19

LT-2329

COMPONENT TESTING, REPAIR AND REPLACMENT

CHECK VALVES / MANIFOLD

Manifold And Sieve Bed Check Valves

The manifold check valves, located in the manifold attached to the accumulator

tank, and the sieve bed check valves, located in the purge harness between the

outlet of each sieve bed and the accumulator tank, allow oxygen to pass from the

sieve beds to the accumulator tank when the bed pressure is greater than the

accumulator tank pressure. These valves also prevent reverse ow of oxygen

from the accumulator tank to the sieve beds.

The manifold also directs a small amount of pressurized oxygen into the

discharging sieve bed to aid the nitrogen exhaust process. The purge harness

includes a xed orice that performs the same function.

A defective manifold or sieve bed check valve will result in lower oxygen

concentrations and accumulator pressures.

Use the Accumulator Pressure Test listed previously to troubleshoot manifold or

sieve bed check valves.

• To replace a defective sieve bed check valve, remove the tubing on either

side of it and install a new valve making sure the outlet end is toward the

accumulator tank.

• To replace a defective manifold check valve, replace the manifold.

NOTE– Also see Manifold section on page 22.

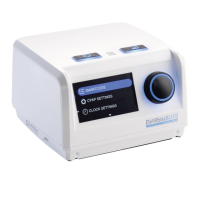

COMPRESSOR

The Drive DeVilbiss Oxygen Concentrator uses a double-head, oil-free

compressor. The compressor is secured to the base with a mounting plate and

four motor mounts.

Electrical Connector

Exhaust Fitting

Intake Fitting

Pressure Relief Valve

Changes were made to the original compressor in January, 2020. These changes

include a redesigned valve plate and sleeve with heat sink. All 1025 models now

have the updated compressor. See gures below.

(Updated compressor

with redesigned valve

plate and sleeve.)

Sleeve w/Heat Sink Valve Plate

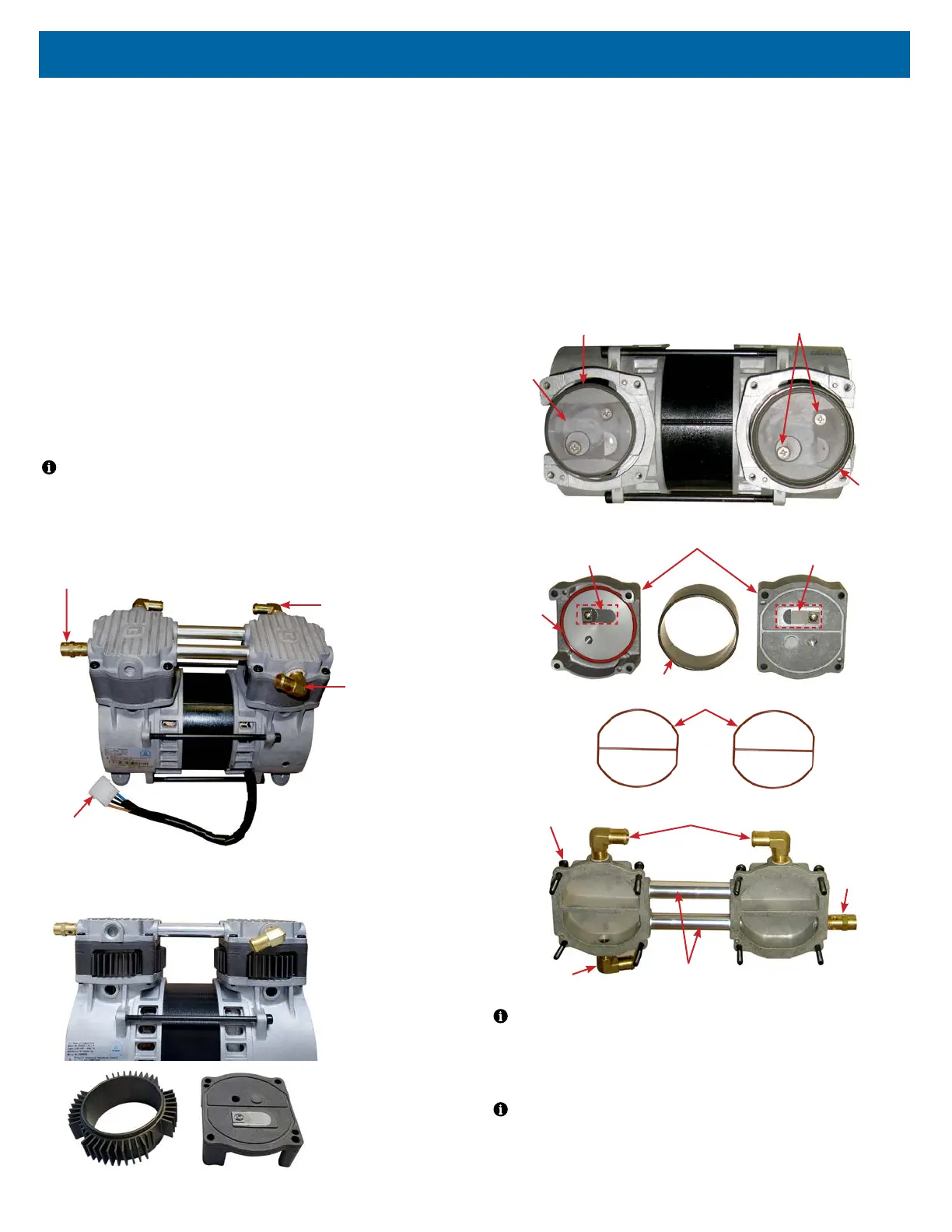

A compressor that is worn or defective may:

• cause pressure to rise slowly.

• cause excessive noise and/or vibration.

• cause lower oxygen concentrations.

A worn or defective compressor can be caused by a defective internal

component such as:

• reed valve

• o-ring

• gasket

• cup seal

These components are included in the Compressor Rebuild Kit (1025D-643 and

1025K-643).

Sleeve

Rod Screw

Cup Seal

Cup

Retainer

Valve Plate

Bottom Reed

Valve & Retainer

O-Ring

Sleeve

Top Reed Valve

& Retainer

Head Gaskets

Intake Fittings

PR

Valve

Head Screw

Connecting

Tubes

Exhaust

Fitting

NOTE– A built-in thermal cutoff switch will shut the compressor off if it

becomes overheated. This protects the compressor from damage caused by heat

build-up. (Some models have an auxiliary thermostat mounted within the

compressor compartment.) Should this condition occur, the compressor will

require several minutes for the thermo-protective device to reset.

NOTE– A pressure relief (PR) valve is located on the pressure head to

prevent high pressure build up in the system should a component malfunction

occur.

Loading...

Loading...