CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 41

have pressed in Bearings

for easy trans owing procedures will

explain the replacement pr

Tools Needed:

•

•

• Jack

1.

2. Loosen

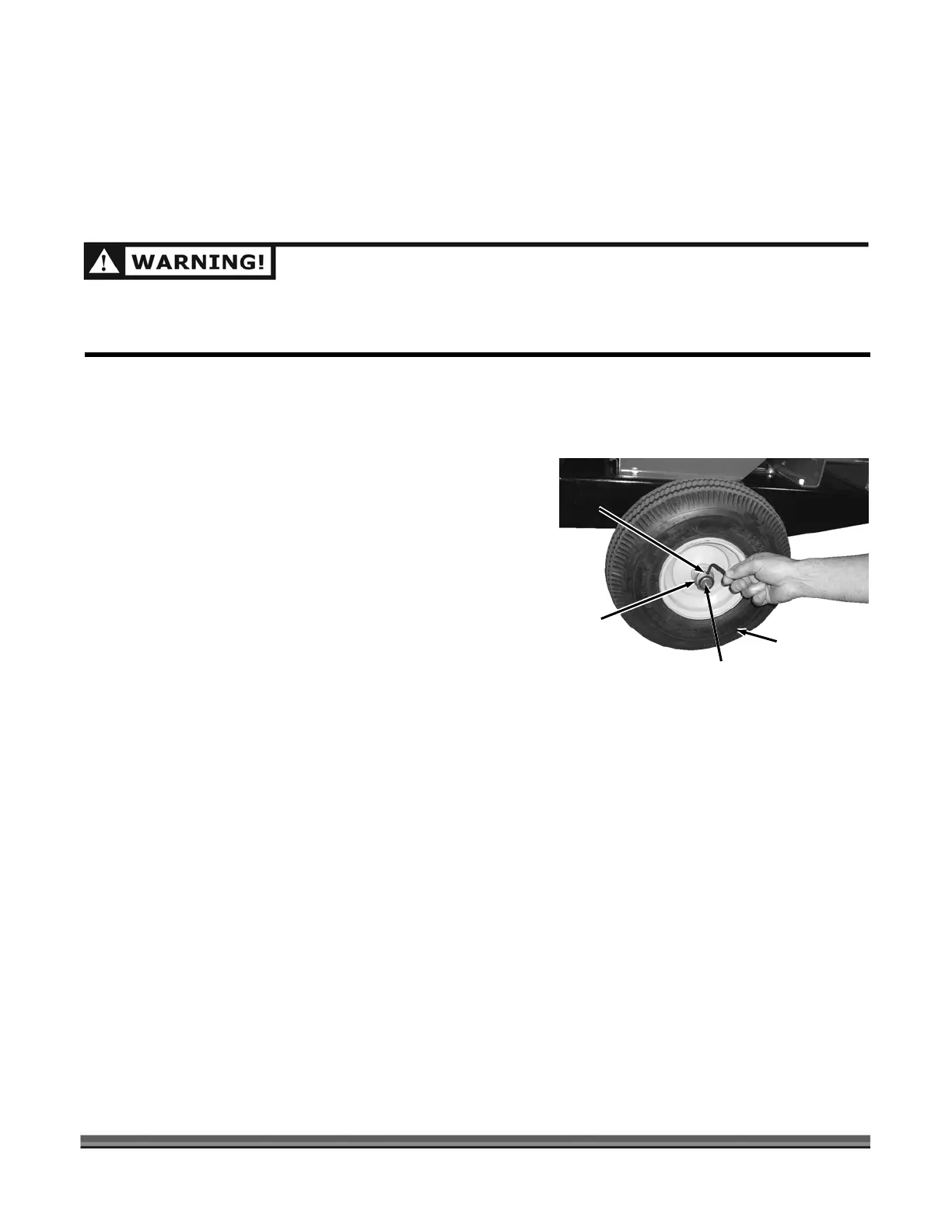

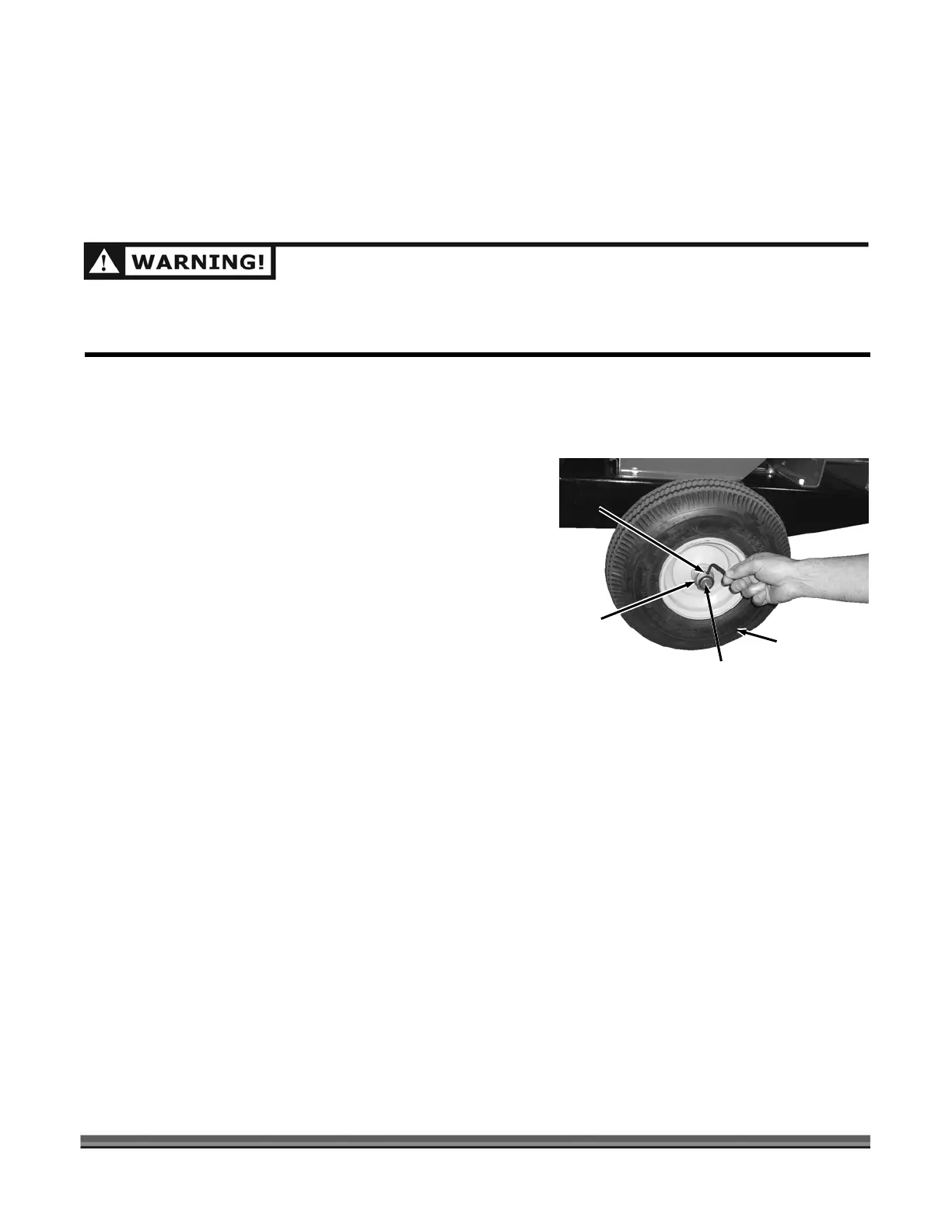

remove the Locking Collar (Figure 45

NO

NO

4. matic Wheel onto the Axle and against

5. ten the Set Screw with a 5/32"

Allen Wrench.

6. Check the Pneumatic Wheels for proper air pressure of 38 psi maximum in each tire (see Chapter

3).

Removing and Replacing the Clutch

The design of the Clutch on your machine is for rugg it is important to

understand the limitations of a Clutch. The Clut e,

and slip er excessive g of the drive

Engine from damages such as broken crankshafts an

are normal wear items. If you notice decre

essary.

SHUT DOWN THE ENG OR ALL M RTS

REMOVE SPARK PLUG WIRE, DISCONNECT THE NEGATIVE BA

BEFORE PERFORMING ANY MAINTENANCE PROCEDURE OR INSPECTION ON THE CHIPPER.

Removing and Replacing the Wheels

The Wheels on the DR 16.50 FTP PRO Rapid Feed Chipper are pneumatic and

port. With use, tires or Bearings may need replacing. The foll

ocedures.

5/32" allen wrench

Fine Tooth File

Jack up the side of the Chipper just until the

Pneumatic Wheel is off the ground.

the Set Screw with a 5/32" allen wrench and

INE, WAIT F OVING PA TO COME TO A COMPLETE STOP,

TTERY CABLE, THEN WAIT 5 MINUTES

Pneumatic

Figure 45

Collar

Set Screw

).

3. Remove the Pneumatic Wheel from the Axle.

TE: There is a spacer behind the wheel that must remain

on the Axle when the Pneumatic Wheel is replaced.

TE: File off the Set Screw marks in the Axle if Wheel will

not slide on.

Install the Pneu

the Spacer with the Valve side out.

Install the Locking Collar onto the Axle against the Wheel and tigh

ed, dependable service; however,

ch design is to provide load free starting of the Engin

n application. These features help protect the page und overloadin

d starters. The Shoes and Springs on the Clutch

ased performance of the Clutch, check and replace it if

nec

Wheel

Locking

Axle

Loading...

Loading...