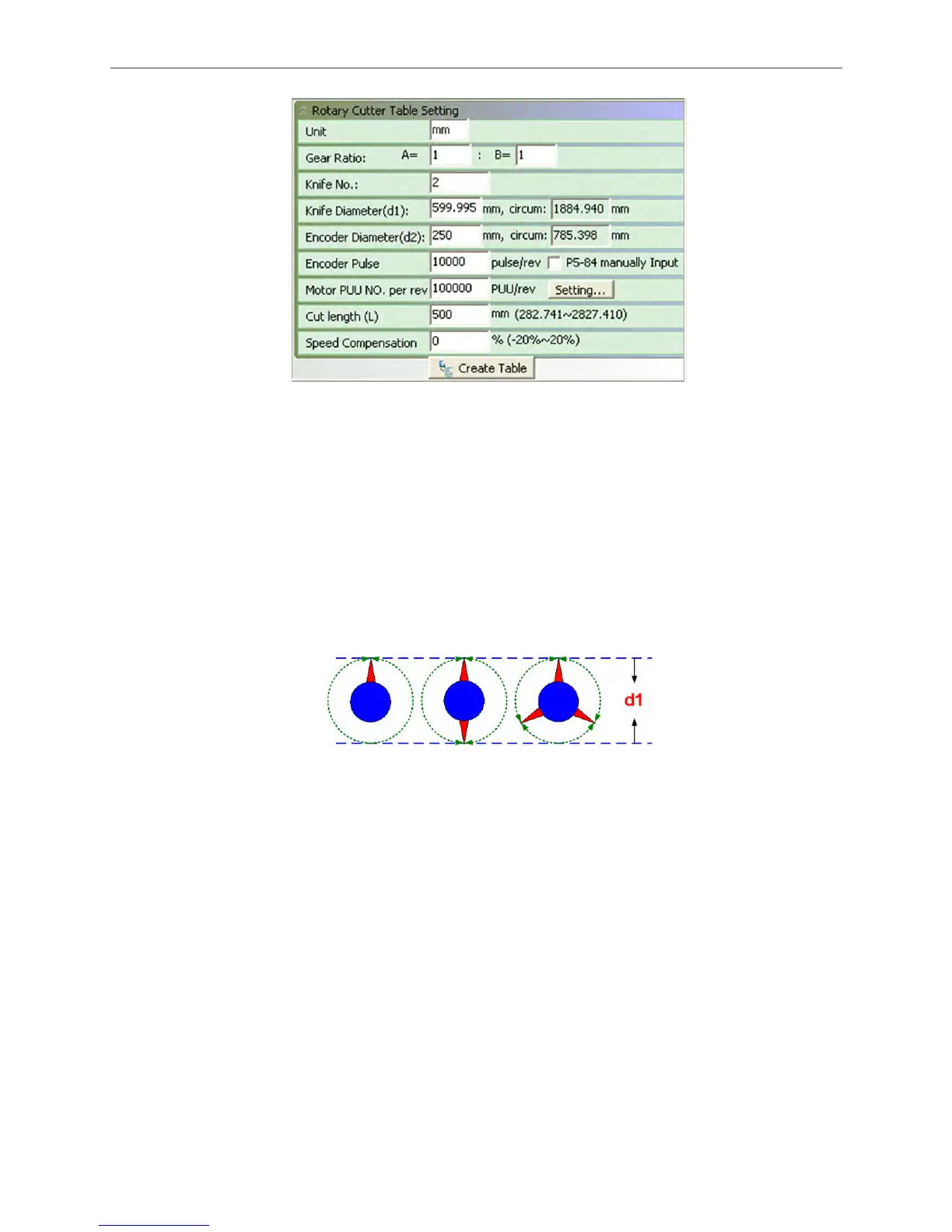

Cutter number (Knife No.) and diameter (Knife Diameter d1): The cutter number can be

changed according to the application and should be equally allocated on the cutter

axis.“Cutter radius” is the distance from cam center to cutter tip, cutter radius times two

is “Cutter diameter”. Therefore, regardless the cutter number, cutter diameter is always

the same. See Figure 2.33. ASDA-Soft will figure out the cutter circumference from the

cutter diameter.

Figure 2.33 The Relationship between Cutter Number and Cutter Diameter

Encoder diameter (d2) and pulse number (Encoder Pulse): Encoder pulse is the pulse

number being sent when encoder rotates one cycle. As encoder diameter and pulse

number are known, the resolution of the command of the master axis can be figured

out, which is the value of P5-84 (when P5-38 = 1). In this case, if pulse number of the

master axis (P5-84) is known, there is no need to enter encoder diameter and encoder

pulse number. Users can directly enter the value of P5-84.

Motor PUU No. per rev.: It is the required PUU when the motor operates one cycle and

converted from E-gear ratio.

Cut length (L): the cutting length of the material, which can be changed by users.

When using the software to create a rotary shear curve, to avoid creating an inappropriate

curve, the software will automatically generate a creatable range based on the ratio of

cutting range and cutter circumference. For example, if cutting length A is much shorter than

Loading...

Loading...