- 23 -

0DT866 2016-01-25

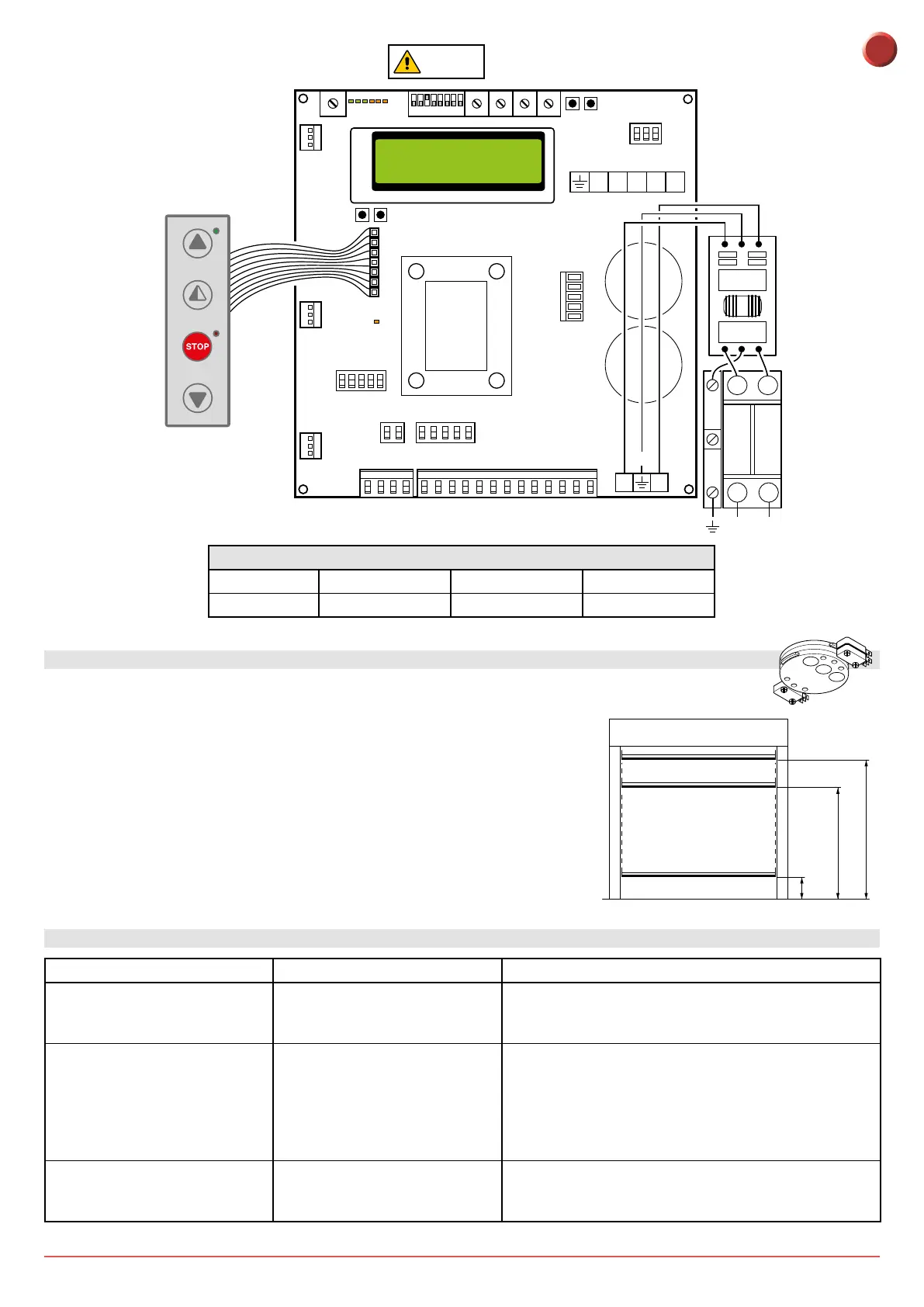

P5

P3 P4P1 P2

41 40 20 9 8 4 3 2 1 1 0 LAMP1 11 12 13

ON

OFF

1 2 3 4 5 6 7 8

DL

2

3

4 5

6 7

DL

M7

M4A

M5

M6

M3

BACK

M4

1 IN NC C NO

M2

J4

15

S3 S4

S5 S2

SAFETY OPEN

F2F1

230 V

GND

L N

+F -F U V W

ON

5. TROUBLESHOOTING

Display message Problem Check

Current limit exceeded Requested motor torque

exceeds available torque.

• Reduce opening speed.

• Check power supply.

• Check power supply wiring.

Insert brake resistance Voltage on BUS exceeds

threshold

• For Sector Reset doors, connect the brake resistance

and set the item on the advanced menu to "YES".

• Switch off the control panel, wait 3 minutes and

reconnect the power supply.

• If the error reoccurs, check that the voltage on the

BUS is lower than 360 V.

Max. BUS voltage BUS voltage exceeds threshold • Switch off the control panel, wait 3 minutes and

reconnect the power supply.

• Check the control panel power supply voltage.

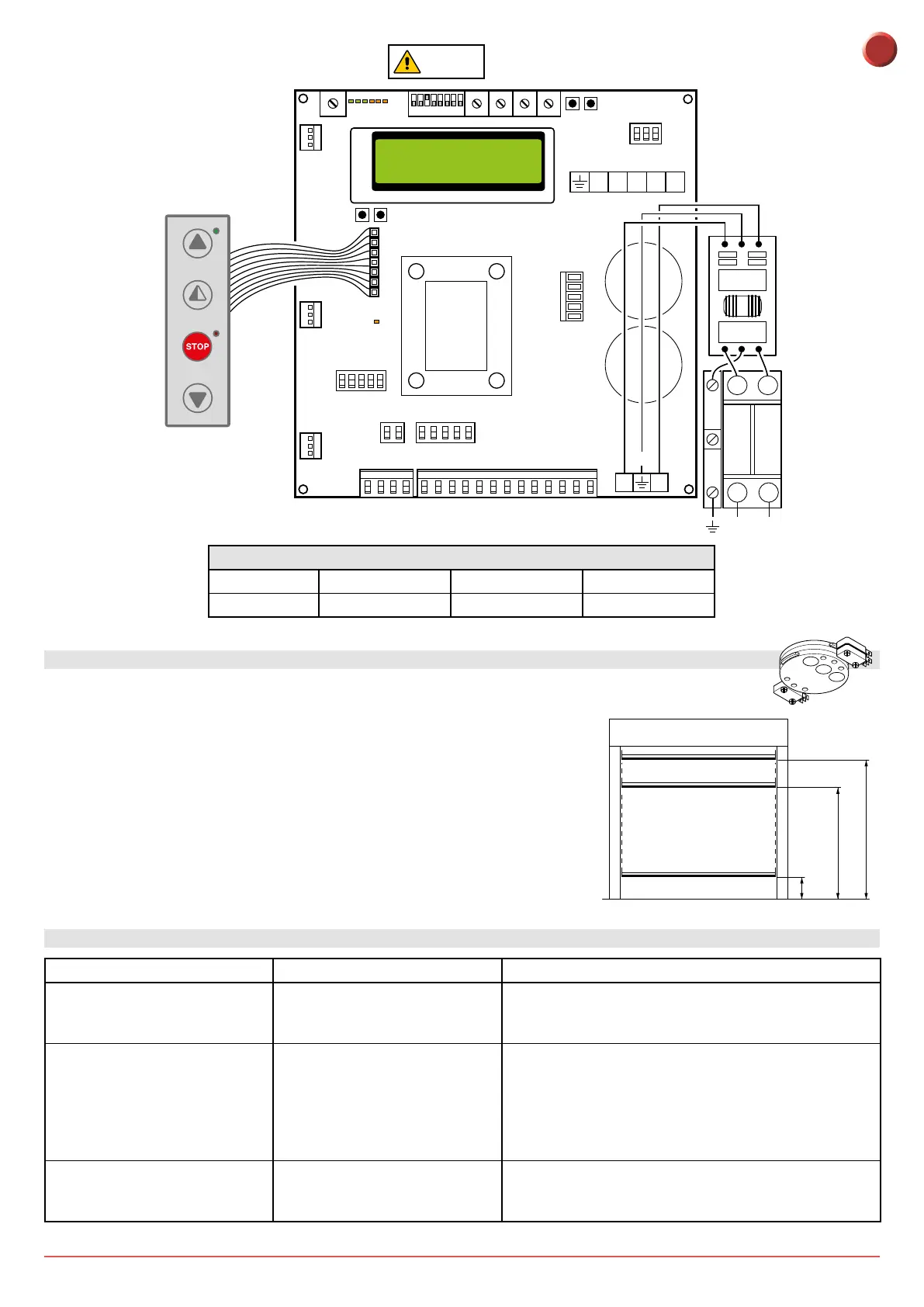

4. LIMIT SWITCH ADJUSTMENT

1. Set the deceleration ramps at zero (P3 - P4)

2. Set the limit switch (C) on the gearmotor so that the door stops about

200/300mm from its closure point.

3. Set the opening limit switch (A) at the opening point.

4. Set the deceleration limit switch (B) so it is triggered at about ¾ of the

opening stroke.

5. Set the opening and closure speeds using trimmers (P1) and (P2) respectively.

6. Set the trimmers of the deceleration ramps - (P3) for opening and (P4) for

closure - to ensure the door stops at its actual "open" and "closed" positions.

C

B

A

B

C

300

A

¾

Dip 3 ON

FUSES

ID Value Size Circuit

F1 - F2 12A - 500V 10.3 x 38 Single phase line

EN

Loading...

Loading...