9

LT-2329

MAINTENANCE

condition.

d. Reconnect the AC power cord and conrm that the alarm condition

ends.

8. Malfunction – O2S Gas Temperature High

a. This alarm condition is tested automatically during start-up.

9. Malfunction – Corrupted Settings

a. This alarm condition is tested automatically during start-up.

10. Malfunction – Non-Recoverable Valve Error

a. This alarm condition is tested automatically during start-up.

11. Malfunction – O2S Oxygen Sensor Communication Failure

a. This alarm condition is tested automatically during start-up.

12. Low Oxygen Concentration – Startup Period

a. Connect the oxygen concentrator to AC power and turn the power

switch off.

b. Leave the device off for several minutes until the outlet ow is zero

(ow meter ball at zero).

c. Turn the power switch to the on position. The alarm condition (yellow

light) occurs during startup until the oxygen concentration reaches

85%.

13. Low Oxygen Concentration – Startup Period Over

a. This alarm condition is tested automatically during start-up. Once the

oxygen concentration reaches 85% the green light comes on.

SERVICE LIFE

The expected service life of the 1025 is 5 years of operation, when used in

accordance with all manufacturer guidance for safe use, maintenance, storage,

handling and general operation. Expected service life of the unit, and in

particular the sieve beds and compressor, may vary based on the operating

environment, storage, handling and the frequency and intensity of use.

ROUTINE PATIENT MAINTENANCE

DeVilbiss recommends using only original DeVilbiss parts and lters in order to

guarantee a reliable operation of the product.

The oxygen patient should perform the following maintenance:

Cannula, Tubing, and Humidifier Bottle

The patient should clean and replace the cannula, tubing, and humidier bottle

according to the manufacturer’s instructions.

Air Filter

The air lter should be inspected periodically and cleaned as needed by the

user or caregiver. Replace if torn or damaged. To clean, follow these steps:

NOTE– Frequency of inspection and cleaning of lter may be dependent

upon environmental conditons like dust and lint.

1. Remove the air lter located in the door on the back of the unit.

2. Wash in a solution of warm water and dishwashing detergent.

3. Rinse thoroughly with warm tap water and towel dry. The lter should be

completely dry before reinstalling.

CAUTION

Do not attempt to operate the unit without the air lter or while the

lter is still damp

NOTE– The air lter should be monitored more closely in environments with

abnormal amounts of dust and lint.

CAUTION

Operation of the Drive DeVilbiss Oxygen Concentrator in extreme

environments or without the air lter will prematurely occlude the

intake bacteria lter and cause a decrease in the unit performance.

Exterior Cabinet

The patient should clean the concentrator exterior cabinet weekly by using a

damp cloth or sponge with a mild household cleaner and wiping it dry.

WARNING

Do not apply liquids directly to the cabinet or utilize any petroleum-

based solvents or cleaning agents.

PERIODIC HOMECARE PROVIDER

PREVENTATIVE MAINTENANCE

Use only DeVilbiss concentrator replacement parts and accessories.

Every Drive DeVilbiss Oxygen Concentrator is tested at the factory. To assure

continued trouble-free performance, the following preventative maintenance

should be performed by the homecare provider during periodic oxygen patient

visits. Failure to properly maintain the unit will void the warranty.

1. Check the oxygen concentration with an oxygen analyzer (part #R217P62)

– every 3 years.

a. Calibrate the oxygen analyzer prior to checking the oxygen

concentration. The analyzer should be properly calibrated using the

manufacturer’s recommended procedure.

NOTE– Changes in temperature, altitude or humidity may affect the

analyzer’s oxygen concentration reading. The analyzer should be calibrated in

similar conditions to the location of the concentrator.

b. Power the unit. Set the ow meter to 10 LPM and connect the

analyzer to the unit’s oxygen outlet port.

c. Wait 20 minutes for the display to stabilize. The concentrator must

operate for a minimum of 20 minutes before checking the oxygen

concentration.

d. Record the reading.

2. Check the audible alert and indicator lights during every service. When the

power is turned “ON,” listen for the audible alert and check to see if the

front panel indicator lights are operating.

3. Inspect cabinet air lter (part #303DZ-605) every PM check. Replace if

lter is torn or damaged.

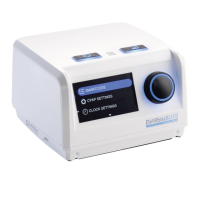

4. Inspect intake bacteria lter (part #1025D-605) at every PM check.

Replace if the lter looks dirty or there is a drop in oxygen purity.

a. Open the lter door and replace lter as required.

Air Intake Holes

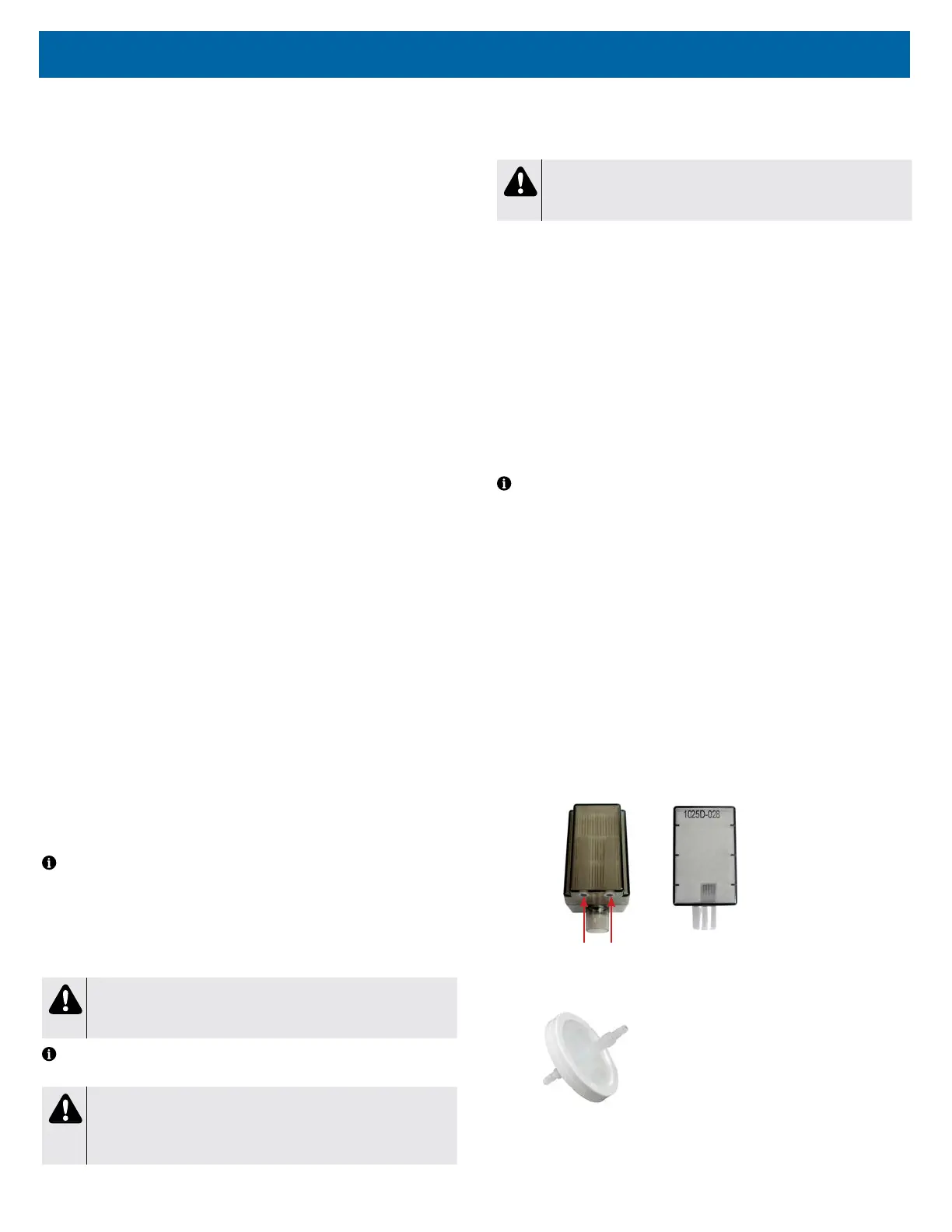

5. I nspect the nal bacteria lter (part #PV5LD-651) during every compressor

service.

a. Use the Cabinet Removal instructions found under CABINET

REMOVAL in this manual to remove and attach the cabinets.

b. Remove the hose from each end of the lter and discard the lter.

Loading...

Loading...