24 Instructions for use | Dräger PointGard 2000 Series

en | Interface settings

DIP switch default settings for amber/red strobe

combination

DIP switch default settings for green/red strobe

combination

12.1.1 Setting the DIP switch pins

1. Open the instrument.

2. Toggle the DIP switch pins:

3. Close the instrument.

4. Commission the instrument.

13 Interface settings

13.1 4-20mA interface

The current output of the instrument during normal operation

is between 4 and 20 mA and is proportional to the detected

gas concentration.

PointGard 2xx0 uses different current values to indicate

various modes of operation. The factory default settings are

user adjustable for application specific requirements. This

follows the NAMUR recommendation NE43.

13.1.1 Full scale deflection

PointGard 2100 EC, 27x0 IR and 2200 CAT Remote LC only

Some sensors offer an adjustable full scale deflection to limit

the measuring range for the 4-20 mA interface.

The full scale deflection (FSD) sets an endpoint within the

measuring range of the sensor. If the gas concentration

reaches this endpoint, the 4-20mA interface transmits 20mA.

Example: Required range 0 to 500 ppm CO (e.g. part number

6809605 default 300 ppm, range min/max = 50/1000

ppm).Select full scale deflection as 500 ppm. The analog

output will be linear between 4 mA = 0 ppm and 20 mA = 500

ppm.

13.1.2 Setting fault current

This function defines the current for the fault signal.

1. Select Settings > Communication > Analog interface

>Fault current and confirm.

2. Select the line for editing the current and confirm.

3. Set the current and confirm.

The setting for the Fault current is displayed.

4. Select Confirm and confirm with [OK].

13.1.3 Information regarding the warning signal

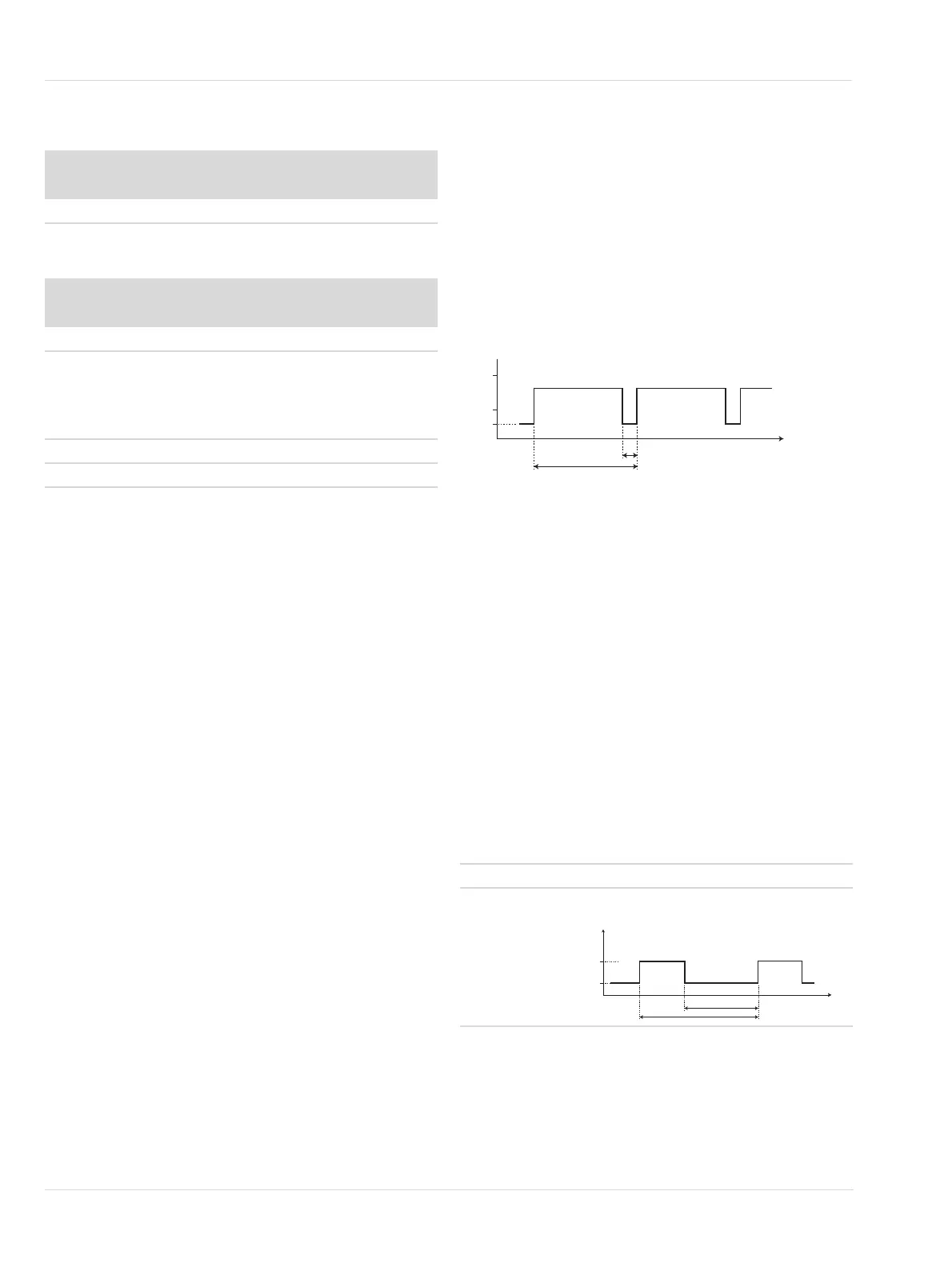

To transmit a warning signal via the analog interface, the

warning signal must be switched on.

The warning signal alternates between the warning current

and the measurement current.

– Warning current (interval T2)

– Measurement current (interval T1-T2)

Time intervals and the warning current are configurable.

13.1.4 Switching the warning signal on or off

1. Select Settings > Communication > Analog interface >

Warning and confirm.

2. Select Enable or Disable and confirm.

13.1.5 Setting warning interval

1. Select Settings > Communication > Analog interface >

Warning interval and confirm.

2. Set times for warning intervals T1 and T2 and confirm.

13.1.6 Setting warning current

1. Select Settings > Communication > Analog interface >

Warning current and confirm.

2. Set the current and confirm with [OK].

13.1.7 Setting maintenance signal

1. Select Settings > Communication > Analog interface >

Maint. signal and confirm.

2. Set the signal type and confirm.

13.1.8 Setting static maintenance current

The maintenance current can only be set if the maintenance

signal has been set to static.

1. Select Settings > Communication > Analog interface

>Maint. current and confirm.

Pins

1 2 3 4 5

ON OFF OFF ON OFF

Pins

1 2 3 4 5

ON OFF ON ON OFF

to the left ON

to the right OFF

35869

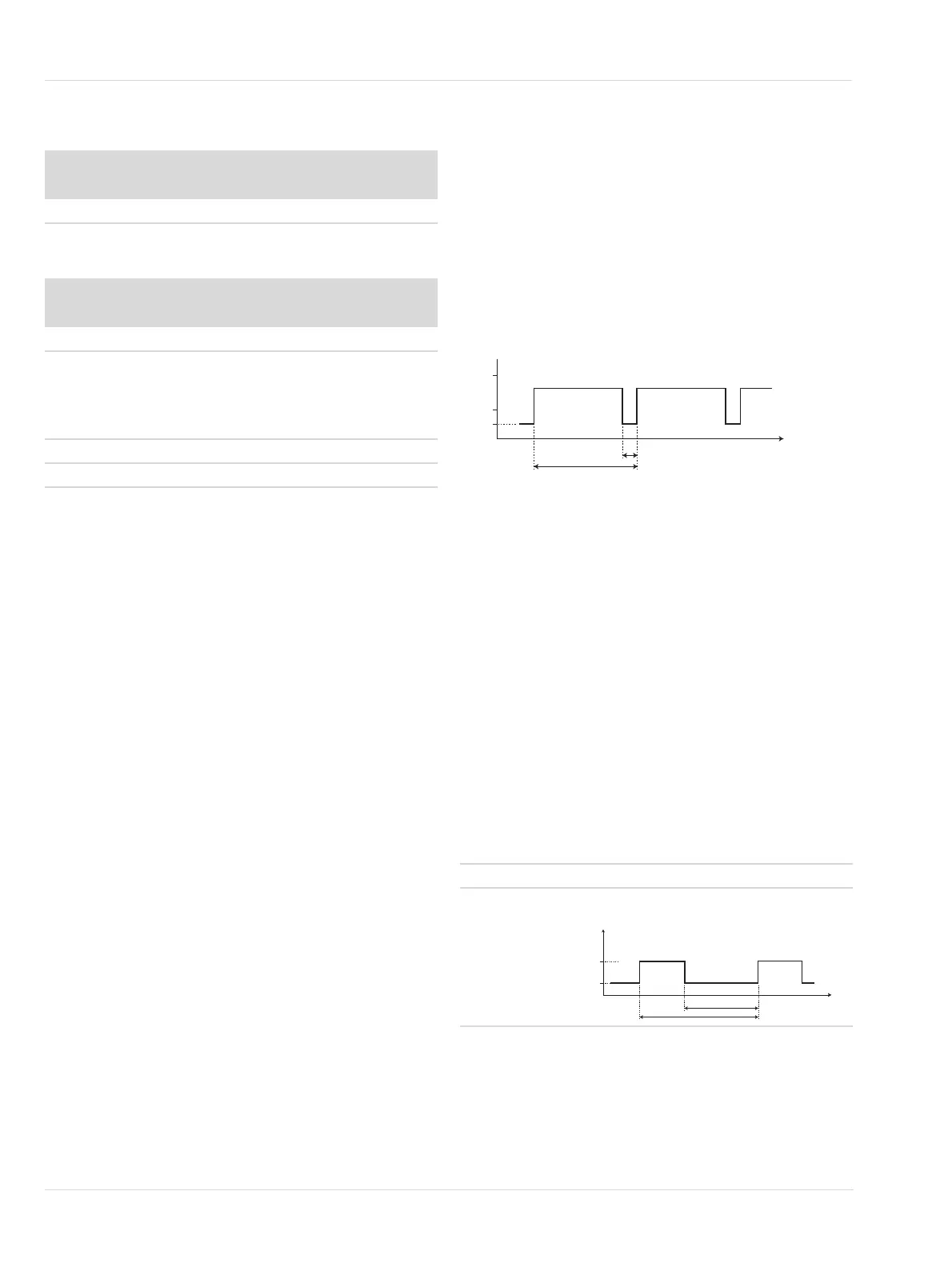

static A constant current that can be configured.

dynamic A square wave signal with the following

characteristics:

t

[s]

T

1

4

20

[mA]

T

2

3

t

[s]

1,1

[mA]

0,7

5

3

Loading...

Loading...