9 Electrical CAM

DVP-PM Application Manual

9-52

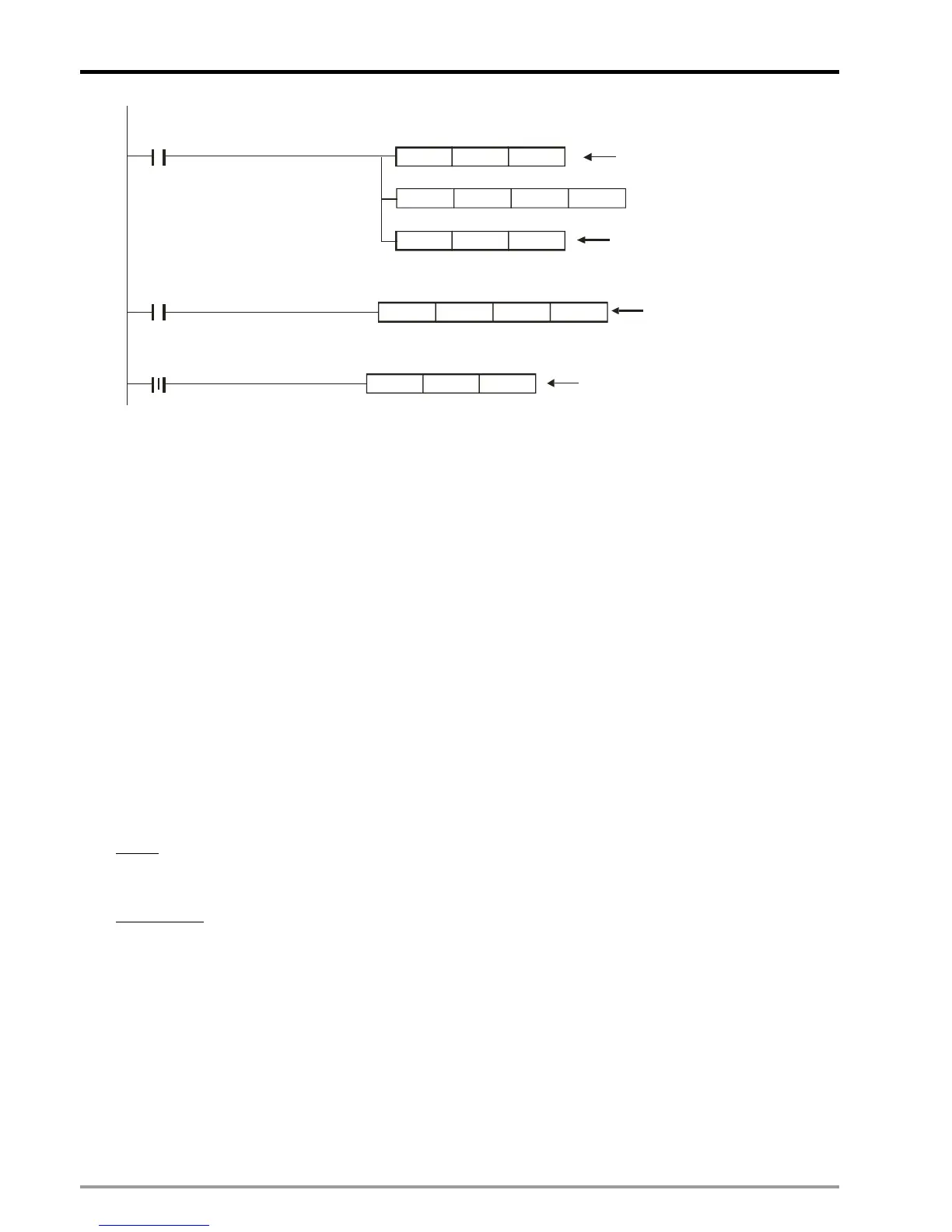

M4

DFLT

D138

D140

M4

M4

..

..

..

DEDIV F2.0 D142

D140

DINT

D142 D144

DSUB

D126

D302

D144

DMOV

D126 D302

Convert the offset value into

floating point value

D142=1/2 D138

Users can decide an

offset ratio

Backup the actual

offset value

Calculate the modified Slave

length according to the actual

offset value

When calculation is finished,

move the length of Slave into

D302

back

Points to note:

1. Users can modify the offset ratio (0.5*D138 ) according to actual needs

2. D132 has to be applied in DTO instruction for creating rotary cut E-CAM Data with offset compensation

in this example

Set up M4 to calculate the actual offset value and the modified Slave length

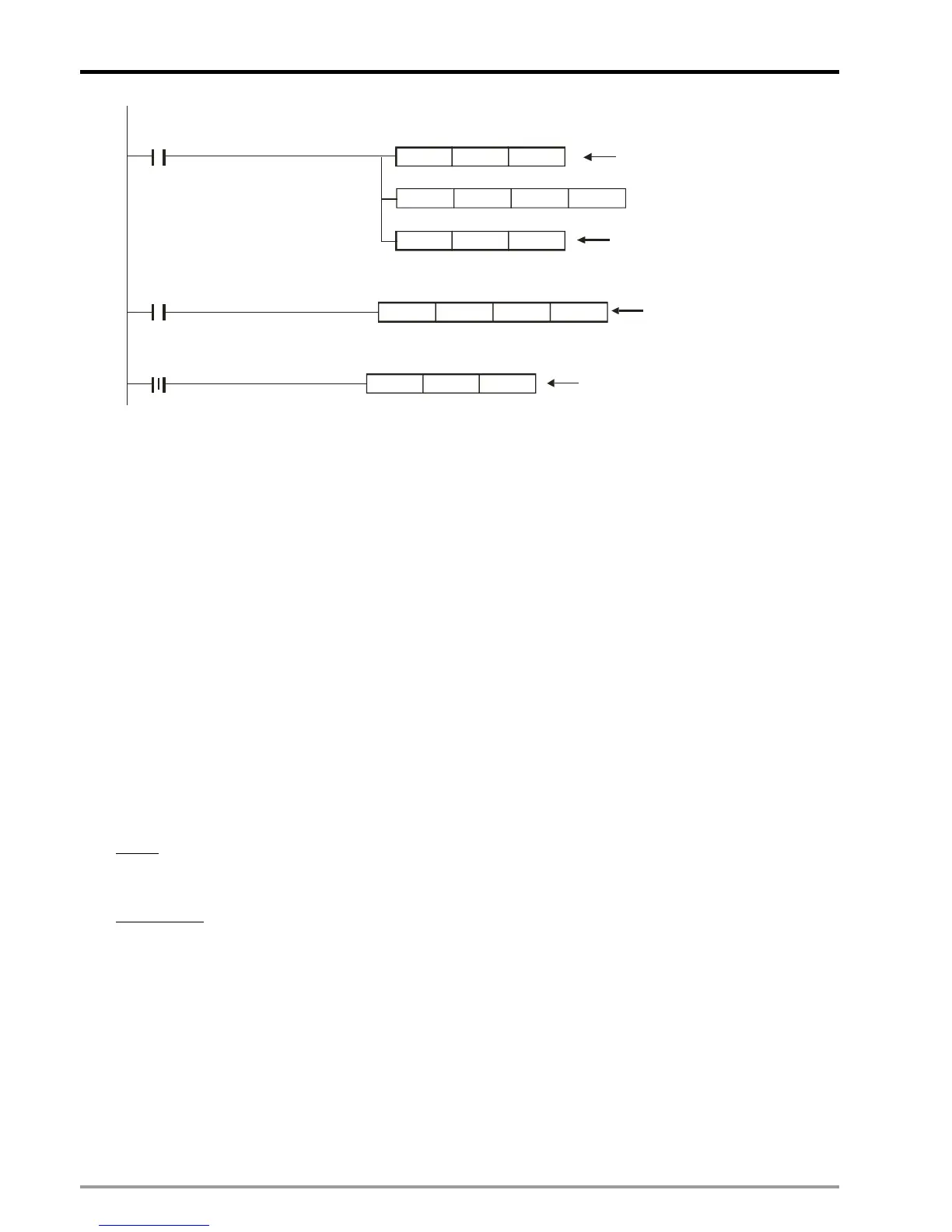

9.4.2.6 Flying Saw Application –Check cutter position

In flying saw application, it is important to check if the cutter is back in designated position when moving

back. If the cutter is not at designated position, it should remain current speed until limit switch is met,

otherwise the mechanical system might be damaged during the moving back process of cutter. M1757 can

be applied to remain current speed of Slave and continue operation until the limit. Users can compare the

designated position with Master position in current cycle to decide if M1757 needs to be enabled. Master

position in current cycle can be obtained by subtracting “Master position captured at the end of cycle” from

accumulated Master position (DD1862). Master position captured at end of cycle can be read out by using

DFROM instruction (D0 = K10005, Capture mode).

Application Example

Set up

:

Check if the cutter position is correct and automatically determine the execution of M1757.

Control Steps

:

Step 1: Run the program and read the E-CAM status in capture mode by DFROM instruction. Read the data

in CR#10005 (Capture mode) of special module K100 to D300~D308 at the end of cycle.

Step 2: Substract the captured Master position (D306) from the

number of accumulated MPG input pulses

(D1862), and we can obtain the actual Master position in current cycle (D350).

Step 3: Compare the actual Master position (D350) with the target position (D1842). If the actual Master

position is bigger than the target position and the limit switch has not been triggered, execute M1757 then

stop the CAM operation.

Loading...

Loading...