11.2. Centrifuge tube

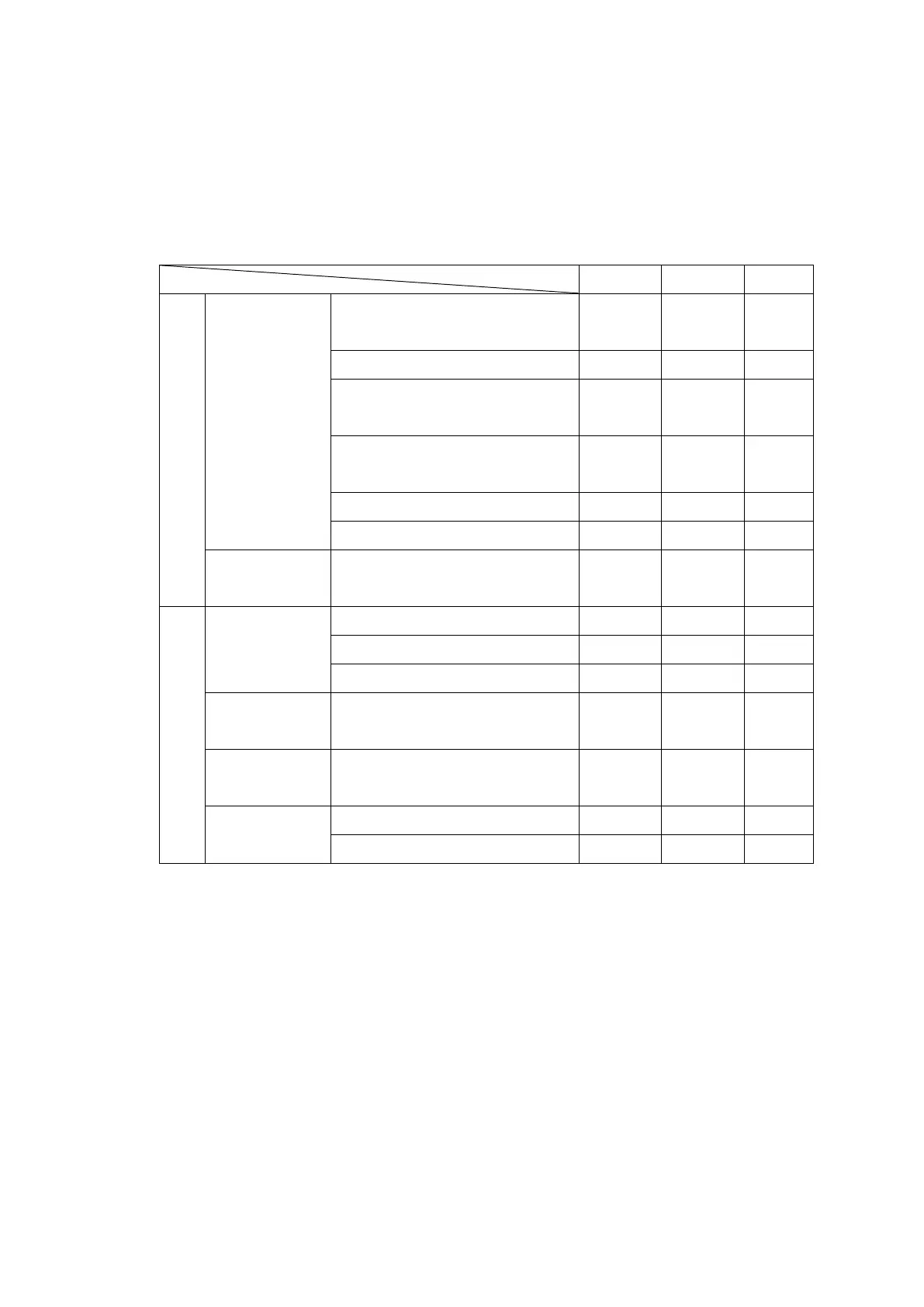

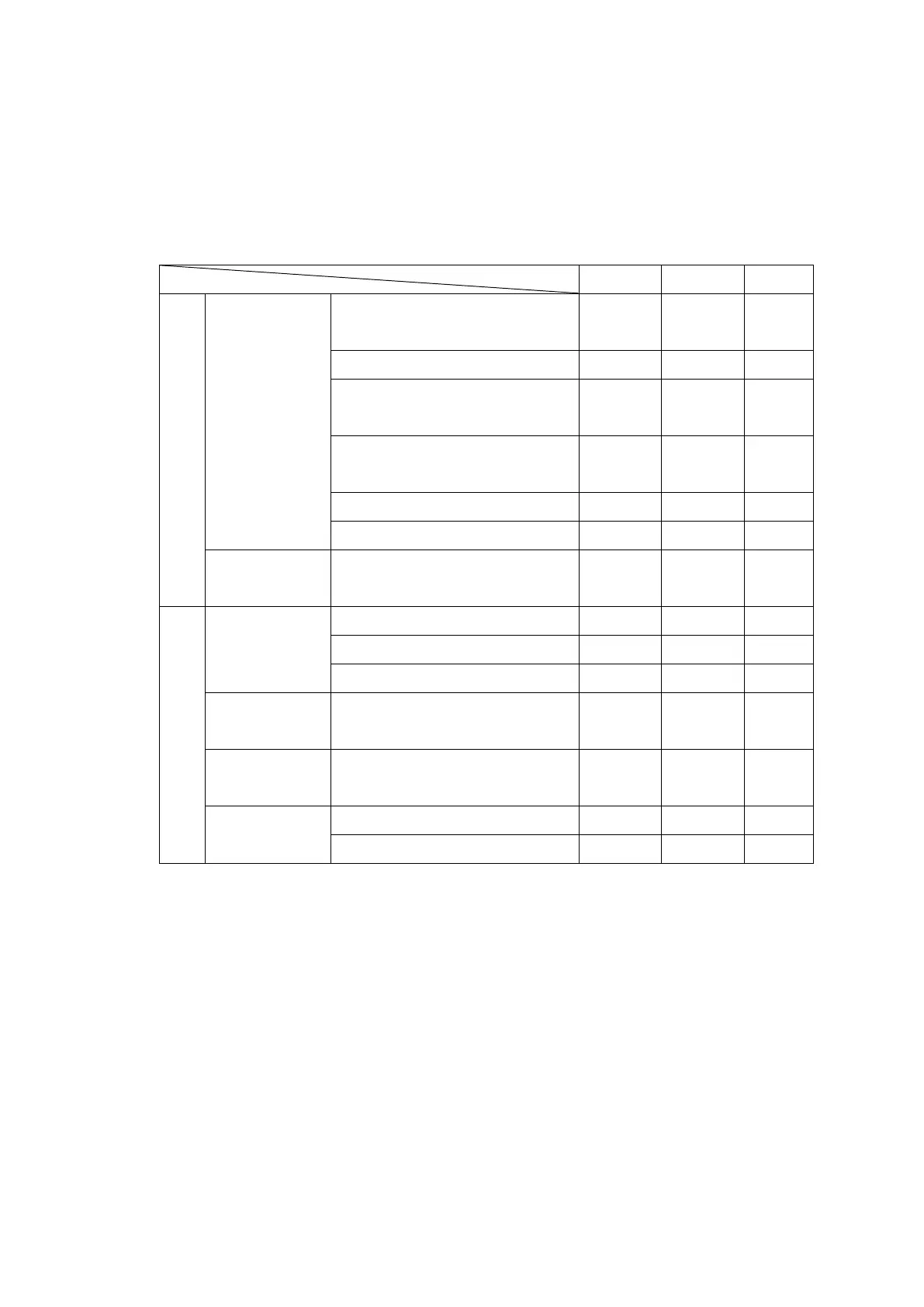

11.2.1. Please clean and sterilize the centrifuge tube by reference to the following table.

Table 11.2 Conditions for cleaning and sterilization of centrifuge tube O: Yes X: No

PA: polyallomer PC: polycarbonate PP: polypropylene

11.2.2. PC centrifuge tube cleaning

PC material has relatively low chemical stability to alkaline solvent, therefore use of cleaning agent

with pH value of over 9 should be avoided. Some neutral cleaning agents still have pH value of over 9

after being diluted as recommended by the vendor, therefore use of cleaning agent with pH value of 7-9

only is recommended.

11.2.3. Autoclaving of PA, PC and PP centrifuge tube

PA begins softening at the temperature of 120℃, while PC and PP begin softening at 130℃.

Generally, PA may be sterilized for 30 min at 115℃(0.7 kg/cm

2

), while PC and PP may be sterilized

Loading...

Loading...