17

LT-2329

COMPONENT TESTING, REPAIR AND REPLACMENT

PROPER REPAIR PROCEDURES

WARNING

When servicing the Drive DeVilbiss Oxygen Concentrator, be

absolutely certain that the correct tools are used and that the parts

are free of oil and grease or any material not compatible with oxygen.

Teon

®

tape is recommended and must be applied to the male

threads omitting the rst thread to eliminate the possibility of tape

particles entering the oxygen system.

Electric shock hazard. Do not remove cabinet. The cabinet should

only be removed by a qualied Drive DeVilbiss homecare provider.

Disconnect the power cord from the wall outlet before attempting

repairs on the unit. Extra care should be taken if it is necessary to

operate the unit with the cabinet removed.

NOTE– Be sure to read all of the steps involved before beginning any of the

procedures in this manual.

NOTE– After repairing or replacing a component, run the unit for 20 minutes,

check the oxygen concentration and test for leaks.

The DeVilbiss Oxygen Concentrator is designed for ease of service. To aid

service personnel a Service Kit (part #444-501) is available which contains the

necessary gauges, tools, and testing instruments to properly service the oxygen

concentrator. See list below.

In addition, you will also need an oxygen analyzer (part #R217P62) to

periodically check oxygen concentration levels and leak test solution.

The following parts are included in the Service Kit:

1 Slotted bit

1 #1 Phillips bit

1 #2 Phillips bit

1 Crescent wrench

1 8” Duckbill pliers

1 Voltmeter

2 Pressure/Vacuum gauge

1 Tool box

2 Test Fittings

1 Torx screwdriver w/bits

1 Channel Lock Pliers

1 1/4” Ratchet wrench

1 10mm Socket l/4” Drive

1 1/4” Drive extension

1 Plastic storage case

CABINET REMOVAL

The majority of all the servicing and repairs can be done without removing the

front cabinet completely. However, it may be loosened or removed to gain access

to the components behind it.

To remove back cabinet:

1. Unplug the unit from the wall outlet.

2. Remove the six screws that secure the back cabinet – 2 behind handle, 2

near the bottom, and 1 on each side.

NOTE– All six screws are the same size.

3. Remove the back cabinet by sliding it toward the rear until clear.

4. To reassemble, reverse steps 2-3.

To loosen the front cabinet:

5. Remove the two screws (located directly above the intake bacteria lter)

that hold the front cabinet to the unit’s internal structure.

6. Remove the screw located near the bottom of the recessed humidier

compartment on the front of the unit. The top of the front cabinet can now

be tilted forward to allow access to the components behind it.

To remove the front cabinet completely:

7. Tilt cabinet forward.

8. Before disconnecting the wires from the power switch and circuit breaker

note their positions in order to reconnect them properly; then disconnect the

wires.

9. Disconnect the hose at the bottom of the ow meter and remove cabinet.

10. To reassemble reverse steps 5 – 9 making sure bottom of cabinet is

inserted securely in base of unit.

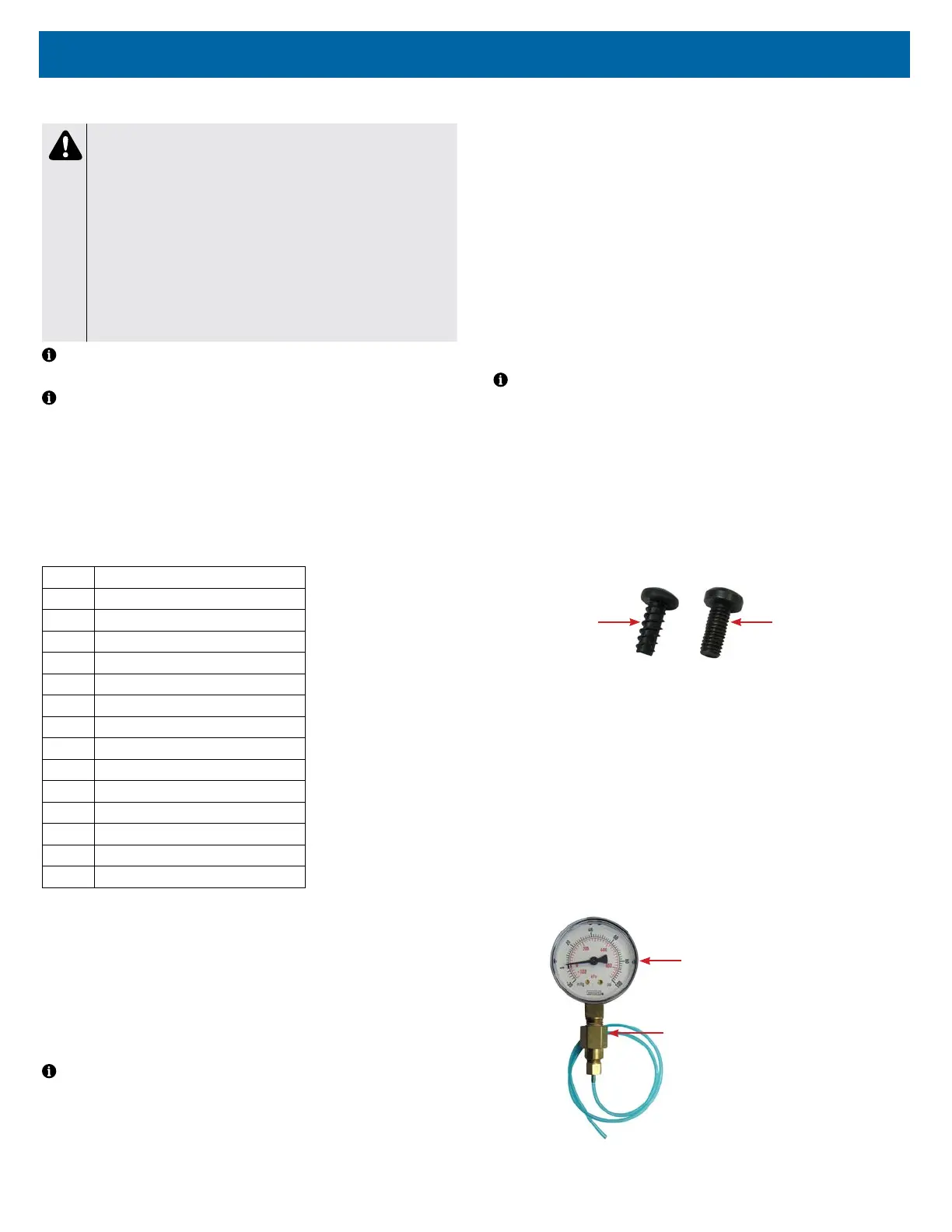

NOTE– Two types of cabinet screws are used in the 1025 models, thread-

forming screws and machine screws. Do not overtighten the thread-forming

screws; they should be torqued to 18 –20 in-lbs. The machine screws have much

ner threads and are used in conjunction with brass inserts that are molded into

the cabinet part; they should be torqued to 20 – 25 in-lbs.

When replacing a cabinet part such as the front cover, base or compressor box

be sure to use the correct screw. The ne threaded machine screws should

always be used if there is a brass insert. Thread-forming screws should be used

if there is no brass insert molded into the cabinet part.

These screws are not interchangeable, so be sure to order the correct part

number. See gure below.

Thread-forming

Cabinet Screw

(525DD-636)

Machine Cabinet

Screw (525DD-628)

ACCUMULATOR TANK

The oxygen accumulator tank holds the concentrated oxygen and releases it to

the patient at a specied liter ow.

ACCUMULATOR PRESSURE TEST

To check accumulator pressures:

1. Make sure the unit is “Off.”

2. Use the Cabinet Removal instructions listed previously to open the unit for

testing.

3. Use the pressure gauge (part #PVO2D-601) and pressure test assembly

(part #303DZ-637) included in the Service Kit.

Pressure Gauge

Pressure Test

Assembly

Loading...

Loading...