19.3 NP 13 - 4 Electro-pneumatic needle return device

After the trimming of the thread, the machine stops in the 2nd position

when the thread lever has reached its high position. In this position the

needle bar has already left its high position, so that the needle projects

under the raised sewing feet. In order to be able to use the max.

material through-put under the sewing feet for thicker material, the

cylinder turns the needle return device of the hook drive shaft back until

the needle bar has reached the upper dead center. This procedure

occurs immediately after the thread trimming.

Caution Risk of Injury !

Set the hold position and throttle only with the sewing machine

turned off.

Conduct function tests with the sewing machine running only with the

greatest possible caution.

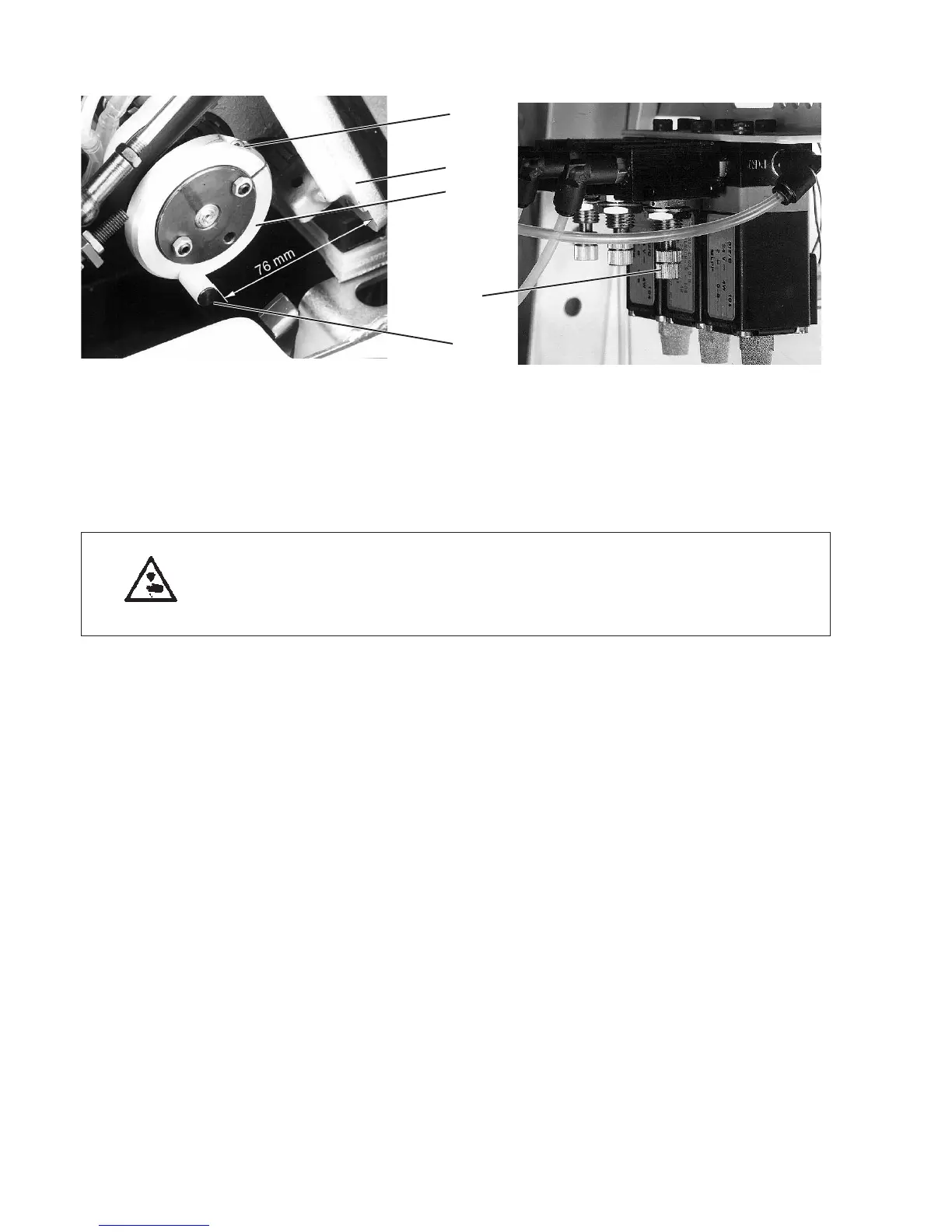

Hold position

The needle bar should be in the high position after the positioning

sequence.

–

Loosen screw 1.

–

Turn ring 3.

In the thread lever high position the clearance between the tappet 5

and the upper edge of the cast boby 2 should be 7 6 mm.

–

Tighten screw 1 again.

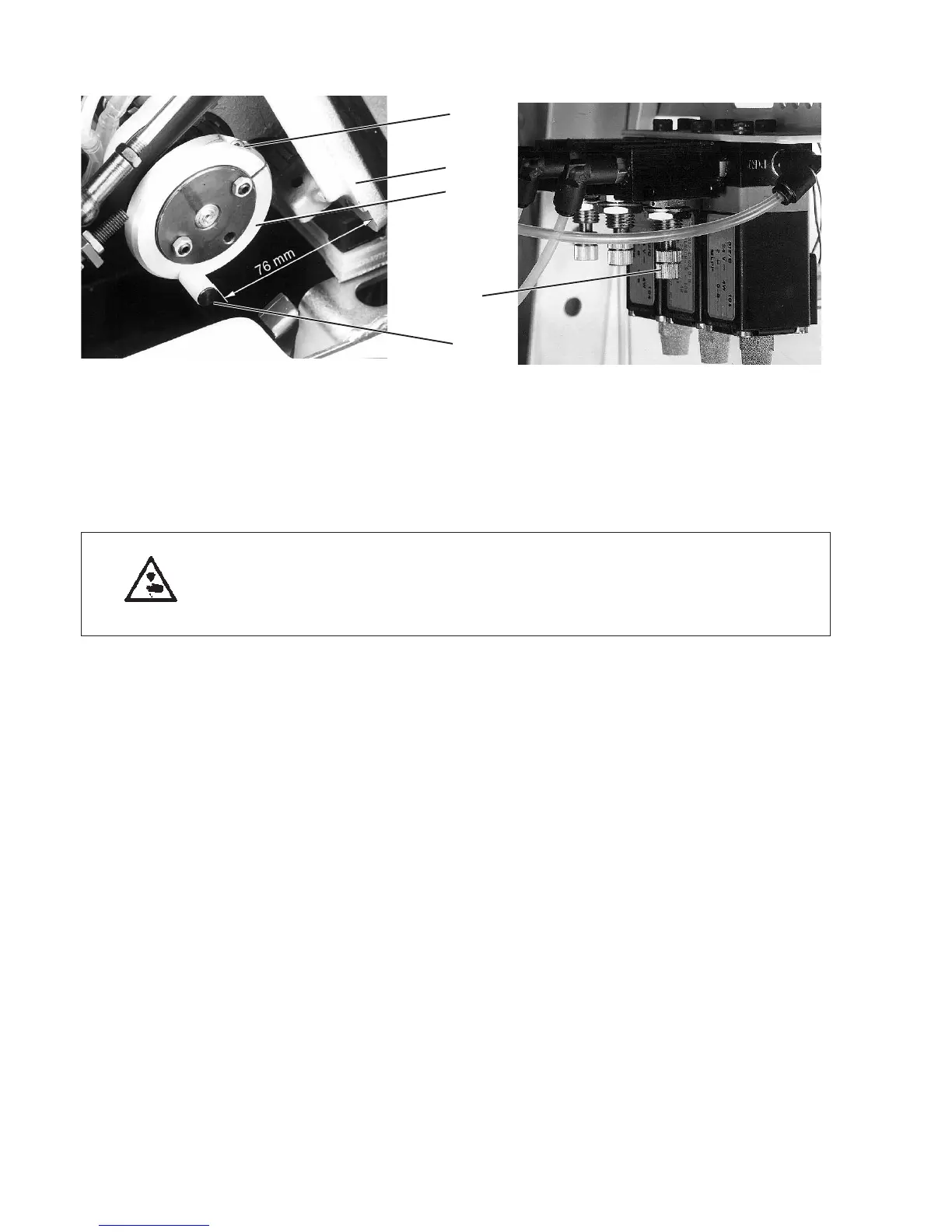

Positioning speed

–

Set throttle 4.

The piston rod should run out the hook drive shaft rapidly and

uniformly.

82

1

2

3

4

5

Loading...

Loading...