9 Electrical CAM

DVP-PM Application Manual

9-28

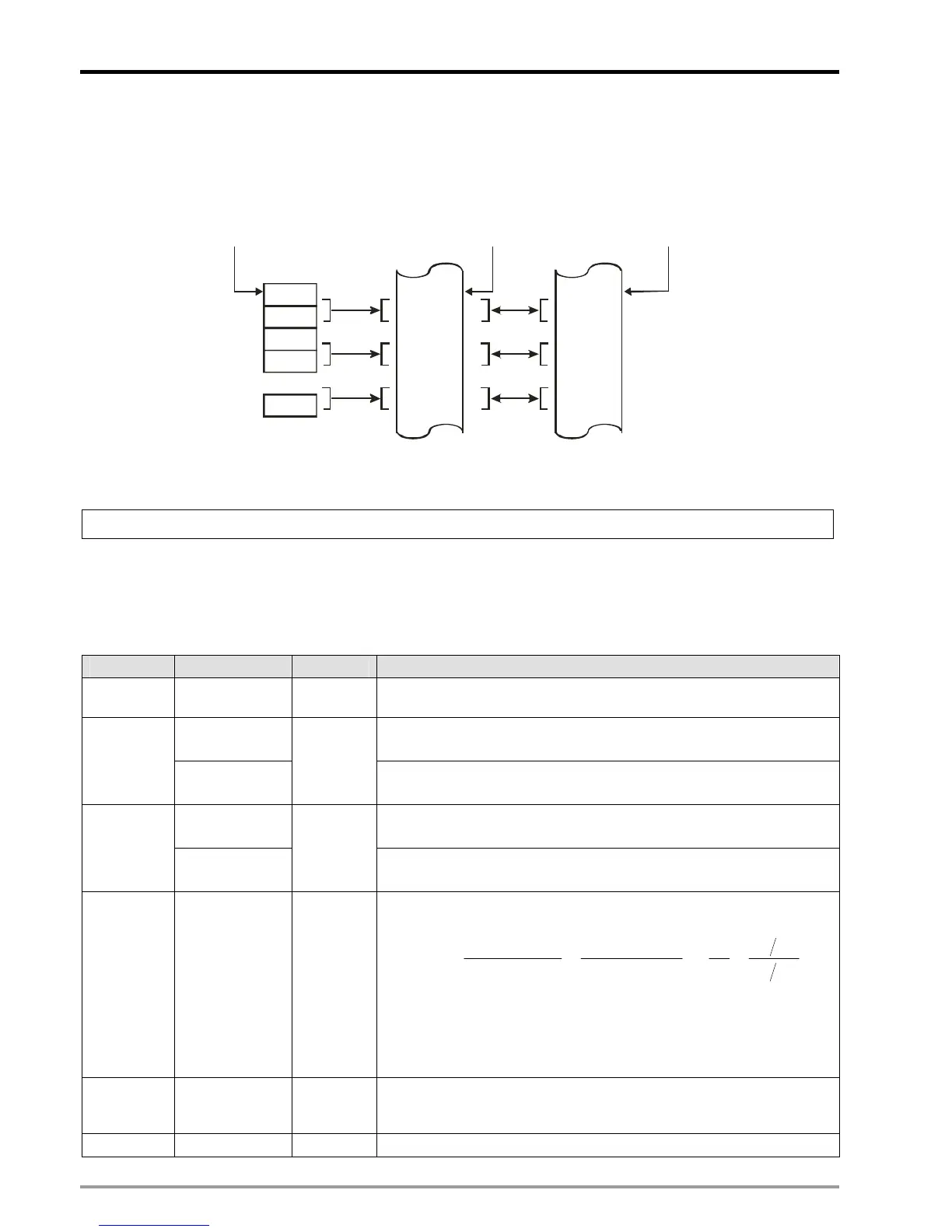

E-CAM data of 10,000 points and is set up by CR#0~9999. One set of E-CAM data consists of 2 points including

Master and Slave position, and the unit of every point is Dword. For example, 2 sets of E-CAM data include 4

Master/Slave points which requires 8 CRs as the below structure. In addition, for details about single-data real

time modification, please refer to 9.4.2.1.

D0

D1

D2

D3

...

D7

CR #0

CR #1

CR #2

CR #3

...

CR #7

M: Master position

S: Slave position

32 -bit instruction n=4 indicates 2 sets of CAM Data,

Specified CR

M0Low

M0High

S0Low

S0High

...

S1High

Corresponding

CAM Data

Specified devices

CR#10000: Create rotary cut E-CAM Data

[Explanations]

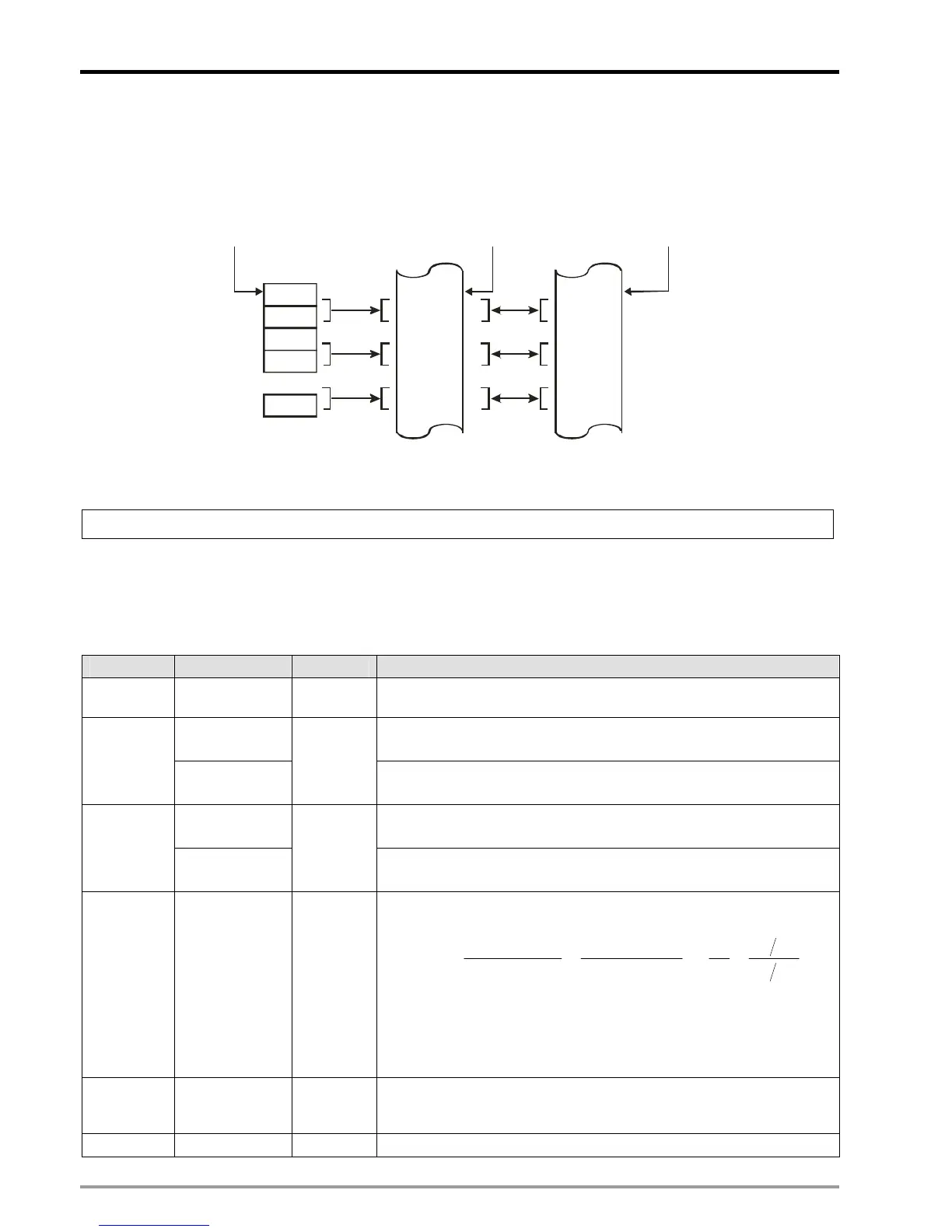

DVP-20PM provides CR#10000 exclusively for creating rotary cut E-CAM. The user can create and apply the

rotary-cut E-CAM by setting up the related machinery parameters according to actual needs. Parameters for

rotary-cut E-CAM are as below:

Parameters Data Format Explanations

P1

Length of

Master

Integer Length of the material feeding axis. Unit:mm

Length of Slave Length of the cutting axis (cutter length included). Unit: mm.

P2

Sync start

position

Integer

When sync function is enabled, the register sets up the sync start

position.

Length of sync

area

Length of sync area. Unit: mm.

P3

Sync end

position

Integer

When sync function is enabled, the register sets up the sync end

position.

P4

Magnification

ratio

Floating

point

The speed of master and slave is synchonized in sync area.

Calculation method of magnification ratio:

11

22

1

2

2

22

1

11

21

14.314.3

DR

DR

F

F

R

DF

R

DF

VV =⇒

××

=

××

⇒=

where,

V

1

(V

2

) = Master(Slave) speed (

mm

/

sec

);

F

1

(F

2

) = Master(Slave) frequency (Hz);

D

1

(D

2

) = Master(Slave) diameter;

R

1

(R

2

) = Master(Slave) pulses of single round.

P5

Max

magnification

ratio

Floating

point

P6

Acceleration Integer E-CAM acceleration setting:

Loading...

Loading...