TB-1022

11

Parts Replacement/Maintenance

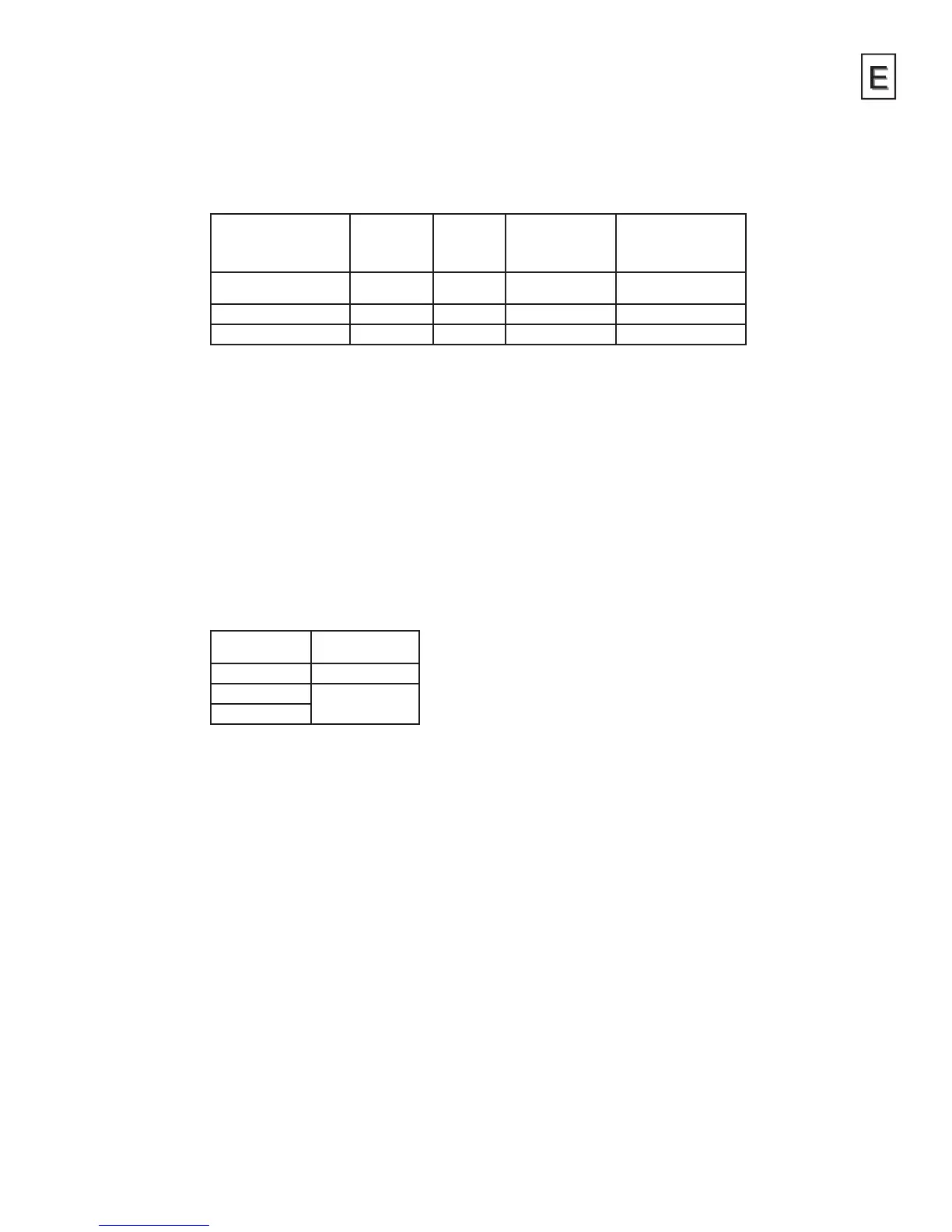

Chart 1 – Air Caps

ORDER NO. FOR

AIR CAP

TECHNOLOGY MARKING

ON AIR CAP

NOMINAL

OPERATING GUN

INLET PRESSURE

BAR/PSI

AIR FLOW

LPM/SCFM

PRO-103-HV40 HVLP HV40 (1.2) / 17

(for compliance)

(298) / 10.5

PRO-103-TE20 High Efciency TE20 (1.8 – 3.5) / 26 – 50 (340 – 550) / 12 – 19.4

PRO-103-TE40 High Efciency TE40 (2.0 – 3.5) / 29 – 50 (368 – 550) / 13 – 19.4

NOTE 1: Guns with HVLP caps must not exceed 0.7 bar (10 psi) air cap pressure with

gun fully triggered. (Aproximately 17 psi gun inlet pressure.) (See accessories

for air cap test kit which is available to set the exact cap pressure.)

When used with high efciency caps and Automotive Renishing materials,

these spray guns have been found to exceed 65% transfer efciency under

recommended conditions.

NOTE 2: When removing air cap from retaining ring, don’t remove slip ring (2)

or retaining ring seal (5) from retaining ring. Damage to the parts may

occur. Slip ring and retaining ring seal are not available as replacements.

Simply wipe parts clean and reassemble with new or clean air cap.

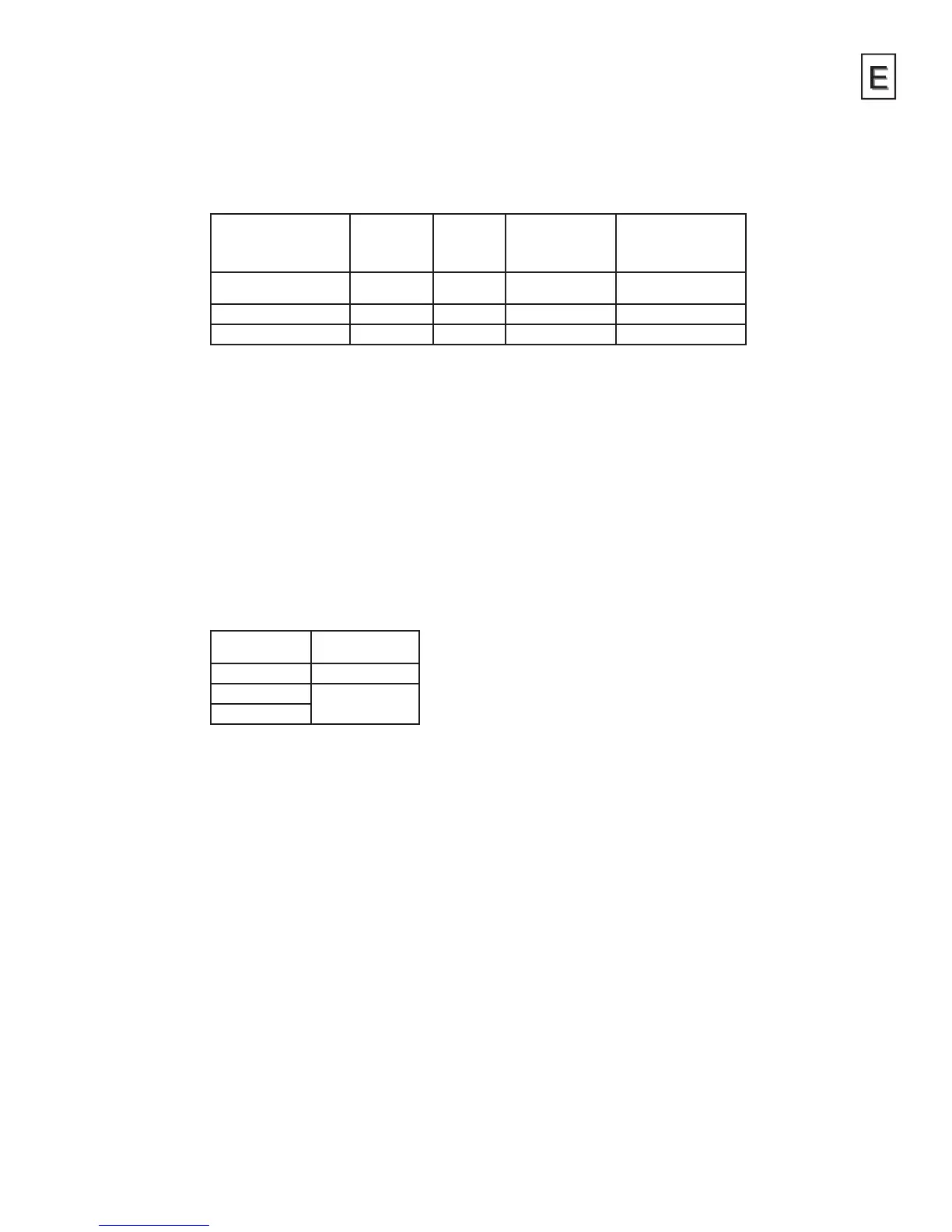

Chart 2 – Fluid Nozzles & Fluid Needles

PART NO. ON

FLUID NOZZLE

PART NO. ON

FLUID NEEDLE

PRO-205-10-K PRO-320-085-10K

PRO-205-12-K

PRO-320-12-14-K

PRO-205-14-K

NOTE: When replacing the uid nozzle or uid needle, replace both at the same time.

Lightly lubricate the threads of the uid nozzle before reassembling. Torque

to 18–20 Nm (13–15 ft-lbs). Don’t over tighten the uid nozzle. Use 10 mm

wrench supplied with gun.

Loading...

Loading...