G643(E) Service Manual Chapter 4. Engine Electrical System 113

Ignition System Control

Spark-ignited engines require accurate control of

spark timing and spark energy for efficient

combustion. The MI-07 ignition system provides this

control. The system consists of the following

components:

• SECM

• Distributer with ignition module *

• Ignition coil(s) *

• Crankshaft position sensor *

• Crankshaft timing wheel *

• Spark plugs *

(*) Customer-supplied components

The SECM, through use of embedded control

algorithms and calibration variables, determines the

proper time to start energizing the coil and fire the

spark plug. This requires accurate crank/camshaft

position information, an engine speed calculation,

coil energy information, and target spark timing. The

SECM provides a TTL compatible signal for spark

control. The coil must contain the driver circuitry

necessary to energize the primary spark coil

otherwise an intermediary coil driver device must be

provided. The SECM controls spark energy (dwell

time) and spark discharge timing.

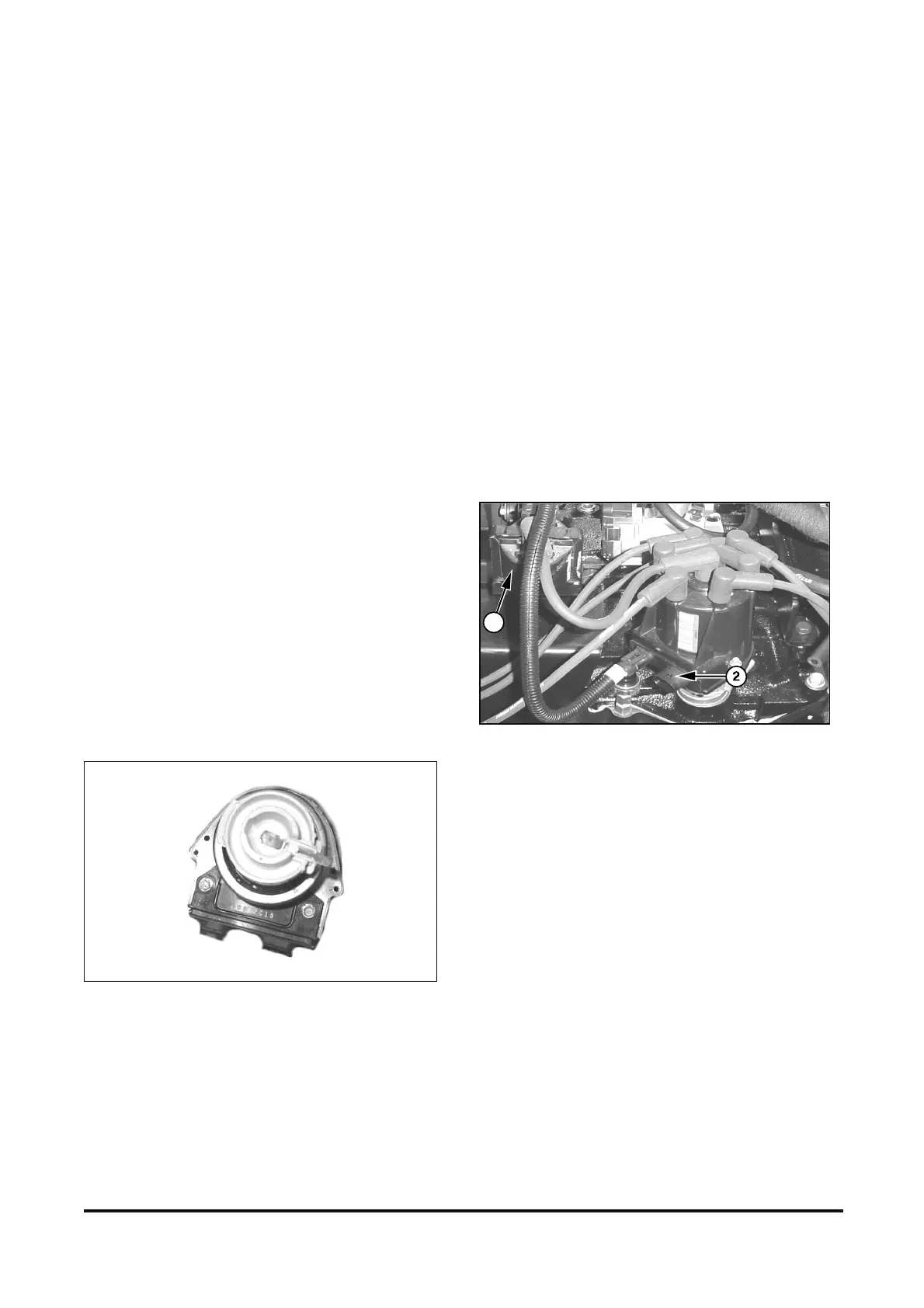

Figure 14. GM Distributor

The MI-07 system is capable of operating with either

a distributor based ignition system or a

distributorless ignition system. The current

application uses a distributor based ignition system.

The distributor will have no internal advance

mechanisms giving the SECM consistent authority

over ignition timing. The spark is sent to the

appropriate cylinder in the conventional way via the

rotor arm and spark plug wires. The SECM uses the

signal from the GM (General Motors) Delco Ignition

Module to determine the engine position and RPM

at any time. It uses this information together with the

information from the TPS sensor and TMAP to

calculate the appropriate ignition timing settings.

The General Motors (GM) distributor (Figure 14)

used in the Delco EST ignition system, incorporates

a Variable Reluctance (VR) sensor, which transmits

a reference signal to the GM ignition module (Figure

15) located on the distributor. A variable reluctance

sensor is an electromagnetic device consisting of a

permanent magnet surrounded by a winding of wire.

The sensor is used in conjunction with a ferrous

signal rotor on the distributor shaft. The signal rotor

has six lobes, one for each cylinder. Rotation of the

signal rotor near the tip of the sensor changes the

magnetic flux, creating an analog voltage signal in

the sensor coil.

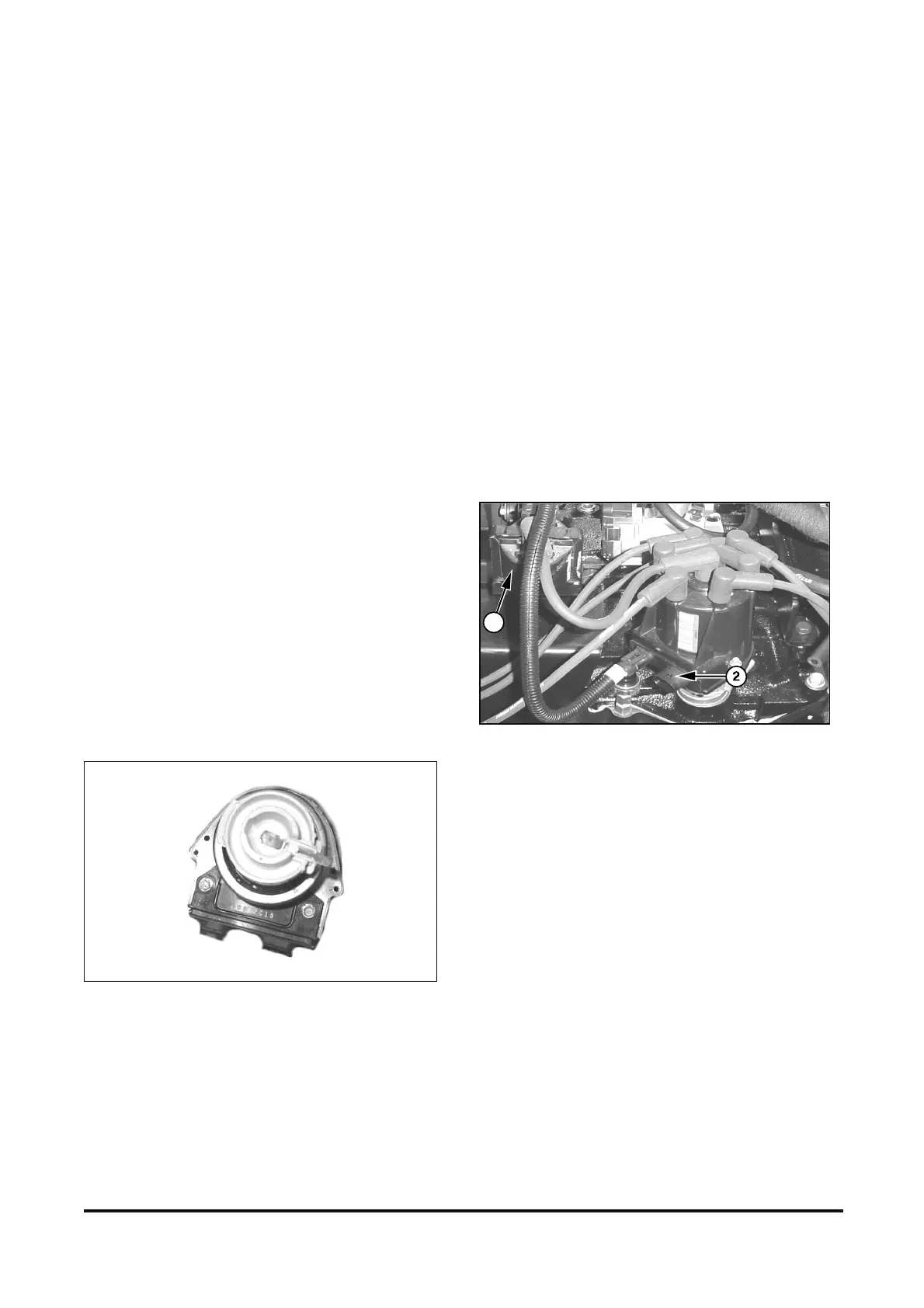

(1) lgnition Coil. (2) lgnition Module.

Figure 15. GM Ignition Module

The rising edge of the VR signal is converted to a

rising 5-volt signal by the ignition module. As the VR

signal passes back through zero volts, a falling edge

is created producing a square wave or digital signal,

similar to the signal produced by a Hall effect sensor.

This falling edge signal provides a stable engine

position reference at all engine speeds for the

SECM.

1

Loading...

Loading...