Service

and

Maintenance

I

6.3.1

Cleaning Intervals

6.3 Cooling System

6.3.2 Clean Cooling System

• The amount

of

contamination in the cooling

system dependson the engine application.

• Oil and fuel residues on theengine increase

the risk

of

contamination. Therefore pay

special attention to leaks if the engine is

used in dusty environments.

• Seriouscontamination occurs, forexample:

- on construction sites where there is a high

level

of

air-borne dust.

-

in

harvesting applicationswhere there are

high concentrations

of

chaffand chopped

straw

in

the vicinity

of

the machine.

•

Because

applications

vary,

cleaning

intervals have to be determined from case

to case. The cleaning intervals given

in

the

table below can be used as a guide.

~

o

o

N

©

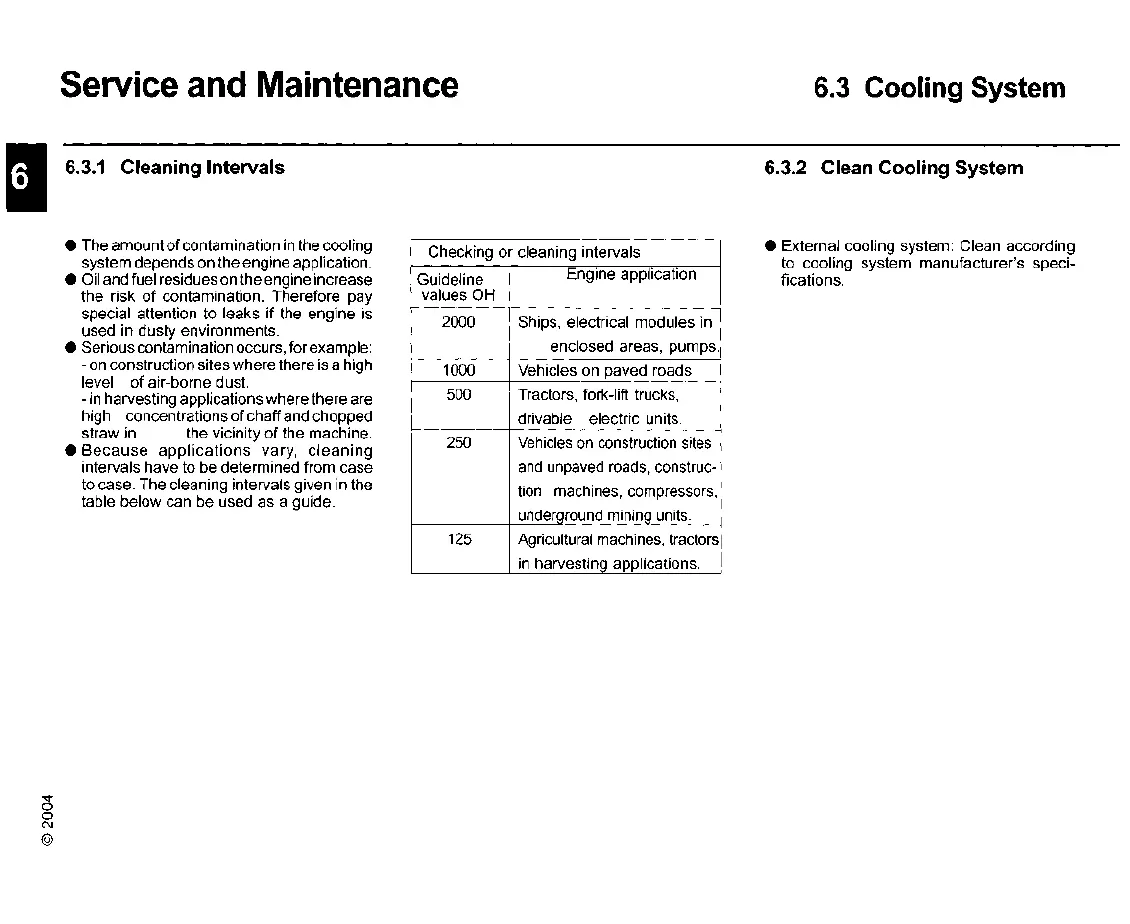

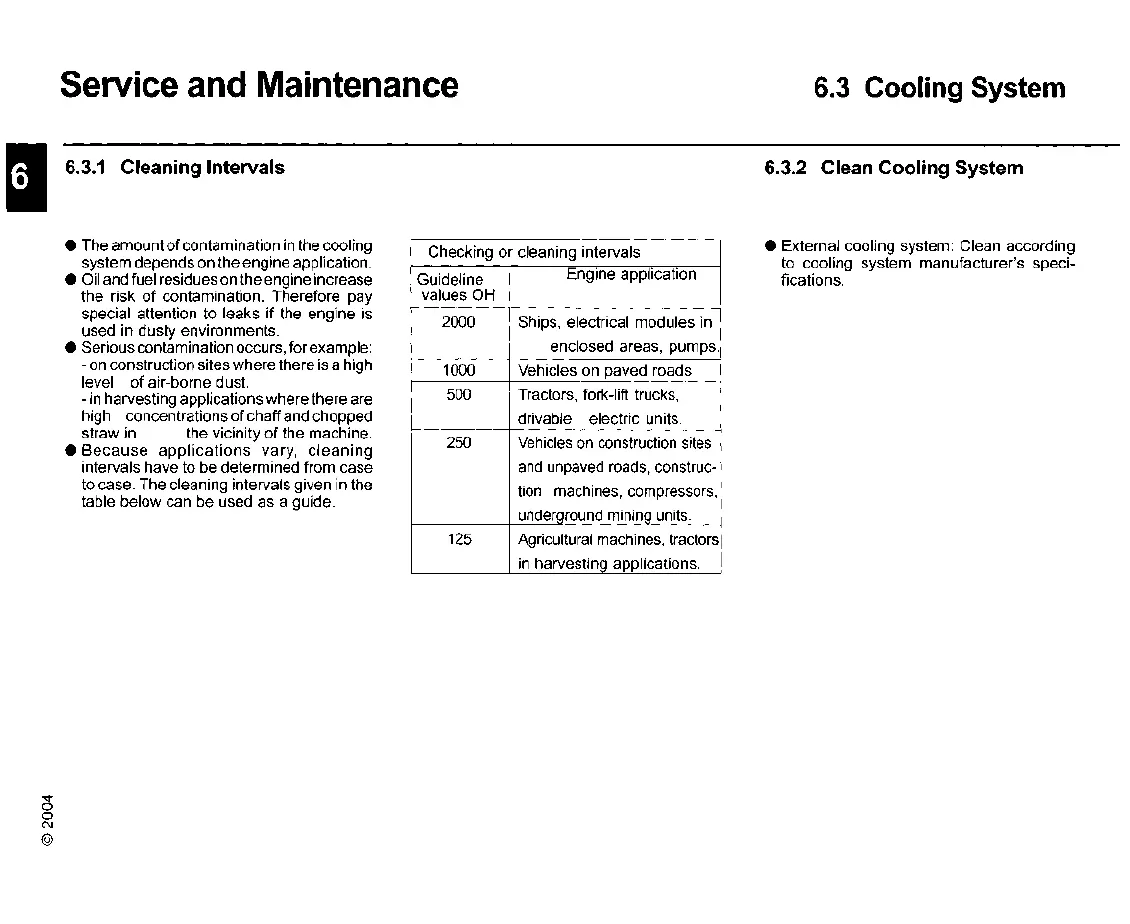

Checking or cleaning intervals

Guideline

Engine application

values OH

2000

Ships, electrical modules in

enclosed areas, pumps.

1000

Vehicles on paved roads

500

Tractors, fork-lift trucks,

drivable

electric units.

250

Vehicles

on

construction sites

and

unpaved roads, construc-

tion machines, compressors,

underground mining units.

125

Agricultural machines, tractors

in

harvesting applications.

• External cooling system: Clean according

to cooling system manufacturer's speci-

fications.

Loading...

Loading...