Chapter 12 Description of Parameter Settings

ME300

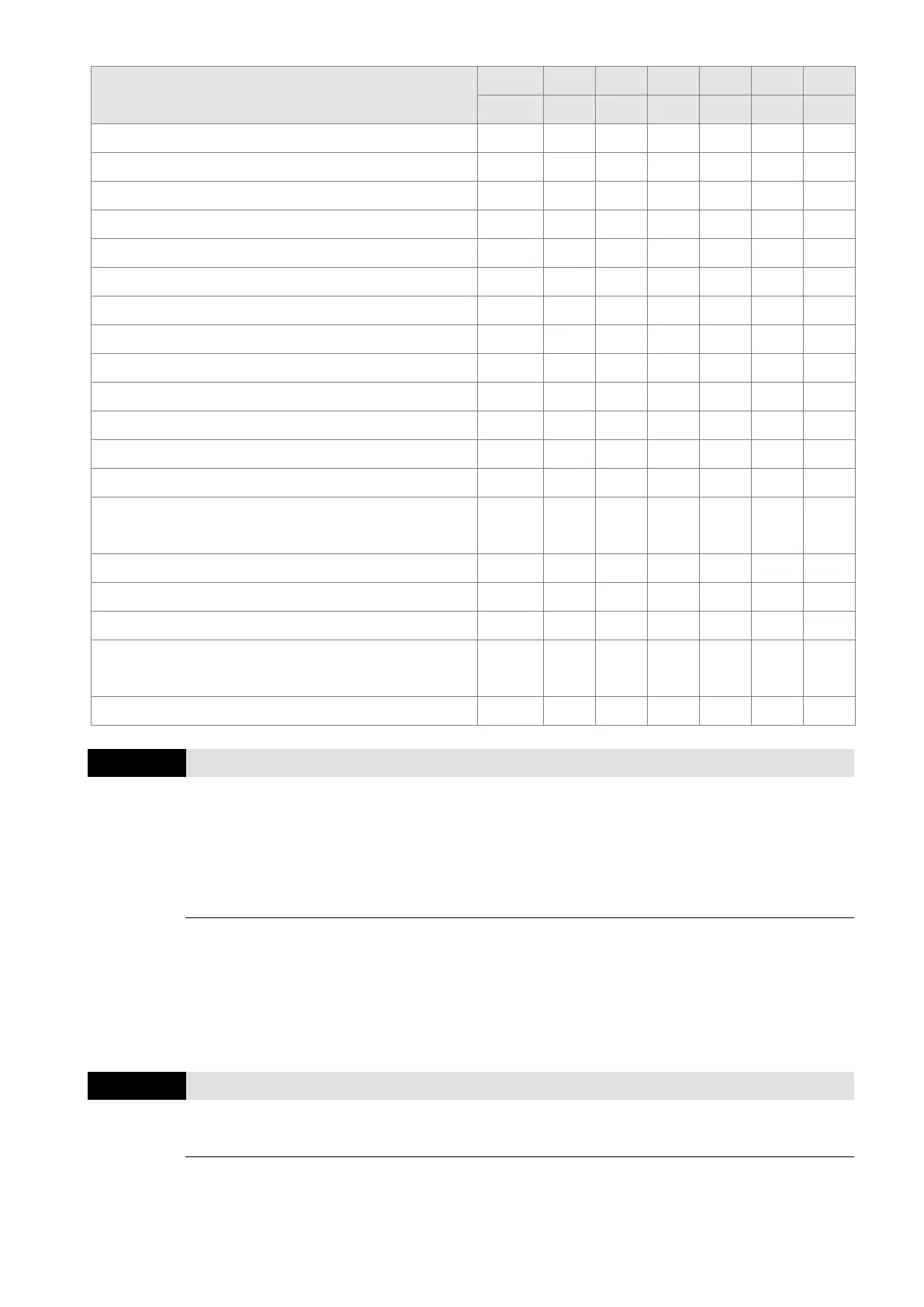

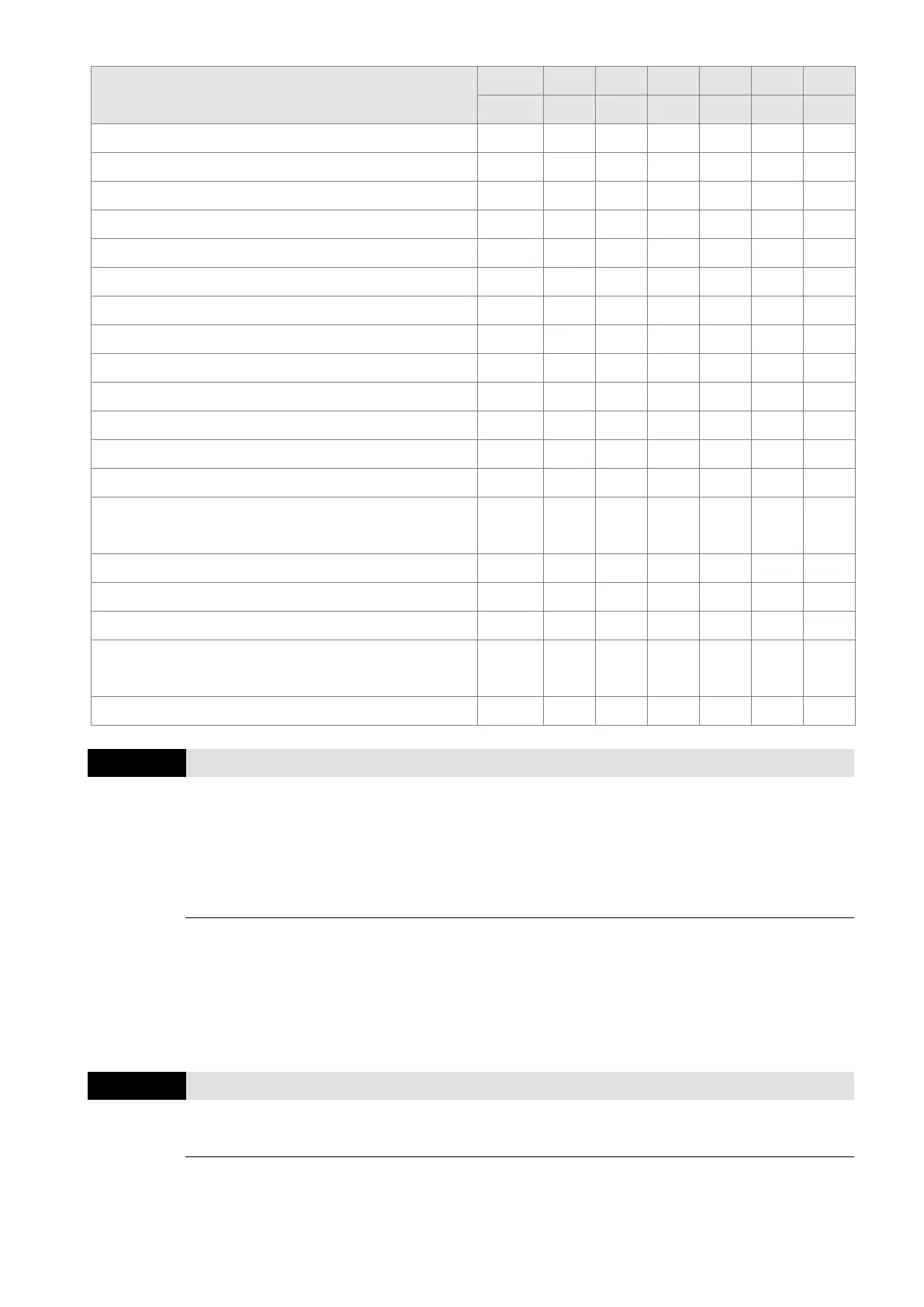

Fault Code

bit 0 bit 1 bit 2 bit 3 bit 4 bit 5 bit 6

current Volt. OL SYS FBK EXI CE

56: Illegal data value (CE3)

●

57: Data is written to read-only address (CE4)

●

58: Modbus transmission time-out (CE10)

●

63: Over-slip (oSL)

●

72: S1 internal loop detection error (STL1)

●

76: STO (STo)

●

77: S2 internal loop detection error (STL2)

●

78: S3 internal loop detection error (STL3)

●

82: Output phase loss U phase (OPL1)

●

83: Output phase loss V phase (OPL2)

●

84: Output phase loss W phase (OPL3)

●

87: Overload protection at low frequency (oL3)

●

142:

Auto-tuning error 1 (DC test stage) (AUE1)

●

143: Auto-

tuning error 2 (High frequency test stage)

(AUE2)

●

149: Total resistance measurement fault (AUE5)

●

150: No-load current IO measurement fault (AUE6)

●

151: dq axis inductance measurement fault (AUE7)

●

152: High frequency injection measurement fault

(AUE8)

●

157: Pump PID feedback error (dEv)

●

Default: 0

Settings 0: Warn and continue operation

1: Fault and ramp to stop

2: Fault and coast to stop

3: No warning

Sets the operation mode of a drive after you set Pr.06-29 to define PTC detection.

Running a motor at low frequency for a long time reduces the cooling function of the motor fan.

To prevent the motor from damage due to overheating, use a Positive Temperature Coefficient

thermistor on the motor, and connect the thermistor output signal to the drive’s analog input

terminals.

Default: 50.0

Settings

0.0–100.0%

Sets AVI / ACI analog input function Pr.03-00 to 6 [Positive temperature coefficient (PTC)

thermistor input value].

Loading...

Loading...