12.1 General hints concerning the oil lubrication

Caution: Danger of injury !

Switch off main switch.

All operations on oil lubrication components are to be effected only

when sewing machine is switched off.

Carry out adjusting operations and functional tests of the running

machine only with utmost caution.

–

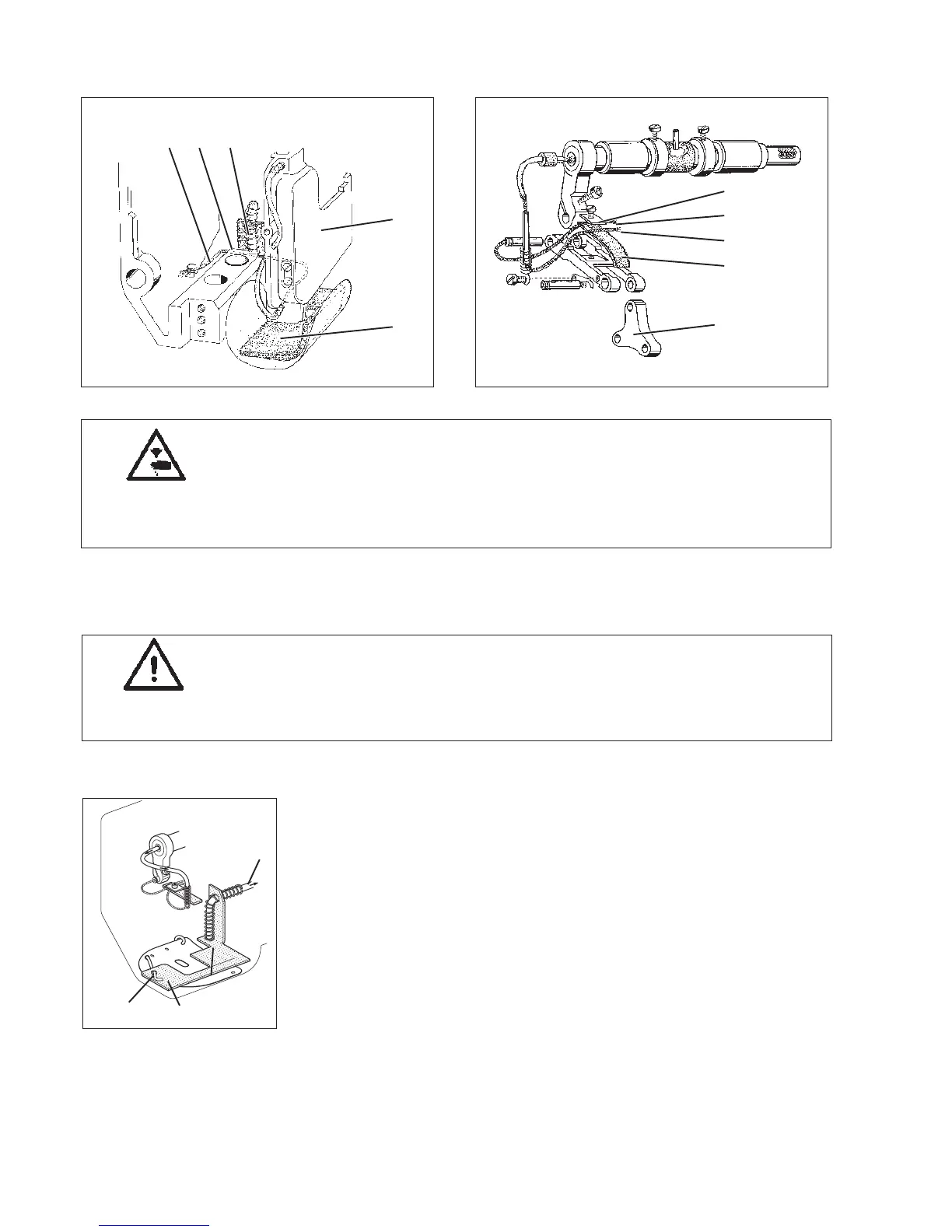

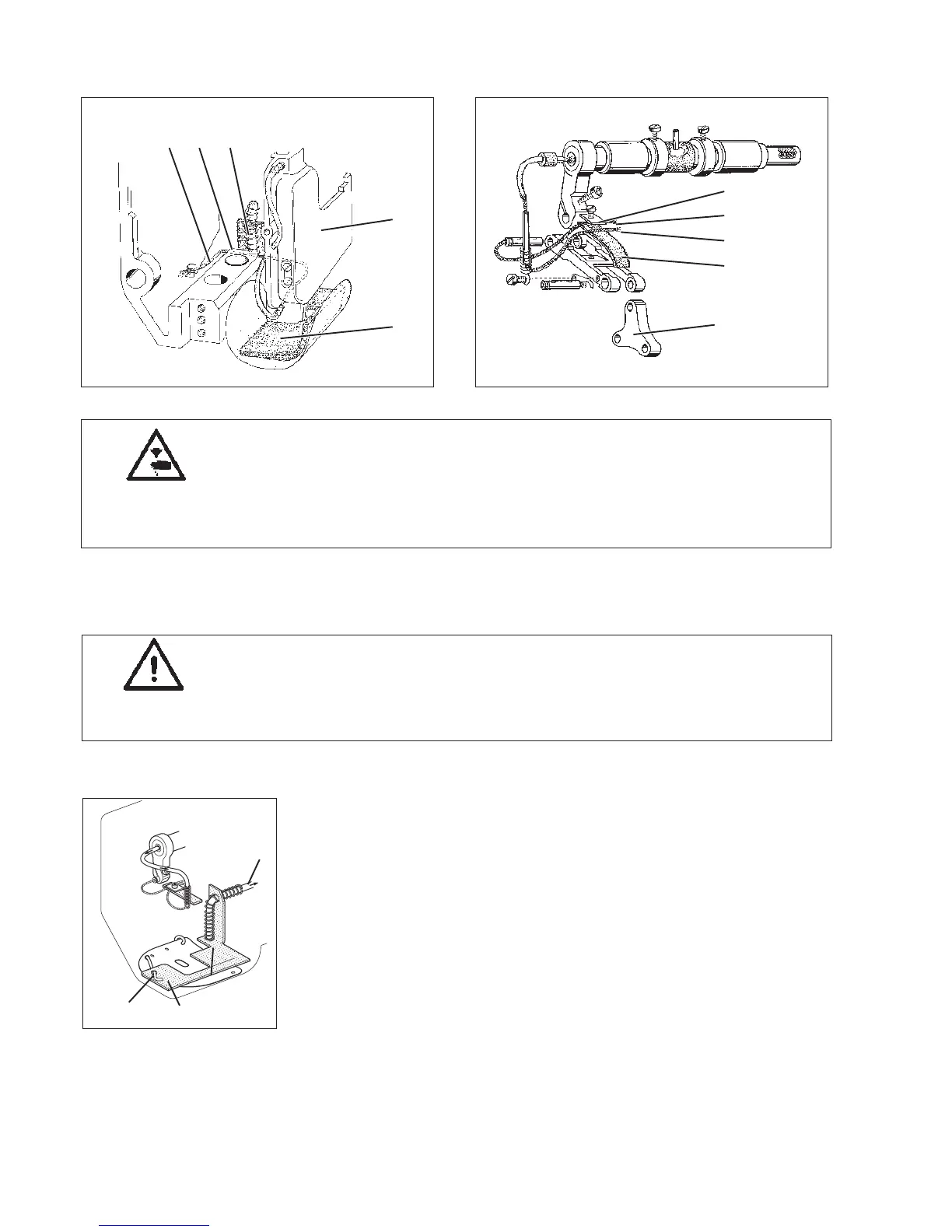

During the break-in period the bolts for the sewing foot lifting

mechanism have to be intensively lubricated via the oil wicks.

ATTENTION!

Before putting the special sewing machine into operation or

after a longer stop the dried out oil wicks and the oil pad 9

in the sewing head have to be soaked with some oil.

See also part 2 (assembly instructions).

–

The oil wicks in the sewing head must not touch the withdrawal

wick 11.

–

The end of withdrawal wick 11 must lie in the oil sump of oil pad 5

over its whole length (approx. 10 - 15 mm). This ensures an

optimum return of the o il from the sewing head.

–

The oil wick 1 leading to the needle bar wing 4 must be fixed

between nut 2 in the cast and support spring 3 of the withdrawal

wick. Oil w ick 1 must not have any contact with oil pad 5.

–

When exchanging the oil pad 9 please observe that the “porous”

side is facing the guide 10.

The two oil wicks 7 and 8 leading to the oil pad 9 must be safely

fixed under sheet 6.

46

12 5

11

6

7

8

9

10

123

4

5

Loading...

Loading...