TB-1022

6

INSTALLATION

For maximum transfer efciency, do not use more pressure than

is necessary to atomise the material being applied.

1. Connect the gun to a clean, moisture and oil free air

supply using a hose size of at least 8 mm (5/16") I.D. hose.

Do not use 6 mm I.D. hose (8 m x 6 mm hose at 510 LPM

has a pressure loss of 1.8 bar. 8 m x 8 mm hose at 510 LPM

has a pressure loss of 0.6 bar. [Do not use 1/4" I.D. hose

(25' x 1/4" hose at 18 CFM has a pressure loss of 25 psi.

25' x 5/16" hose at 18 CFM has a pressure loss of 8 psi).]

Depending on hose length, larger I.D. hose may be required.

NOTE

When gun is triggered on, adjust inlet air pressure

(for recommended pressures see Chart 1 under Parts

Replacement) at the gun inlet. (Pressure gauge shown under

Accessories is recommended for this). Do not use more

pressure than is necessary to atomise the material being

applied. Excess pressure will create additional overspray and

reduce transfer efciency.

NOTE

If quick connects are required, use only high ow quick

connects approved for HVLP use. Other types will not ow

enough air for proper gun operation.

NOTE

If an air adjusting valve is used at the gun inlet, use a DeVilbiss

air adjusting valve. Some competitive adjusting valves have

signicant pressure drop that can adversely affect spray

performance. DeVilbiss air adjusting valves have minimal

pressure drop.

2. Attach the uid supply hose to the uid inlet connector.

NOTE

Protective coating and rust inhibitors have been used

to keep the gun in good condition prior to shipment.

Before using the gun, ush it with solvents so that these

materials will be removed from uid passages.

OPERATION

1. Mix coating material to manufacturer’s instructions and strain

material.

2. Fill the pressure cup with the required amount of material.

DO NOT OVERFILL.

3. Attach Cup Lid.

4. Turn uid adjusting knob (28) clockwise to prevent uid

needle movement.

5. Turn spreader valve adjusting knob (16) counter clockwise to

fully open.

6. Trigger gun on and adjust inlet air pressure (for

recommended gures see Chart 1 under Parts Replacement)

at the gun inlet. (Pressure gauge shown under Accessories is

recommended for this).

7. Turn uid adjusting knob (28) counter clockwise until rst

thread shows and turn on the supply air to the pressure cup.

8. Test spray. If the nish is too dry, reduce airow by reducing

air inlet pressure.

9. If nish is too wet, reduce uid ow by turning uid adjusting

knob (28) clockwise. If atomisation is too coarse, increase inlet

air pressure. If too ne, reduce inlet pressure.

10. The pattern size can be reduced by turning spreader valve

adjusting knob (16) clockwise.

11. Hold gun perpendicular to surface being sprayed. Arcing

or tilting may result in uneven coating.

12. The recommended spray distance is 150-200 mm (6"–8").

13. Spray edges rst. Overlap each stroke a minimum of 75%. Move

gun at a constant speed.

14. Always turn off air supply and relieve pressure when gun is not

in use.

PREVENTIVE MAINTENANCE & CLEANING

To clean air cap and uid nozzle, brush exterior with a stiff bristle

brush. If necessary to clean cap holes, use a broom straw or

toothpick if possible. If a wire or hard instrument is used, extreme

care must be used to prevent scratching or burring of the holes which

will cause a distorted spray pattern.

To clean uid passages, remove uid supply hose, then ush with a

suitable solvent. Wipe gun exterior with a solvent dampened cloth.

Never completely immerse in solvent as this is detrimental to the

lubricants and packings.

NOTE

When replacing the uid nozzle or uid needle, replace both

at the same time. Using worn parts can cause uid leakage.

See page 11, Chart 2. Also, replace the needle packing at this

time. Lightly lubricate the threads of the uid nozzle before

reassembling. Torque to 18–20 Nm (13–15 ft-lbs). Do not over

tighten the uid nozzle.

CAUTION

To prevent damage to uid nozzle (8) or uid needle (24), be

sure to either 1) pull the trigger and hold while tightening or

loosening the uid nozzle, or 2) remove uid adjusting knob (28)

to relieve spring pressure against needle collar.

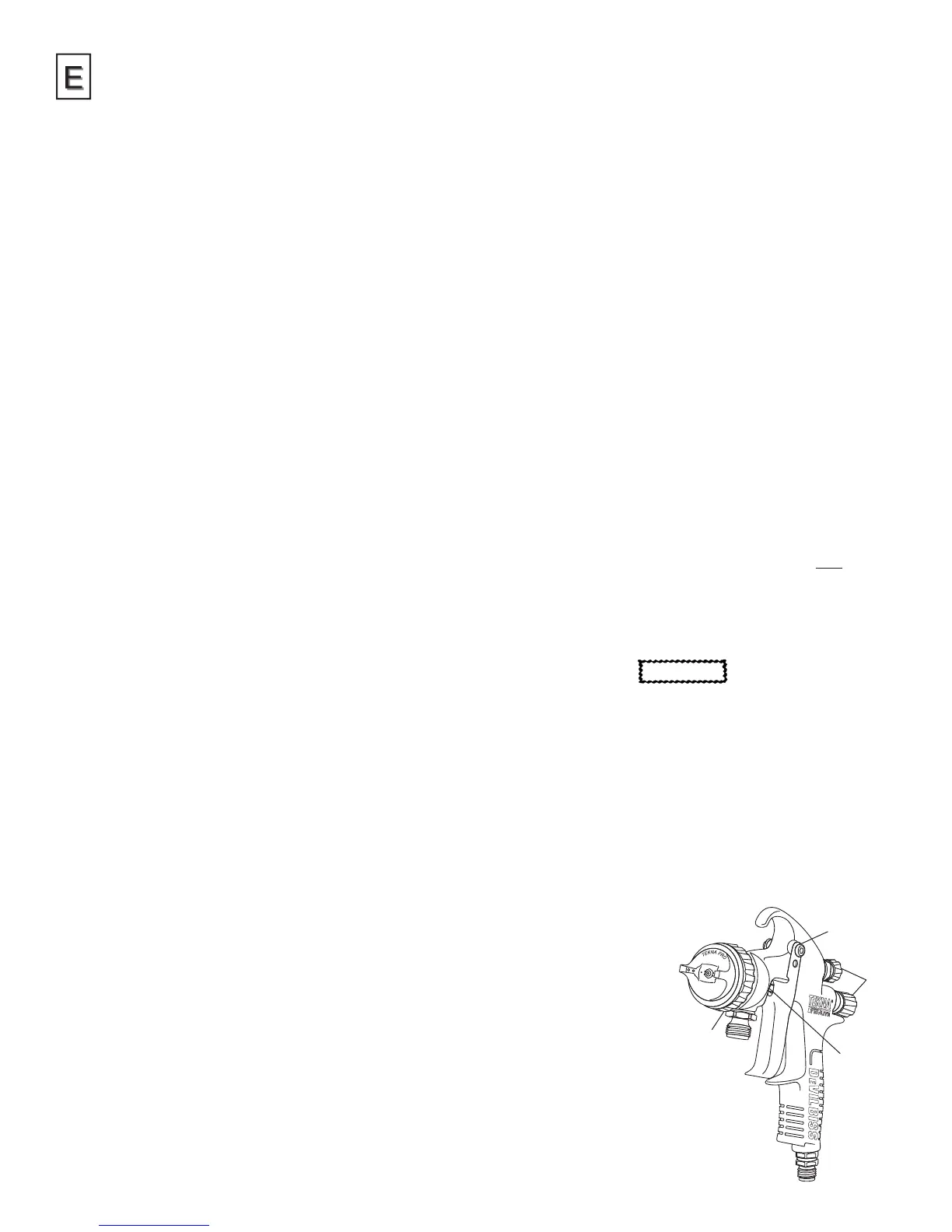

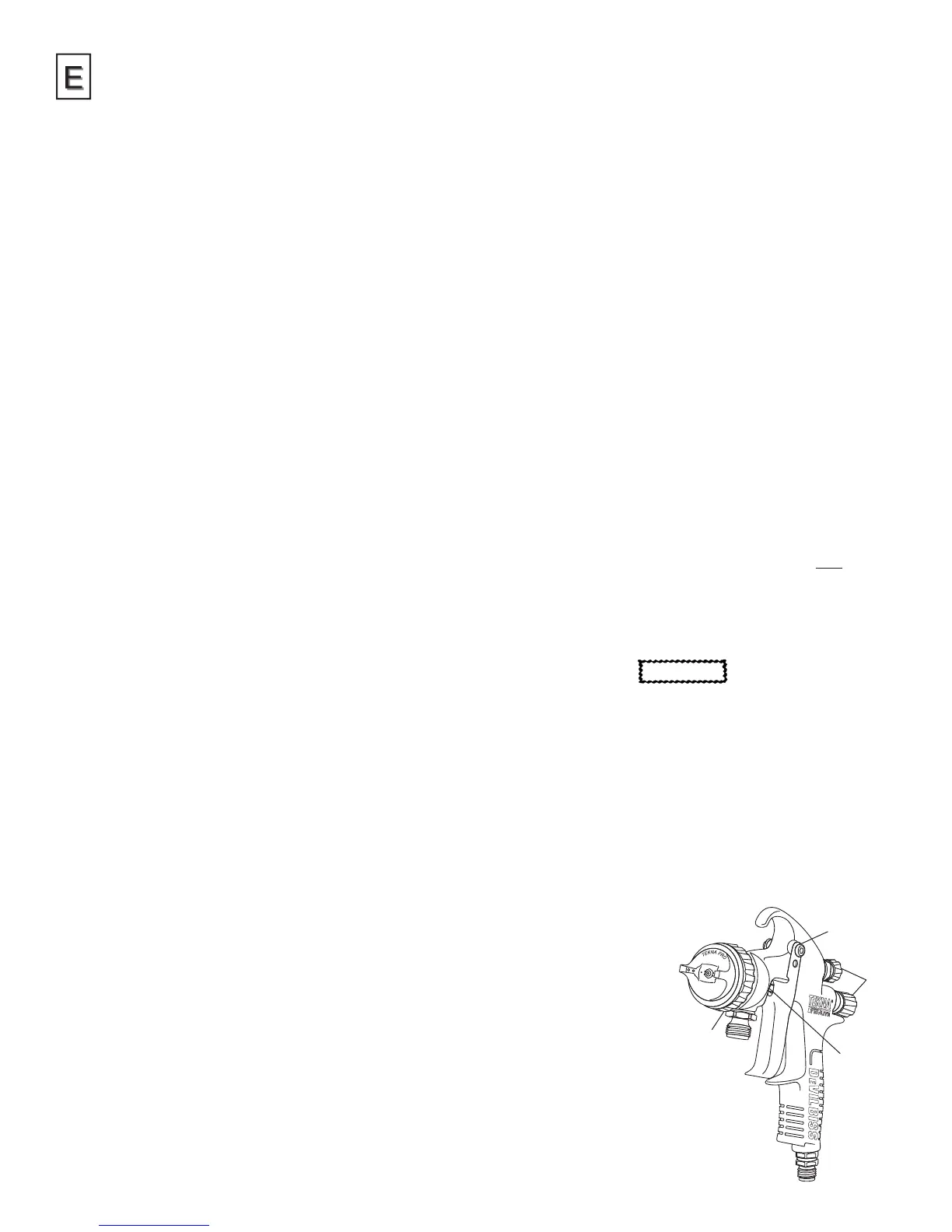

SPRAY GUN LUBRICATION

Daily, apply a drop of spray gun lubricant at trigger stud (40). The

shank of uid needle (24) where it enters packing nut (36) should

also be oiled. Fluid needle packing (34) should be lubricated

periodically. Make sure spray head (9) and air cap retaining ring (1)

threads are clean and free of foreign matter. Before assembling air

cap retaining ring to spray head, clean the threads thoroughly, then

add two drops of spray gun lubricant to threads. Fluid needle spring

(25) and air valve spring (21) should

be coated with a very light grease,

making sure that any excess grease

will not clog the air passages.

Points of Lubrication

A. Trigger Points

B. Packing

C. Adjusting Knobs

D. Air Cap Retaining Ring Threads

A

C

D

B

Loading...

Loading...