LT-2329

10

MAINTENANCE

c. Install the new nal bacteria lter with the “IN” tting toward the ow

meter.

6. Inspect the compressor lter (part #1025D-682) during every compressor

service. Replace if the compressor is replaced.

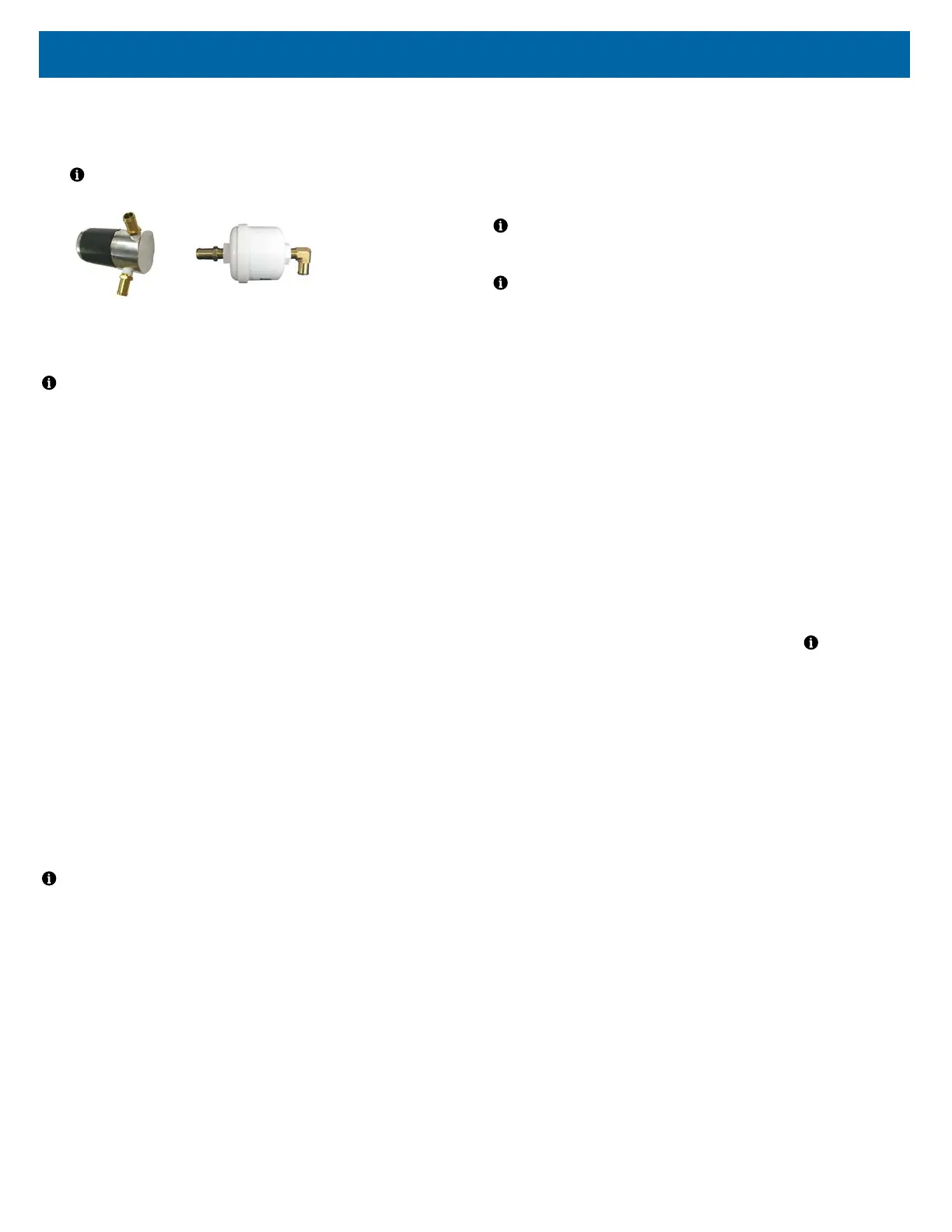

NOTE– A new style compressor lter with an aluminum housing is now

being used. See below:

New Style Old Style (no longer used)

7. Inspect the AC power cord, power switch and circuit breaker between every

patient change. Replace any damaged or defective components.

NOTE– This PM Schedule reects:

• 4000 hour usage equal to one year

• a normal, clean operating environment.

The homecare provider is responsible for:

• determining the condition of the concentrator operating environment.

• determining a preventative maintenance interval frequency* which

takes into consideration the specic operating environment.

* Standard intervals are noted below. Service interval may be more

or less frequent than stated below provided that the Home Care

Provider establishes and documents appropriate protocols.

PREVENTATIVE MAINTENANCE SUMMARY

Patient / Caregiver

Clean and replace oxygen tubing, cannula / mask, and humidier bottle (if used)

according to manufacturer’s instructions.

Homecare Provider

During each inspection

Wash/Replace cabinet lter.

Check audible alert and indicator lights.

During each PM check – every 3 years for the 1025 series

Inspect/Replace intake bacteria lter as necessary.

Check oxygen purity.

During compressor service

Inspect/ Replace nal bacteria lter.

Inspect/ Replace the compressor lter

NOTE– There is no portion of the gas pathways through the concentrator that

could be contaminated with body uids under normal conditions.

The device patient connection may unintentionally become contaminated with

expired gases if a hose internal to the device becomes disconnected. This

condition will cause no ow out of the device and/or an alarm condition. Should

this occur, remove the front cabinet in order to determine where the

disconnection occurred.

Replace all components from the free end of the disconnect through the outlet

port. Reference the pneumatic diagram and replacement part numbers/

instructions.

PROVIDER’S NOTES - Cleaning and

Disinfection When There is a Patient

Change

DeVilbiss Healthcare recommends that at least the following procedures be

carried out by the manufacturer or a qualied third party between uses by

different patients.

NOTE– If the following described complete processing of the concentrator by

an appropriately trained individual is not possible, the device should not be used

by another patient.

NOTE– If preventive maintenance is due at this time, these procedures

should be carried out in addition to the servicing procedures.

1. Use disinfectants safely. Always read the label and product information

before use.

2. Always wear personal protective equipment when performing this

procedure. Use suitable gloves and safety glasses. Cover exposed skin on

arms to prevent accidental contact with bleach solution that has been

applied to the concentrator.

3. Dispose of all accessories that are not suitable for reuse. This includes but

may not be limited to the oxygen tubing, tubing connectors, nasal cannula

and/or mask, oxygen outlet connector, and humidier bottle.

4. Clean the exterior of the concentrator with a clean lint-free cloth. Heavy soil

should be removed with a clean lint-free cloth dampened with water. A soft

bristled brush dampened with water can be used to remove stubborn soil.

Dry the concentrator using a clean lint-free cloth if water was used to

remove soil.

5. Use 5.25% chlorine bleach (Clorox Regular Liquid Bleach or equivalent).

Mix one (1) part bleach with four (4) parts water in an appropriate clean

container. This ratio produces a one (1) part bleach to ve (5) total parts

solution (1:5). The total volume (amount) of solution required is determined

by the number of concentrators in need of disinfection.

NOTE– An

alternate suitable disinfecting agent (e.g. Mikrobac® forte or Terralin®

Protect) may also be used. Follow disinfectant manufacturer’s instructions.

6. Apply the bleach solution in an even manner to the cabinet and power cord

using a clean lint-free cloth. The cloth should be dampened only and not

dripping of solution. Do not use a spray bottle to apply the solution. Do not

saturate the device with the solution. Take care that no solution enters the

vent areas on the concentrator base or the Auxiliary O2 tting area on the

back of the unit. Avoid over-saturating the cabinet seams so that no solution

residue builds up in these areas. Avoid the caster wells located on the

bottom of the unit.

7. Exposure time of the disinfectant solution should be 10 minutes minimum to

15 minutes maximum.

8. After the recommended exposure time, all surfaces of the concentrator

should be wiped with a clean lint-free cloth dampened with drinking quality

water no warmer than room temperature. Dry the unit with a dry, clean lint-

free cloth. This is to remove residue that may stain or leave a lm on the

unit, especially after repeated disinfections.

9. Check the cord, the plug on the back of the device, the power switch, the

fuse holder, and the indicator lights for possible damage. Replace all

damaged or worn components.

10. Replace the cabinet air lter on the back of the device.

11. Check the oxygen concentration. If the device is within specication, the

extended life intake bacteria lter does not need to be replaced between

patients. If the oxygen concentration is not within specication, the provider

should refer to the service manual section on Troubleshooting.

12. OPTIONAL INSIDE CLEANING: The concentrator must be disconnected

from the power supply for this step: Open the concentrator and remove all

dust deposits inside the cabinet with an appropriate vacuum cleaner. Close

the concentrator.

Loading...

Loading...