LT-2329

18

COMPONENT TESTING, REPAIR AND REPLACMENT

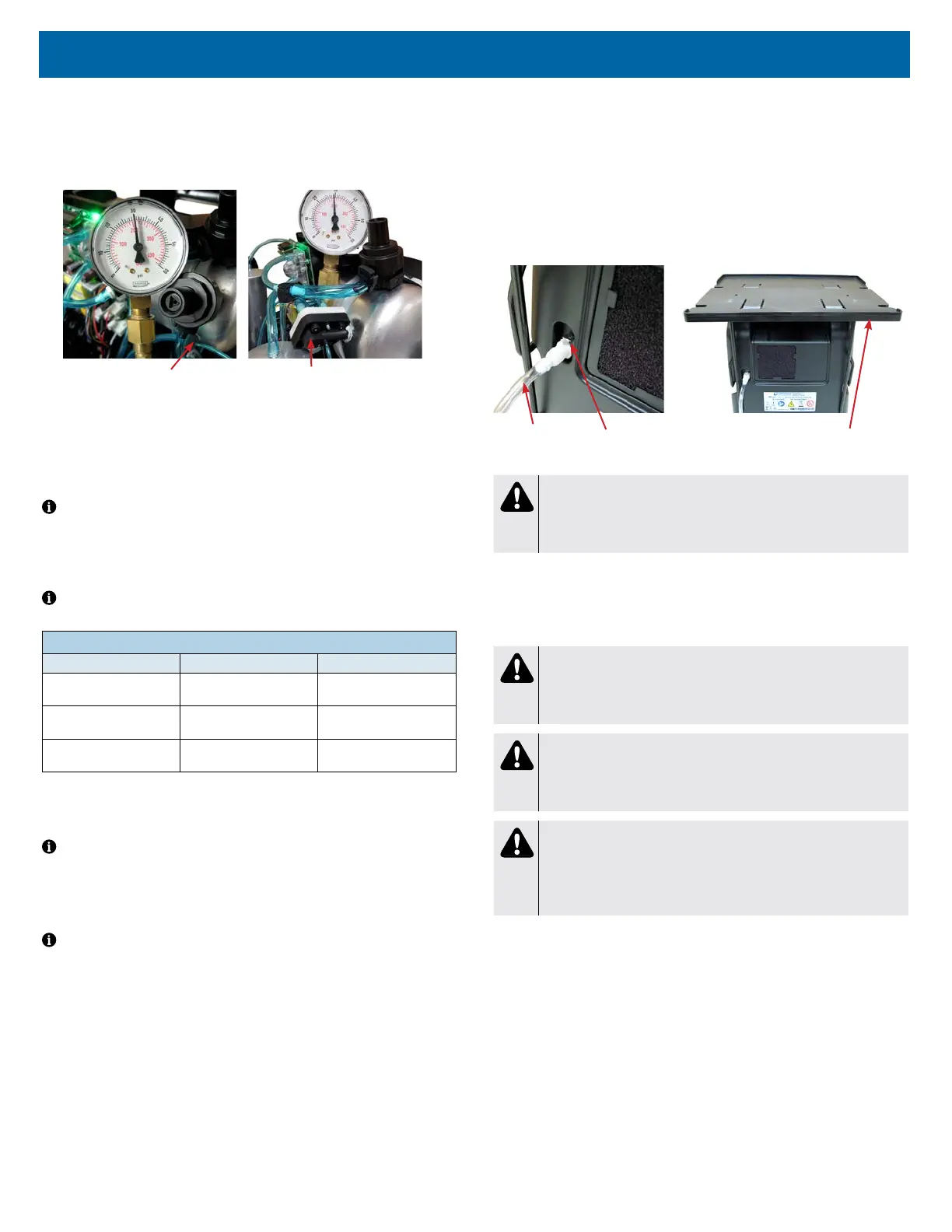

4. Remove the tubing cap from the accumulator tank tting or from the

manifold attached to the tank, and attach the 1/16" (1.6 mm) diameter

tubing from the gauge to the tting just vacated above.

See Figures below showing pressures being checked at accumulator tank

"T" tting and manifold.

Accumulator "T" Fitting Manifold

5. Turn the unit “On” with the ow rate set to maximum recommended ow,

which is 10 lpm. Allow the unit to run for 5 minutes before observing the

pressures. During each timed cycle, the average pressure in the oxygen

accumulator will rise and fall. The high pressures should be consistent and

the low pressures should be consistent. The pressure swing will be

approximately 4-5 psi.

NOTE– Expected normal pressures observed depend on altitude and ow

rate. See the Typical Peak Accumulator Tank Pressure Range chart below.

• Increases in altitude and ow rate will slightly decrease accumulator

pressures.

• Lower altitudes and ow rates will slightly increase accumulator pressures.

NOTE– A defective check valve in the purge harness may cause a rapid drop

in accumulator pressure below the minimum value.

TYPICAL PEAK ACCUMULATOR TANK PRESSURE RANGE @ 10LPM

Altitude Psi kPa

0 to 457 m

0 to 1500 ft.

25-36 172-248

457 to 914 m

1500 to 3000 ft.

21-33 145-228

914 to 1524 m

3000 to 5000 ft.

21-30 145-207

6. Refer to the Type 1 – Purity Issues, found under Simplied Troubleshooting,

to determine the appropriate action to take in resolving abnormal pressure

cycles.

NOTE– A defective compressor will be indicated by slowly rising pressure.

Pressure may only reach a certain level and then stop.

Low oxygen concentration levels and accumulator pressures higher than normal

may indicate defective sieve beds. Severely contaminated beds may also cause

the pressure relief valve on the compressor to open.

NOTE– A malfunctioning rotary valve may also cause high accumulator tank

pressure and activation of the pressure relief valve. In this case it should be

determined whether the problem is with the sieve beds, valve, or both.

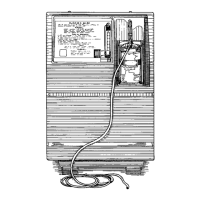

AUXILIARY OXYGEN PORT

All 1025 series concentrators are manufactured with an auxiliary oxygen port

located on the back of the unit.

To ll oxygen cylinders:

This external port can be used to ll oxygen cylinders with an FDA-cleared

cylinder lling device that is designed to use oxygen from a concentrator to

ll a cylinder. The port is only for use with FDA-cleared lling devices with

compatible oxygen input specications.The ow meter should be set at 6

LPM or less when the concentrator is being used during cylinder ll. The

port does not affect concentrator performance if properly used. See gures

below.

Auxiliary Port Output Specications:

Outlet Pressure ........................................ <15 psi

Outlet Flow ............................................. 2.0 LPM

Outlet Oxygen ..............................................>90%

Operation Time ................................... Continuous

Refer to the cylinder lling device instruction guide for the oxygent input/output

specications, connection and operating instructions.

Transfill Hose

(PF1100TUB)

Auxiliary Port

Transfiller Caddy

(525DD-650)

WARNING

When using the Transller Caddy with a Transll device, always keep

the system on a at surface. Disassemble the system prior to

moving.

CAPACITOR

The capacitor enables the compressor to start and run by supplying voltage to

the windings of the compressor motor. A defective capacitor will result in the

compressor running slower or not starting.

CAUTION

The 1025DS concentrators use a GSE compressor with a 60 mfd

capacitor. If replacement is necessary, be sure the correct capacitor

is installed.

CAUTION

The 1025KS/1025UK concentrators use a GSE compressor with a

17.5/15 mfd capacitor respectively. If replacement is necessary, be

sure the correct capacitor is installed.

WARNING

Electric Shock Hazard. When replacing the capacitor, do not touch

the terminals or allow metal objects to come in contact with the

terminals on the capacitor. The capacitor may hold a charge for

several days after the unit is turned off.

If a defective capacitor is suspected, a new one must be installed. The capacitor

is located beside the intake lter or next to the cooling fan in the base of the unit.

To replace the capacitor:

1. Make sure the unit is unplugged from the wall outlet.

2. Remove the back cabinet and also loosen the front cabinet and tilt it

forward. Use the cabinet removal instructions listed previously.

3. Disconnect the two wires from the terminals on the capacitor.

4. Cut the nylon cable tie holding the capacitor in place and remove the

capacitor.

5. Install the new capacitor and secure with a new cable tie.

6. Reconnect the wires to the new capacitor.

7. Replace both cabinets and secure with screws.

Loading...

Loading...