G643(E) Service Manual Chapter 6. LPG FUEL DELIVERY SYSTEM 217

Power Valve Adjustment

1. The power valve should only be adjusted after the

idle screw has been adjusted properly. The

engine and vehicle drive train and hydraulics

should also be at normal operating temperatures.

2. Apply a load to the engine while the engine is

operating above idle speed. Torque converter stall

is the preferred operating mode for this test. If a

torque converter speed test cannot be performed,

the engine can be run at another speed (max

governor), but a load must be applied by using

hydraulics.

NOTE : While adjusting the power valve, do not hold

engine at load point for longer than 5-10 seconds.

Holding for a longer period of time will cause the fuel

temperature to drop, which could adversely affect

the power valve setting.

3. Monitor the output of the UEGO or HEGO sensor

while the engine is at the higher speed with the

load applied (phi = 1.00 to 1.05 is optimal).

4. If the phi reading is not at the desired level, bring

the engine back to idle and adjust the power valve.

5. Bring the engine back to the higher speed with a

load applied and verify the power valve setting.

Adjust further as needed.

6. Once the power valve is set, bring the engine

back to idle and verify the idle screw setting.

G643 LP Fuel Systems Without O2 Sensor

Idle Adjustment

1. After the mixer is installed, start and warm up the

engine to normal operating temperature

(ECT>167°F [75°C]). Also ensure that the vehicle

drive train and hydraulic systems are at normal

operating temperatures per vehicle manufacturer

recommendations.

2. Allow the engine to reach steady state at idle.

3. With the idle screw completely tightened

clockwise, use a standard screwdriver to adjust

the idle screw counterclockwise until a minimum

average MAP value has been reached. The MAP

value is displayed on the Service Tool screen.

Power Valve Adjustment

1. The power valve should only be adjusted after the

idle screw has been adjusted properly. The

engine and vehicle drive train and hydraulics

should also be at normal operating temperatures.

2. Apply a load to the engine while the engine is

operating above idle speed. Torque converter stall

is the preferred operating mode for this test. If a

torque converter speed test cannot be performed,

the engine can be run at another speed (max

governor), but a load must be applied by using

hydraulics.

The power valve should be adjusted to obtain

maximum torque converter stall speed.

NOTE : While adjusting the power valve, do not hold

engine at load point for longer than 5-10 seconds.

Holding for a longer period of time will cause the fuel

temperature to drop, which could adversely affect

the power valve setting.

3. Once the power valve is set, bring the engine

back to idle and verify the idle screw setting.

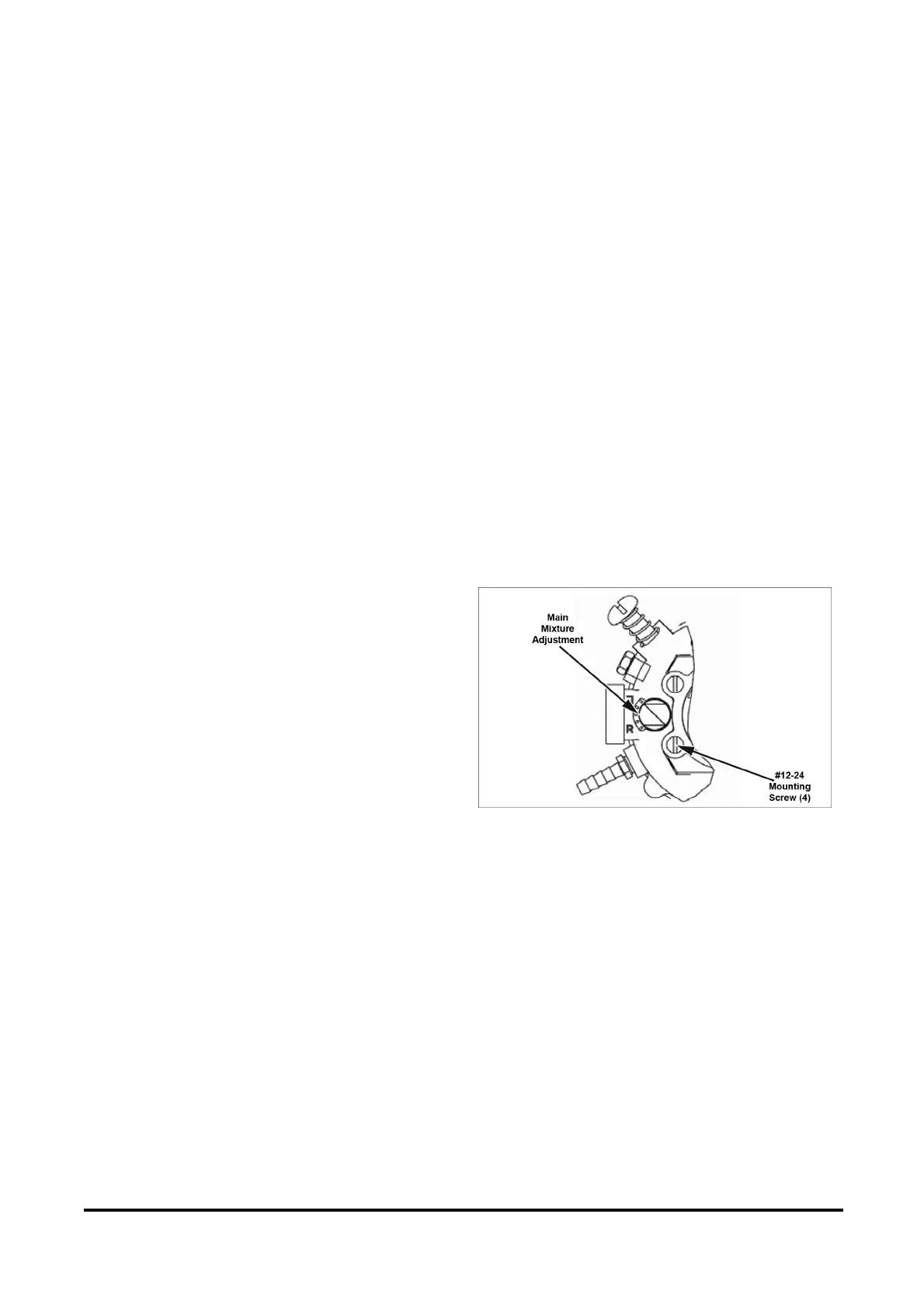

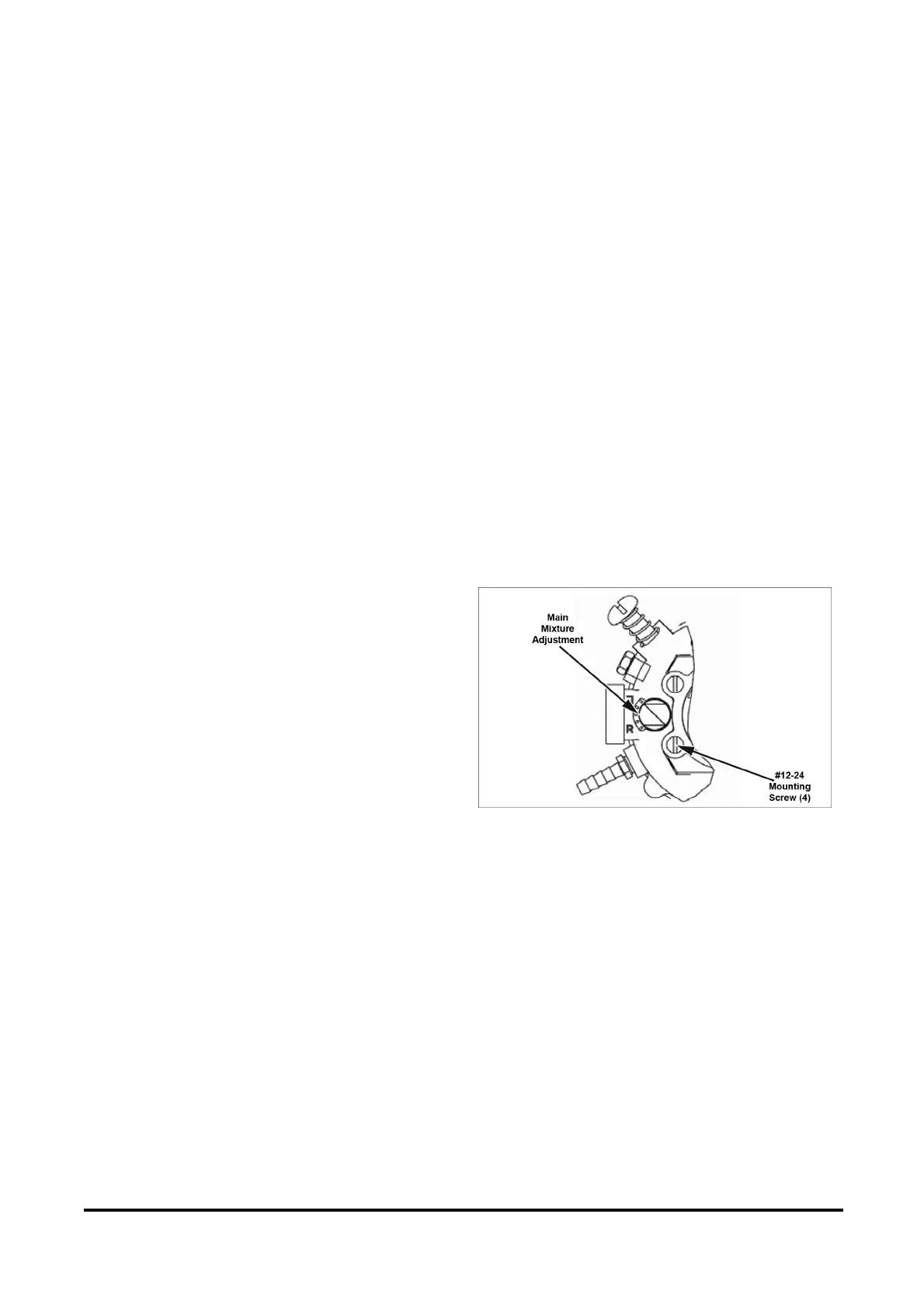

Figure 43. Main Mixture Adjustment on Bottom of

Mixer (partial view)

Loading...

Loading...