9 Electrical CAM

DVP-PM Application Manual

9-51

Step 1: Run the program and read the E-CAM status by DFROM instruction. Read the data in CR#10001 of

special module K100 to D100~D108.

Step 2: Set M3 to write the length of Slave into D126 and the initial Slave error into D128. Calculate the real

error, i.e. difference between the increased error and the initial error, and take the half of Slave length as the

reference.

Step 3: When the real error is between “± half of Slave length”, take the real error as the offset value directly.

Step 4: When the real error exceeds “± half of Slave length”, follow the below rule:

⎪

⎩

⎪

⎨

⎧

×+=⇒−<

×=⇒>

ratio OffsetSlave of lengtherror RealOffsetSlave of length error Real

ratio OffsetSlave of lengtherror RealOffsetSlave of length error Real

)(

2

1

)-(

2

1

Step 5: Set M4 to calculate the modified length of Slave with offset compensation.

Step 6: When M4 is reset, fill the original length of Slave back to D302.

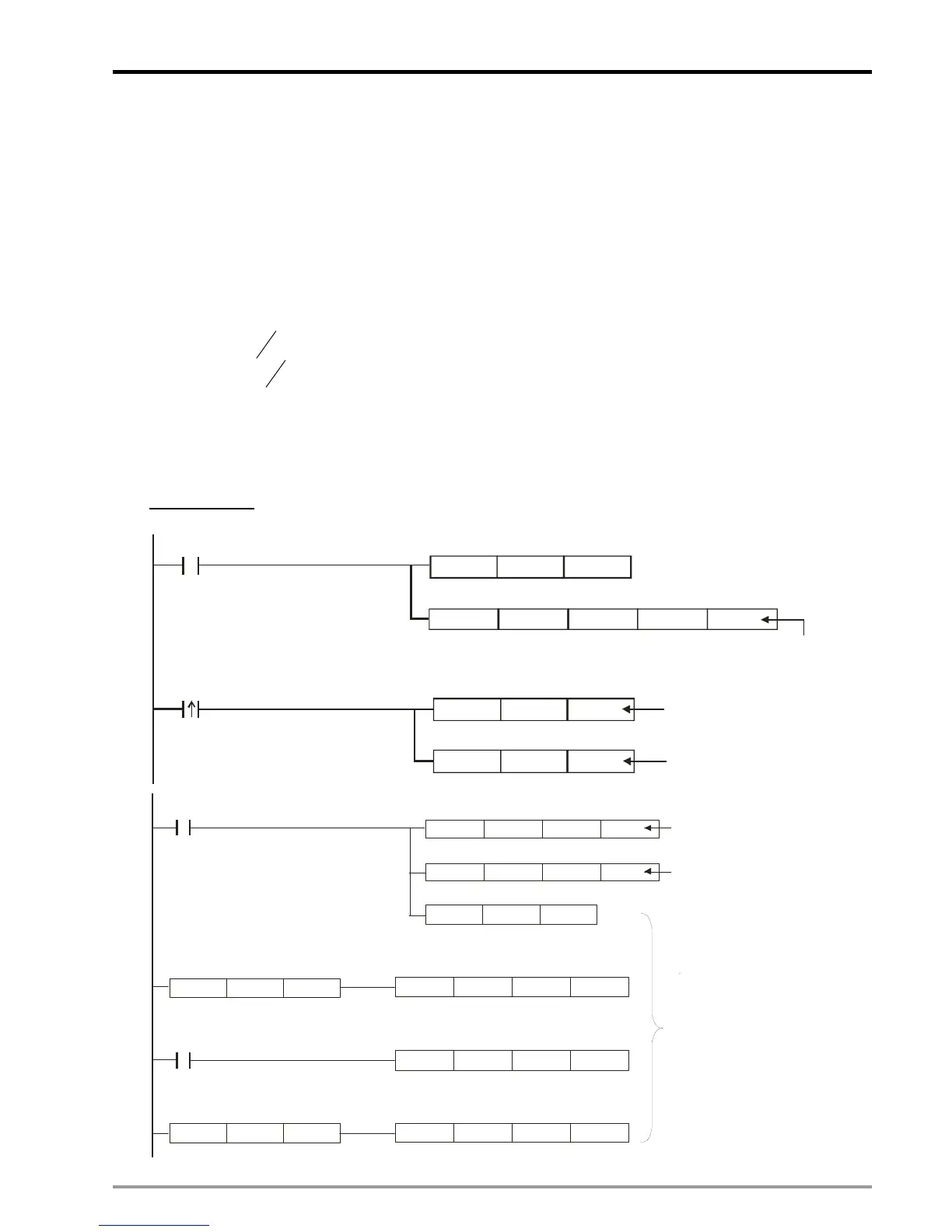

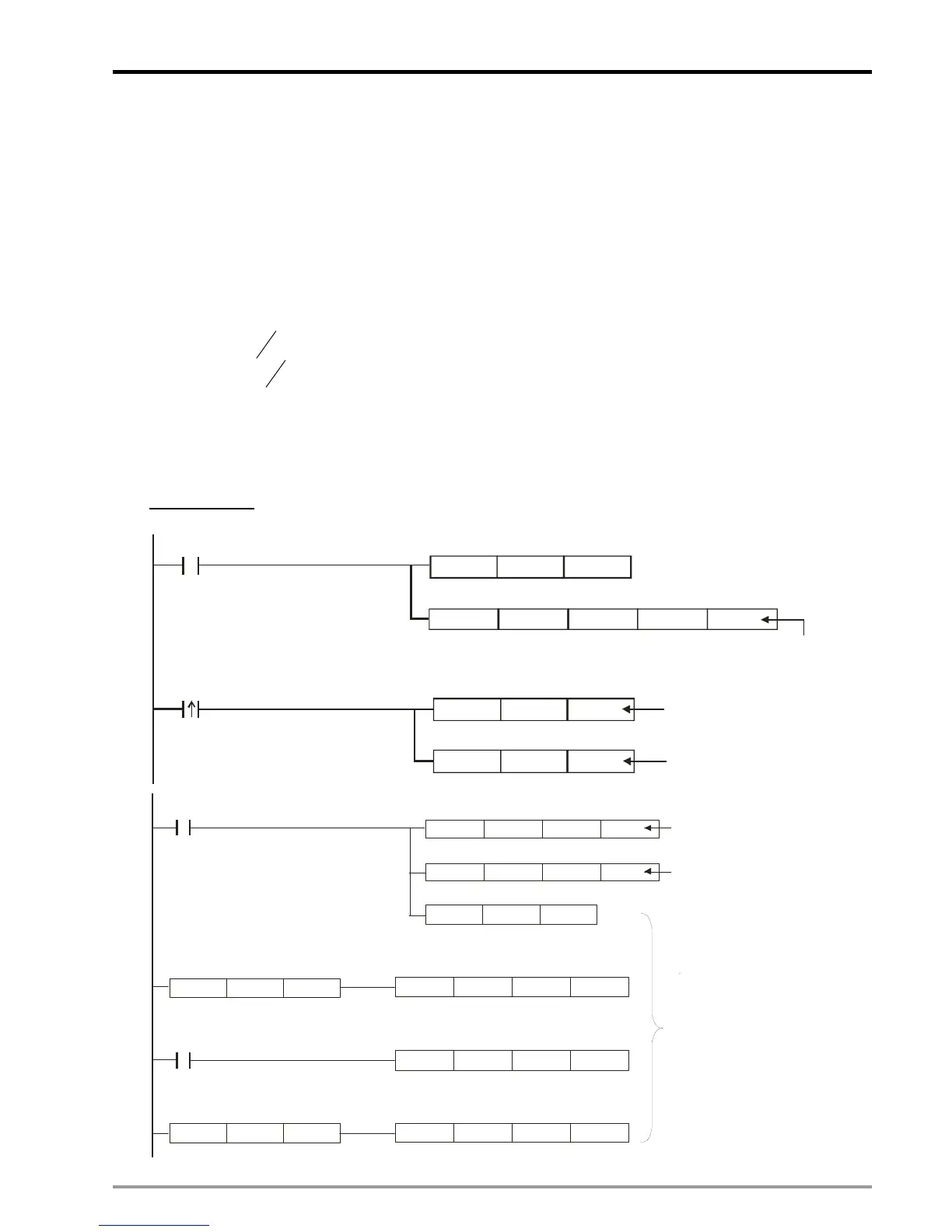

Ladder Diagram

:

M1000

M3

DMOV

K10001 D0

DFROM K100

D0 D100 K5

DMOV D302 D126

D108

D128

DMOV

Backup initial value of D108

Length of Slave

Backup D302

Backup D108 in D128

Read the error between

DOG signal and the end point

of Slave position (D108)

DSUB

D108

D128 D130

DDIV

D126

K2

D132

DMOV

D130 D138

DSUB

D130

D126

D138

DSUB D132

K0 D136

DADD

D130

D126

D138

M1000

M3

"

D132 = 1/2*D126

D136 = -1/2*D126

.

..

..

..

DLD<

D130

D136

DLD>

D130

D132

Take the difference

between D108 (initial error)

and D128 (increased error)

Take D132 and D136

as the criteria for judging

1. If D130 (real error)is between

D132 and D136, backup D130 in

D138 directly

2. If D130 is bigger than D132

,subtract D130 with D126 and

store the result in D138.

3. If D130 smaller than D136

, add D130 with D126 and store

the result in D138

D138 is the offset value for

compensation

Loading...

Loading...