9 Electrical CAM

DVP-PM Application Manual

9-56

Set value of Slave in No.100 and No.201 indicates the target number for next execution. Therefore, before

the switching point is reached users can insert or modify the data in the next section. However, care should

be taken on setting the starting value of the second section. For second section, if the starting value of

Master (M101) is set as 0, Slave will continue the execution based on the ending value of previous section,

i.e. the starting value will be Master position: M99+M102, and Slave position: S99+S101.On the other hand,

if the starting value of Master is not “0”, the starting value of Slave will be based on “0”, i.e. Master position:

M99+M102 and Slave position: 0+S101.

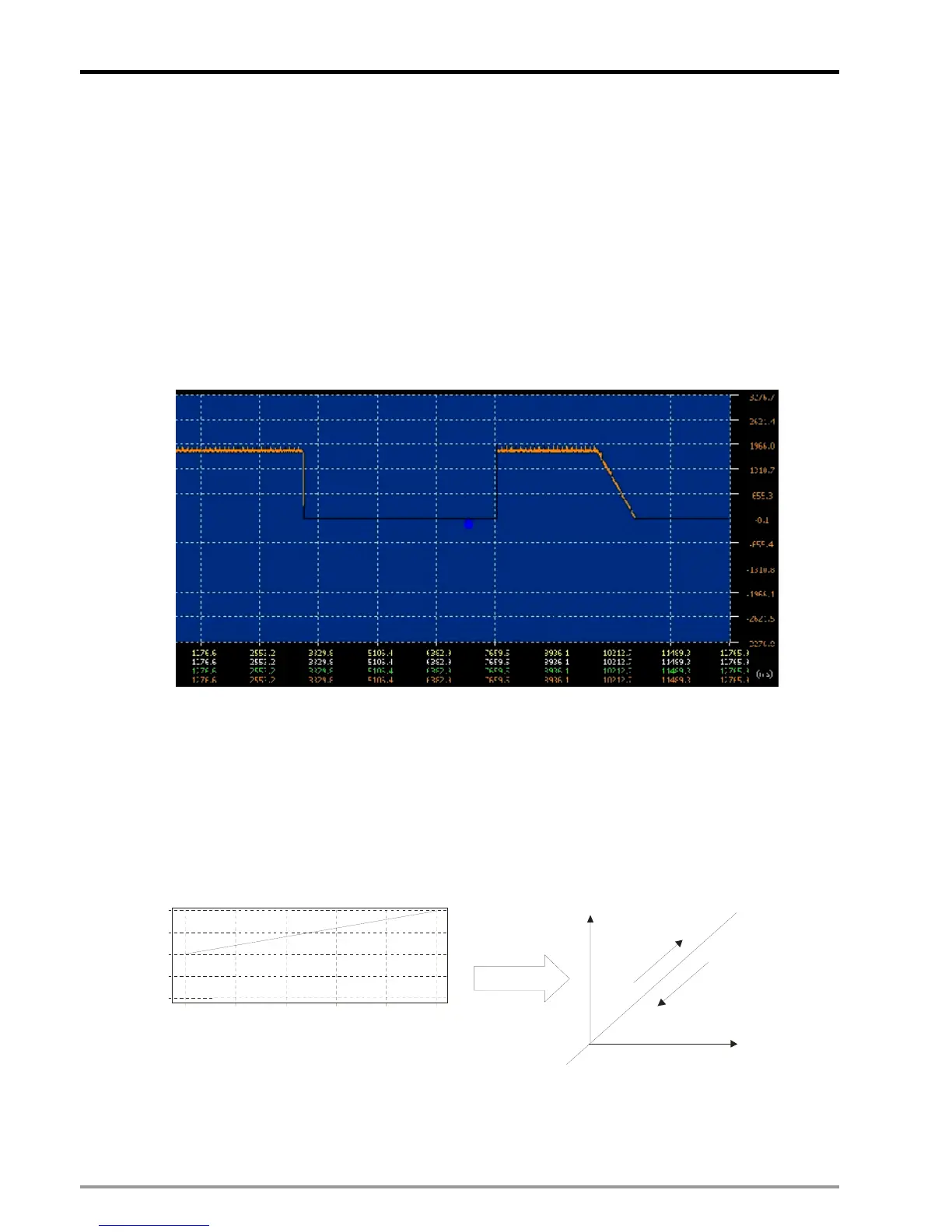

In addition, for point-to-point switching pattern, if E-CAM max frequency (DD1840) is set as 0Hz and the

value of deceleration time T

DEC

(D1837) is specified, E-CAM will decelerate to stop. The below diagram

indicates the diference between normal stop operation and stop operation with deceleration.

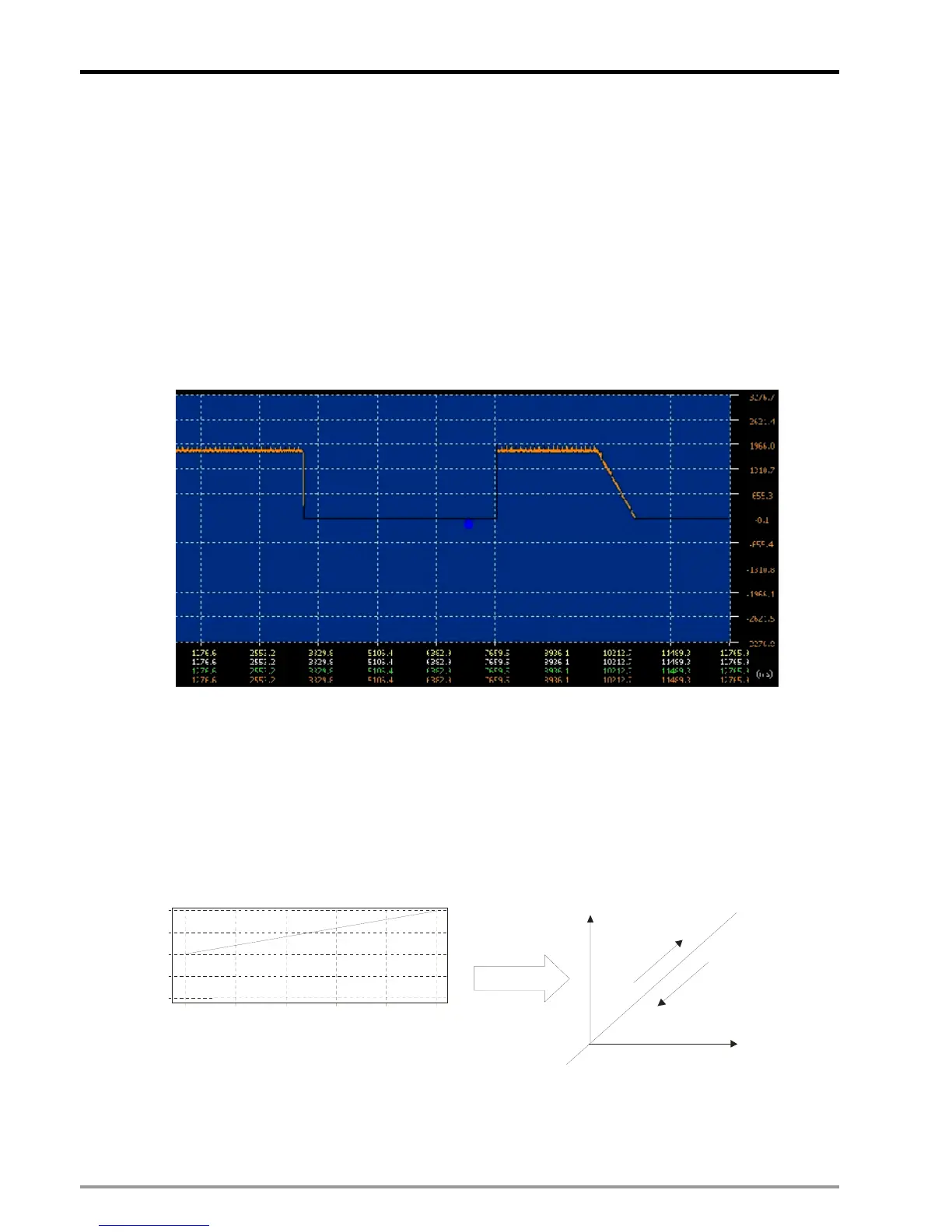

2. Forward / reverse Running Pattern

To enable forward / reverse running pattern, bit 12, 11 of D1847/D1927/D1927 (work mode setting) should

be set ON (K3). In forward / reverse running pattern of multi-axis E-CAM, the execution of Slave will be in

the same direction as Master. In reverse running operation, the execution will start again from the end of the

data when Master position 0 is reached. Therefore, please note that forward/reverse running pattern can not

be used with point-to-point switching pattern otherwise error will occur. The below diagrams illustrate the

execution of 2 E-CAM Charts.

10,000

5,000

0

-5,000

-10,000

2,000

4,000 6,000

8,000

0

10,000

Slav

Loading...

Loading...