9 Electrical CAM

DVP-PM Application Manual

9-31

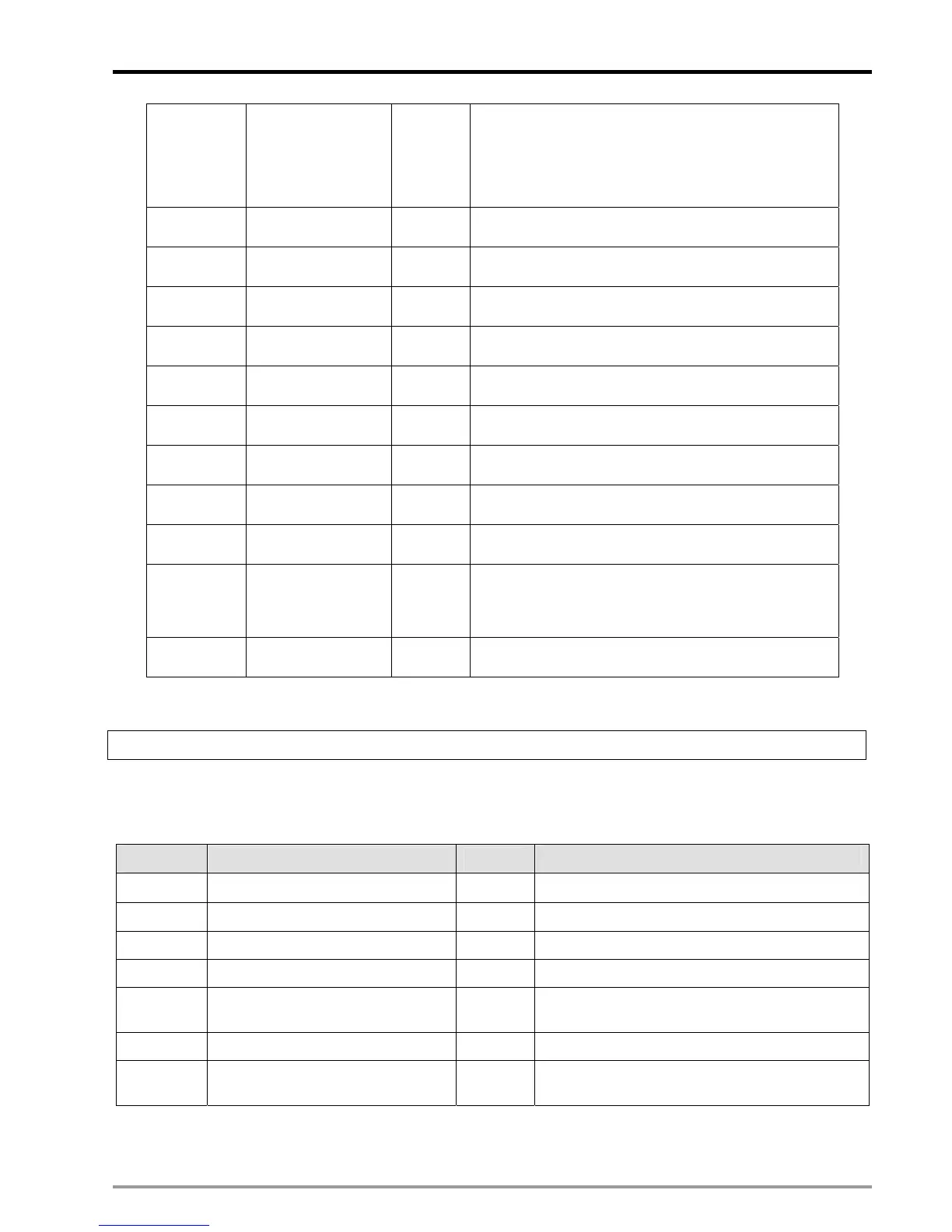

equally divided by the drop times of cutter)

b[2]=1: Specify the number of data points in sync area

b[3]=1: Borrow the data setting of previous E-CAM

b[4]=1: Non-smooth acceleration/deceleration for

fixing the resoulution.

P2

Pulses per round of

Master

Integer Unit: Pulse

P3

Length per round of

Master

Integer Unit: mm

P4

Pulses per round of

Slave

Floating

point

Unit: Pulse

P5

Length per round of

Slave

Floating

point

Unit: mm

P6

Sync start angle of

Slave

Integer Set range: 180~360 degree

P7

Sync end angle of

Slave

Integer Set range: 180~360 degree

P8

Length of cutting

process on Master

Integer Unit: mm

P9

Number of cutters

on Slave

Integer Number of cutters applied in rotary cut application

P10

Length of Master

before sync area

Integer

When P1 is set as 1, the parameter sets the length of

Master before sync area.

P11

Angle between

start position and

sync start: angle θ

1

(degree)

Integer

When P1 is set as 1, the parameter sets the angle

before Sync Start.

P12

Number of data

points in sync area

Integer

When b[2] of P1 is 1, the parameter sets the number

of data points in sync area.

For detailed explanation of creating thick material cutting E-CAM curves, please refer to 9.4.2.4.

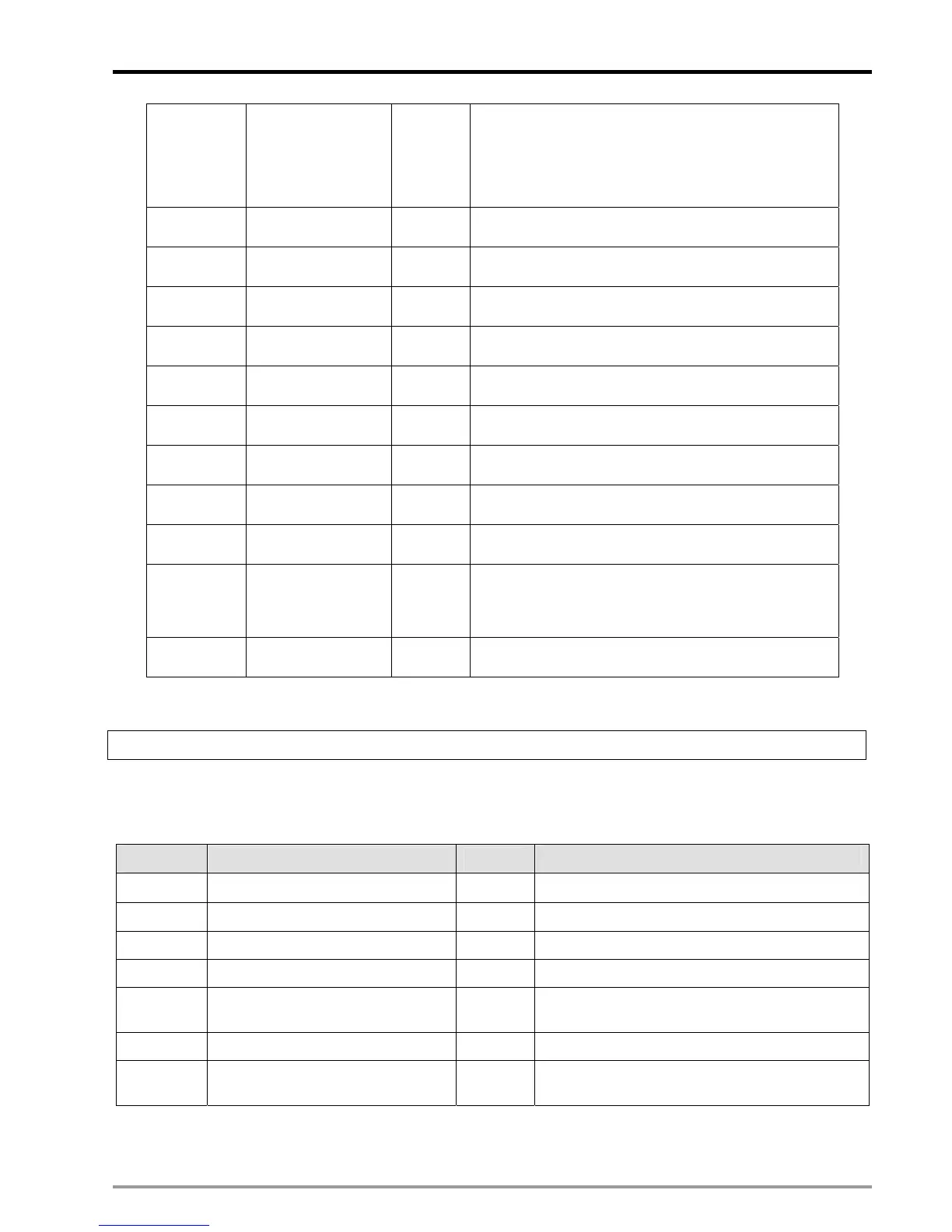

CR#10001:

Read E-CAM status

[Explanations]

The function is used to read current E-CAM status when E-CAM is executing. Only DFROM instruction is

applicable for this function. The read data will be as follows:

Parameters Data Format

Explanations

P1 Current position of Master

Integer

Reset at DOG signal

P2 Length of Master 1 Integer DOG signal to DOG signal

P3 Current E-CAM curve Integer

P4 Current position of Slave Integer Updated at DOG signal

P5 Error of Slave

Integer

Error between DOG signal and the end point of

CAM cycle.

P6 Length of Master 2 Integer START0/PG0 signal to START0/PG0 signal

P7 Error of Master

Integer

Error between START0, PG0 signal and the end

point of CAM cycle

The function of reading E-CAM status can be applied in offset compensation to Slave error. For the methods of

Slave error compensation, please refer to 9.4.2.5.

Loading...

Loading...