LT-2329

24

COMPONENT TESTING, REPAIR AND REPLACMENT

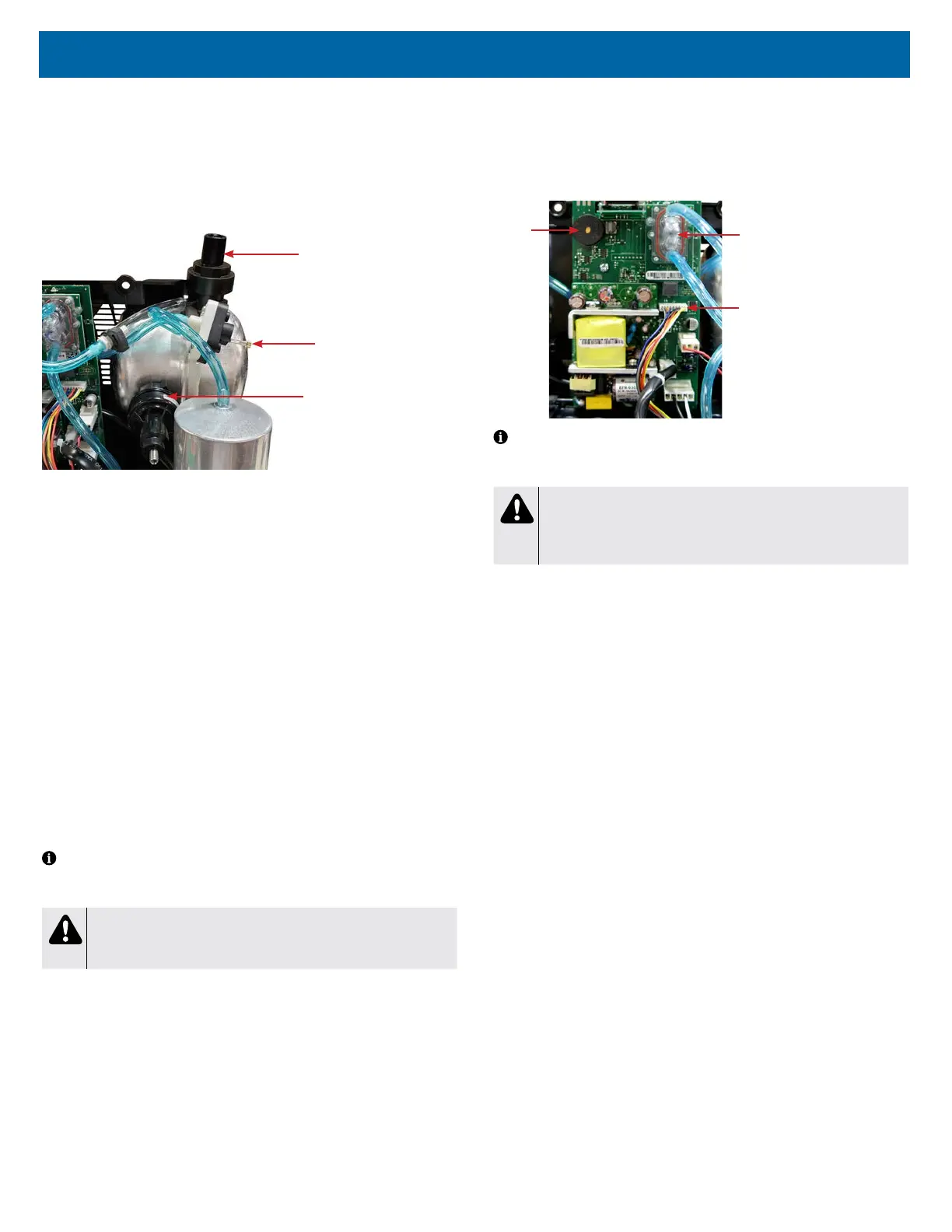

PRESSURE REGULATOR

The 1025 series has two pressure regulators. One regulates the outlet pressure

to the patient and the other regulates pressure to the auxiliary oxygen port. The

regulator located at the top of the accumulator tank is connected to the OSD and

stabilizes the ow of oxygen to the patient and establishes back pressure on the

system. It is pre-set at 20 ± 1 psi (137.8 ± 7 kPA) and should not have to be

adjusted in the eld.

Regulator for Auxillary

Oxygen Port

Pressure Test Point

Regulator for Outlet

Pressure to Patient

It is not necessary to test the pressure regulator unless there is a problem with

ow rate accuracy. The following test is only needed when troubleshooting ow

rate issues.

To test the pressure regulator:

1. Turn the unit “On.”

2. Set the ow meter at 2-3 lpm.

3. Attach a pressure gauge (part #PVO2D-601) to the oxygen outlet to obtain

a reference pressure. Use this reference pressure to determine if further

testing is needed.

4. If the reference pressure varies from the expected pressure by more than ±

1 psi or ± 7 kPa, connect a ‘T’ tting directly between the pressure regulator

tting and the pressure regulator tubing and attach the pressure gauge to

the 3rd leg of the ‘T’ tting. If the pressure reading is not within

20 ± 1 psi (137.8± 7 kPa), adjustment to the pressure regulator is required.

To adjust the pressure regulator:

1. If necessary, the pressure regulator can be adjusted by turning the allen

screw on top of the regulator until the pressure is within specication. Turn

clockwise to increase the pressure, and counterclockwise to decrease the

pressure.

NOTE– Before adjusting the pressure regulator, make sure no leaks exist by

using a certied leak detection solution such as Snoop® or equivalent (must not

contain ethylene glycol).

CAUTION

Do not apply leak test solution to any part of the rotary valve or the

main PC Board assembly.

A malfunction in the pressure regulator will cause either a loss or uctuation in

the oxygen ow which will be seen on the ow meter or a decrease in oxygen

concentration.

To replace the pressure regulator:

1. Make sure the unit is unplugged from the wall outlet.

2. Use the Cabinet Removal instructions listed previously to open the unit.

3. Remove the tubing clamp and tubing from the pressure regulator.

4. Unscrew the regulator from the accumulator tank.

5. Install a new regulator on the accumulator tank and attach the tubing and

tubing clamp.

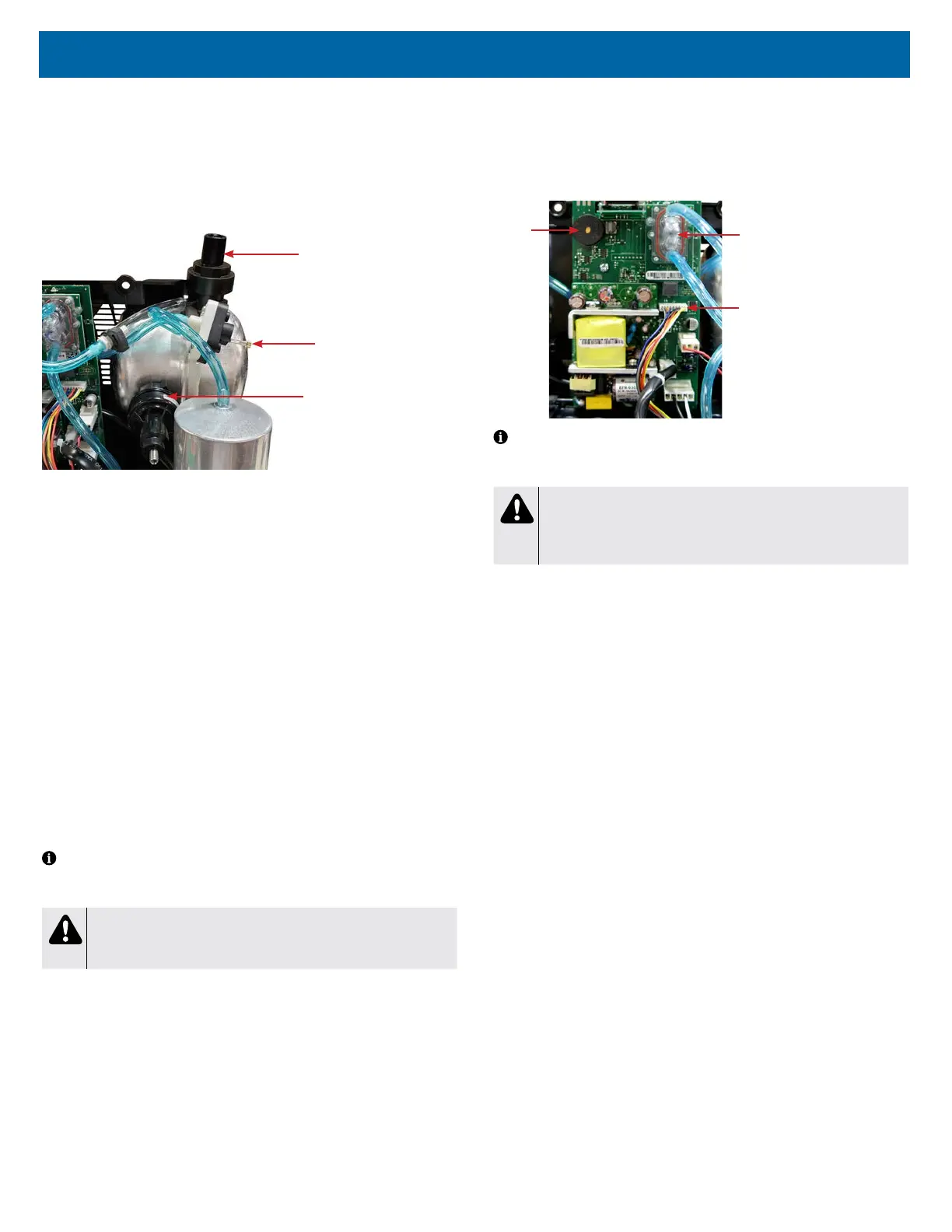

PRINTED CIRCUIT BOARD

The printed circuit (PC) board is responsible for monitoring and controlling the

Drive DeVilbiss Oxygen Concentrator.

The PC board has preset alerts for low ow and power failure. Should any of the

alert values be exceeded, the patient alert system will activate.

Rotary Valve

Wire Harness

Alarm

OSD

NOTE– If the concentrator has been unused for an extended period, the unit

must run 20 minutes before the power fail alert will be enabled. This alert is

powered by a capacitor on the PC board.

CAUTION

Do not apply any force or ex to the PC Board when connecting or

disconnecting electronic or pneumatic components. Damage to the

electronic assembly is possible.

To remove and replace the PC board:

1. Make sure the unit is unplugged from the wall outlet.

2. Use the Cabinet Removal instructions listed previously to open the unit.

3. Disconnect all wires and electrical connectors.

4. Remove the 1/8" (3.2mm) tubing from both ttings on the oxygen sensor.

5. Remove the screw that secures the board to the unit and remove the PC

board.

6. Install the new PC board and secure it using the screw.

7. Reconnect all electrical wires, connectors and the tubing to the sensor.

Loading...

Loading...