9 Electrical CAM

DVP-PM Application Manual

9-29

curve

(Low word)

0:const speed

1:const Acc

2:SingleHypot

3:Cycloid

CAM curve selection for different sections in sync area, e.g. start,

end:

0: leftCAM: Sync area is on the left side of CAM curve

1: midCAMall: Sync area is in the middle

2: midCAMbegin

3: midCAMend: (When the curve is selected, E-CAM stops

automatically when completed)

5: rightCAM: Sync area is on the right side of CAM curve.

Note: when CAM curve 2 or 3 is selected, the langth of Master will

be calculated by system.

CAM curve

(High word)

Integer

Sync area setting

b[13]=1: Create sync area setting. When the function is enabled, P2

and P3 should be filled with start and end position of sync area.

b[14]=1: Only single data real-time modification is applicable.

b[15]=1: Borrow the data setting of previous E-CAM

P7 Results Integer

Display the rotary cut E-CAM creating results (when read back):

0: OK

1: Input data is not proper

2: Insufficient length of E-CAM.

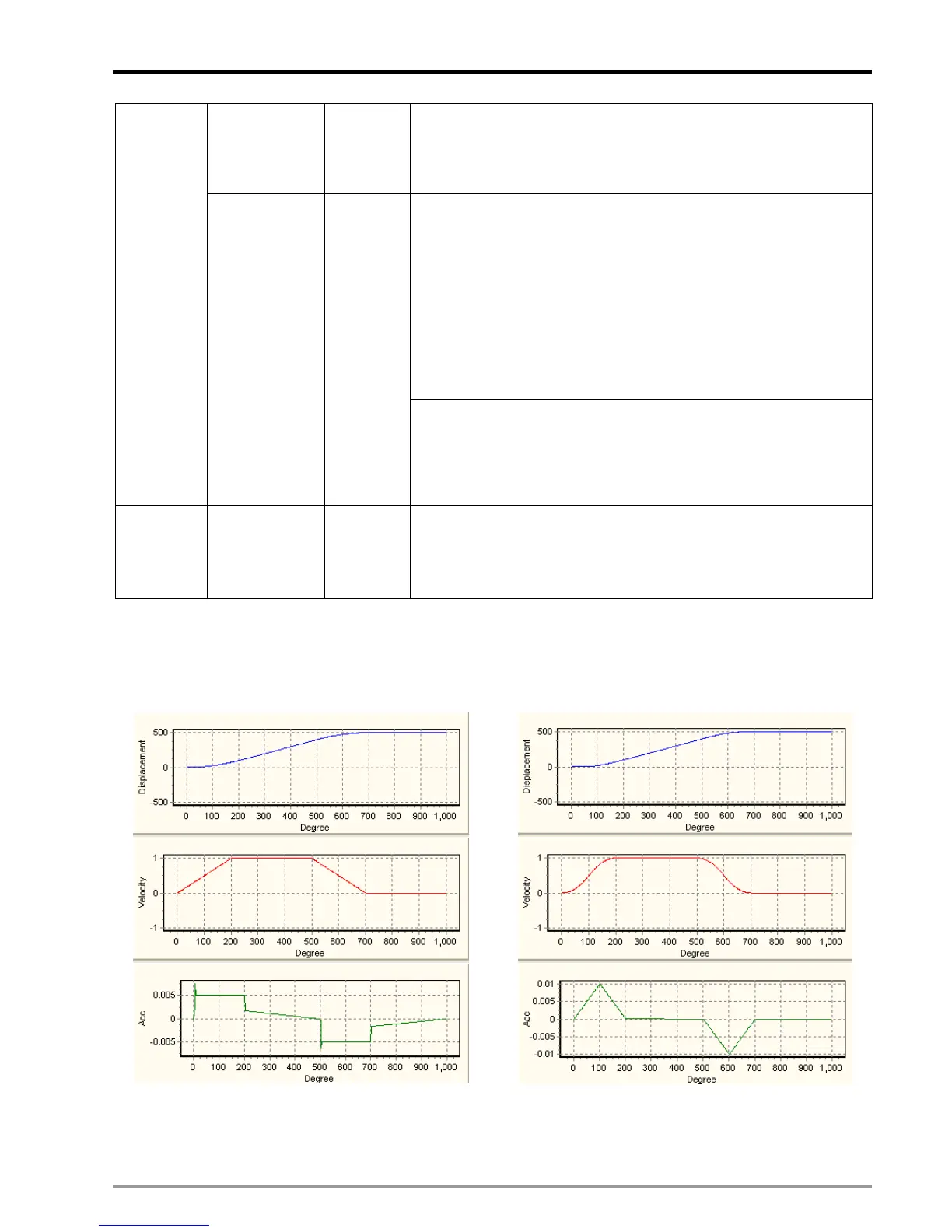

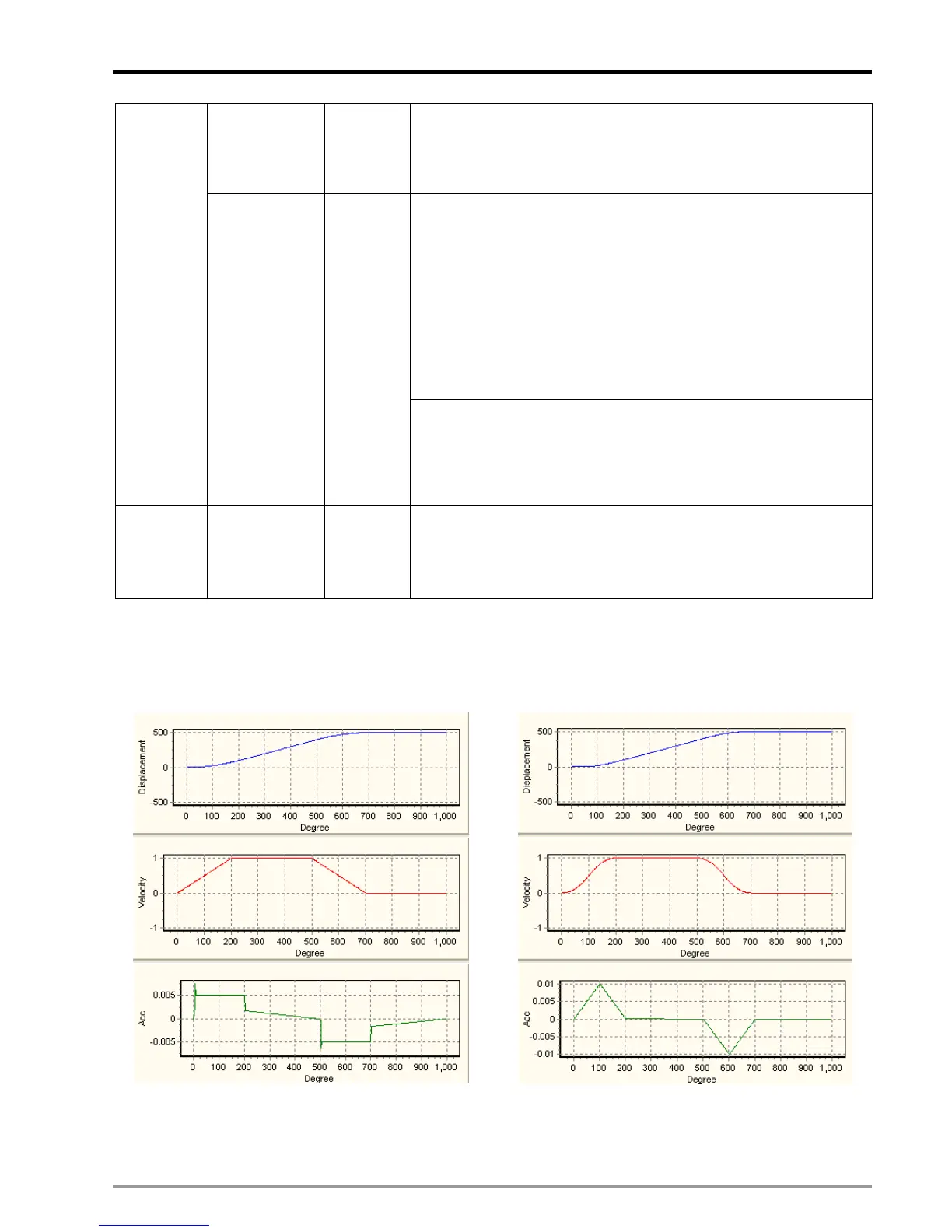

P6 sets up the rotary cut acceleration curves and the E-CAM curves, and the examples of each curve are as

below:

Acceleration curves

0: const speed

1: const Acc

Loading...

Loading...