To Free a Jammed Flywheel

SHUT DOWN THE ENGINE, WAIT FOR ALL MOVING PARTS TO COME TO A COMPLETE STOP,

REMO TTERY CABLE, THEN WAIT 5

MINU

VE SPARK PLUG WIRE, DISCONNECT THE NEGATIVE BA

TES BEFORE MOVING OR WORKING ON THE CHIPPER.

28 16.50 PRO DR

®

RAPID-FEED™ CHIPPER

2" Wrenches

Tools Needed:

• Two 1/

Dis ssemble:a

Disconnect the battery at the n1. egative terminal.

pper.

es and then remove the Discharge

Chute (Figure 23).

4. Check to see if the Discharge Chute or Discharge

opening is clogged. If it is, clear it with a branch.

5. With a wooden stick, loosen and remove any material

left in the Chipping Chamber and make sure the

Flywheel turns freely with the stick.

Reassemble:

2. Remove any material left in the Chipper Ho

NEVER PRY AGAINST THE SCROLL WELDMENT WHEN REMOVING THE DEFLECTOR OR DISCHARGE

CHUTE, OR AT ANY OTHER TIME. THIS WILL CAUSE DAMAGE TO THE MACHINE.

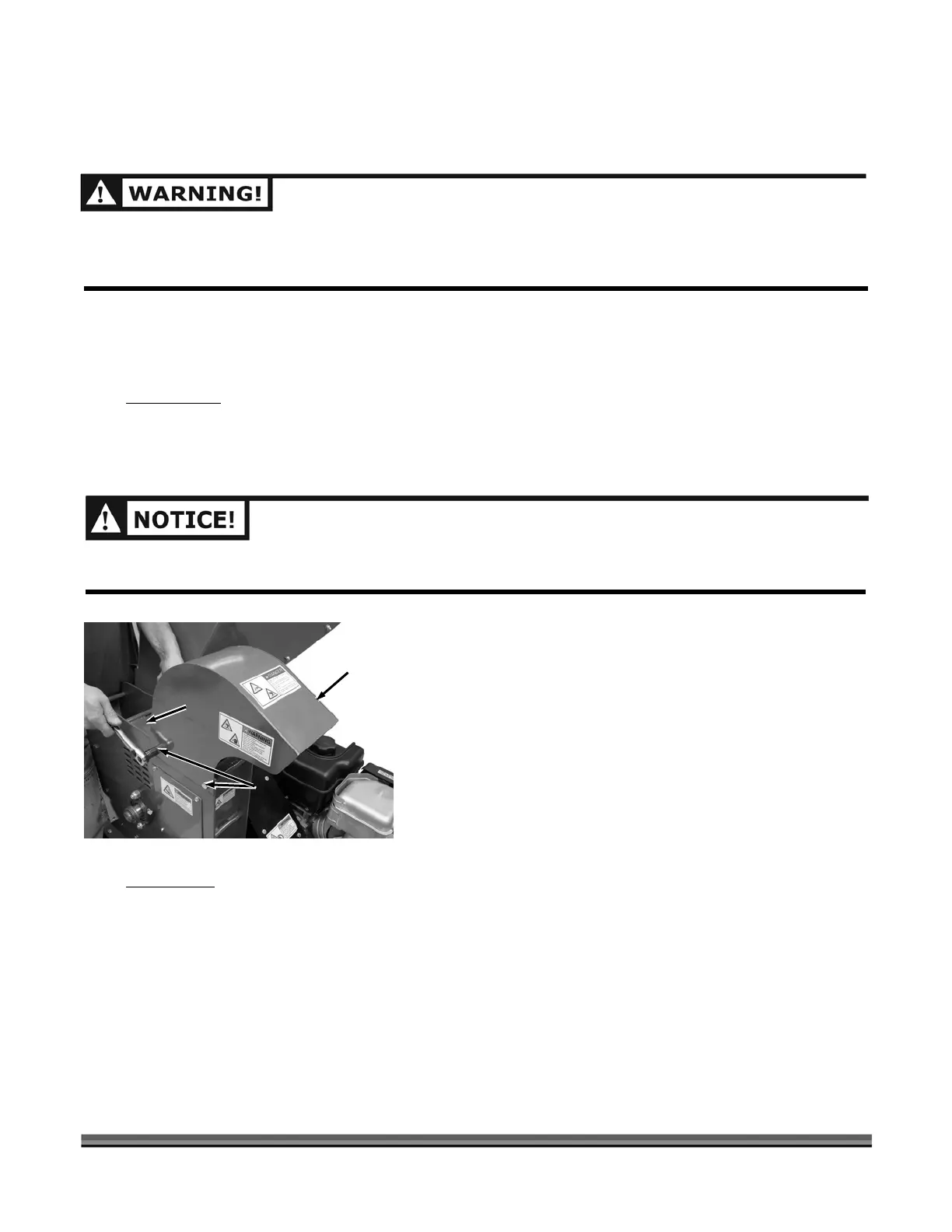

3. Remove the two Bolts and Locknuts that secure

Discharge Chute to the Chipper Basic Asse

two 1/2" wrench

the

mbly with

1. Position the Discharge Chute onto the Chipper Basic Assembly and secure with two Bolts and

Locknuts using two 1/2" wrenches.

2. Reconnect the battery negative terminal cable, the spark plug wire and start the Chipper engine;

allowing the remaining material in the Chipping Chamber to discharge.

3. If the Chipping Chamber doesn’t clear and the flywheel is still jammed, repeat above process.

NOTE: Be certain the Chipping Chamber is clear before trying to process more material into the Chipper

Hopper.

Fi

ure 23

Discharge

Chute

Bolts and

Locknuts

Scroll

Weldment

Loading...

Loading...