Calibration | en

Instructions for use | Dräger PointGard 2000 Series 17

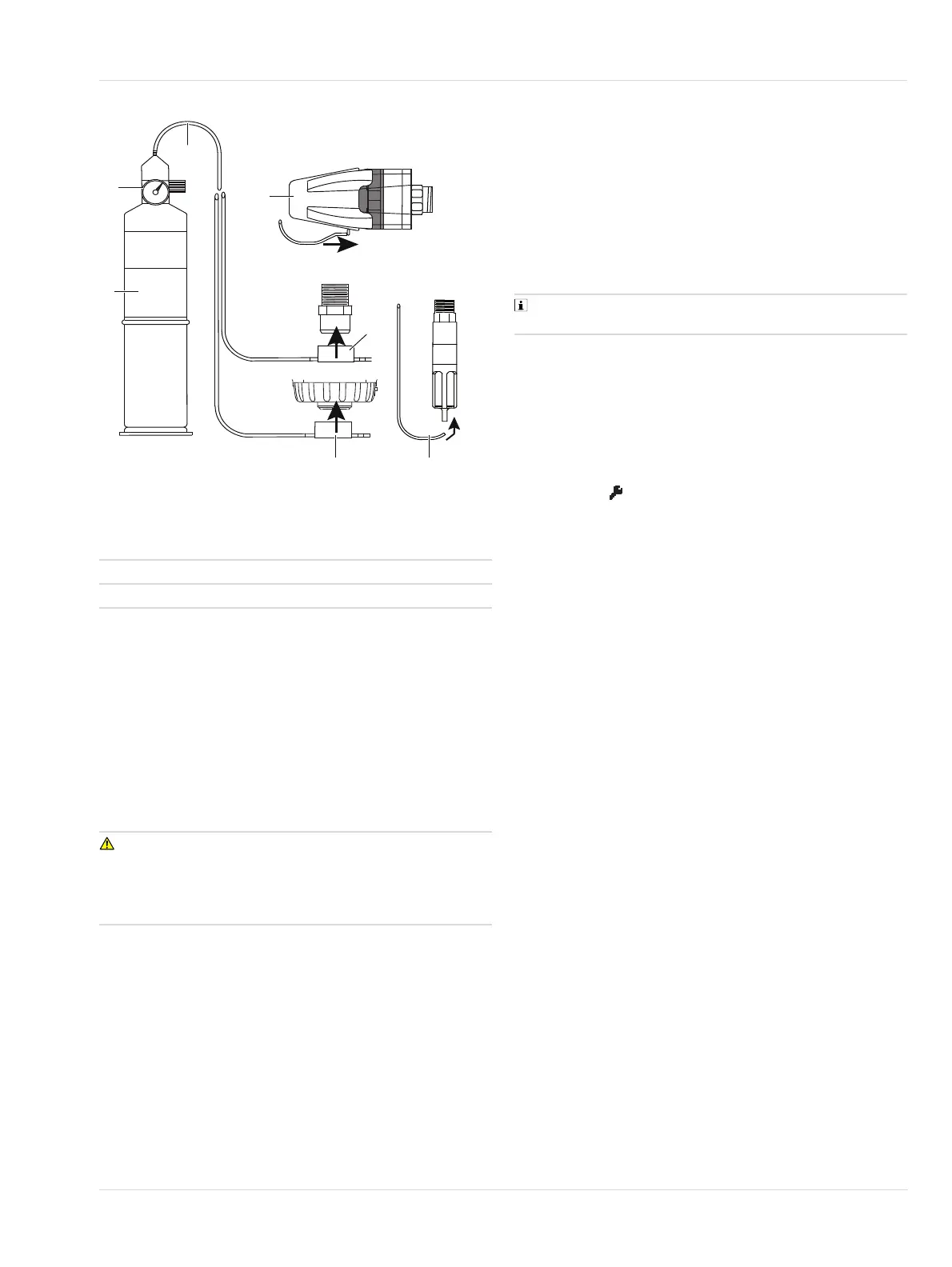

8.3 Gas flow for calibrations

Gas flow varies depending on the sensor.

Gas flow should correspond to the environmental conditions

during operation (e. g. duct measurement with higher flows

than 2 l/min)

8.4 Zero calibration

Ambient air can be used to zero the sensor instead of

Nitrogen or Synthetic Air only if the area is known to be free of

the target gas or any gas to which the sensor may be cross-

sensitive (as listed on the sensor data sheet). In this case, no

cylinder or calibration adapter is needed for the zero

calibration.

WARNING

Calibration fault at zero calibration

Insufficient ambient air flow may cause calibration errors.

► Make sure that the ambient air flow to the sensor is

sufficient.

PointGard 2100 EC-specific:

For Oxygen (O

2) sensors a zero calibration does not change

any value in the firmware or sensor. Thus, the zero calibration

function can be used to check the correct zero reading when

Nitrogen is applied to the sensor. The PointGard 2100 EC will

indicate a fault state if a zero check fails with a deviation of

more than 0.6 Vol% O

2 from zero. In case of a fault, repeat

the zero check or change the sensor if necessary. Use

Nitrogen (N

2) for verification.

PointGard 2200 CAT-specific:

Sensors must not be calibrated with pure nitrogen. Catalytic

sensors need oxygen to work properly.

PointGard 27x0 IR-specific:

For PointGard 2720 IR (with PIR 7200 to detect carbon

dioxide), only Nitrogen or Synthetic Air without any CO2

content may be used for a zero calibration.

8.4.1 Performing zero calibration

Calibration can be aborted at any time. To abort calibration

select back.

Prerequisites:

– Sensor has finished the warm-up phase

– Calibration is prepared.

Perform zero calibration

1. Select Calibration > Zero calibration and confirm.

The Maintenance signal is transmitted by the analog

interface, no alarm or fault relays are switched and the

symbol is displayed.

The message Apply zero gas is displayed.

2. Apply synthetic air or nitrogen, if ambient air cannot be

used.

a. Set gas flow corresponding to the sensor used (see

"Gas flow for calibrations", page 17)

3. Select Next and confirm.

The current value is displayed.

After the test gas has been applied to the sensor for 3

minutes and the displayed value is stable perform

calibration.

4. Select calibrate and confirm.

The message please wait... is displayed.

The new current value is displayed.

5. Select Next and confirm.

6. Turn off gas flow and remove the calibration adapter from

the sensor or disconnect tubing.

If the current value is not within the alarm range:

7. Select Next and confirm.

The instrument returns to the calibration menu.

8.5 Span calibration

PointGard 2200 CAT / 2200 CAT Remote IR / 2700 IR -

specific:

The span calibration has to be performed within 24 h after the

last valid zero calibration.

PointGard 2200 CAT Remote with IR sensor:

Due to the design of the DSIR gas sensor, the output signal of

the gas sensor is limited to 45 % . . . 55 % of the instrument-

internal supply voltage. If the gas concentrations increase

further after the maximum sensor output signal has been

reached, this does not lead to an increase of the values

displayed on the instrument response transmitted to the

35153

EC sensor 0.5 l/min ± 10%

All other sensors 0.5 l/min - 2 l/min

7

PIR 7x00

EC

DSIR

CAT Ex

1

3

4

3

2

2

5

Loading...

Loading...