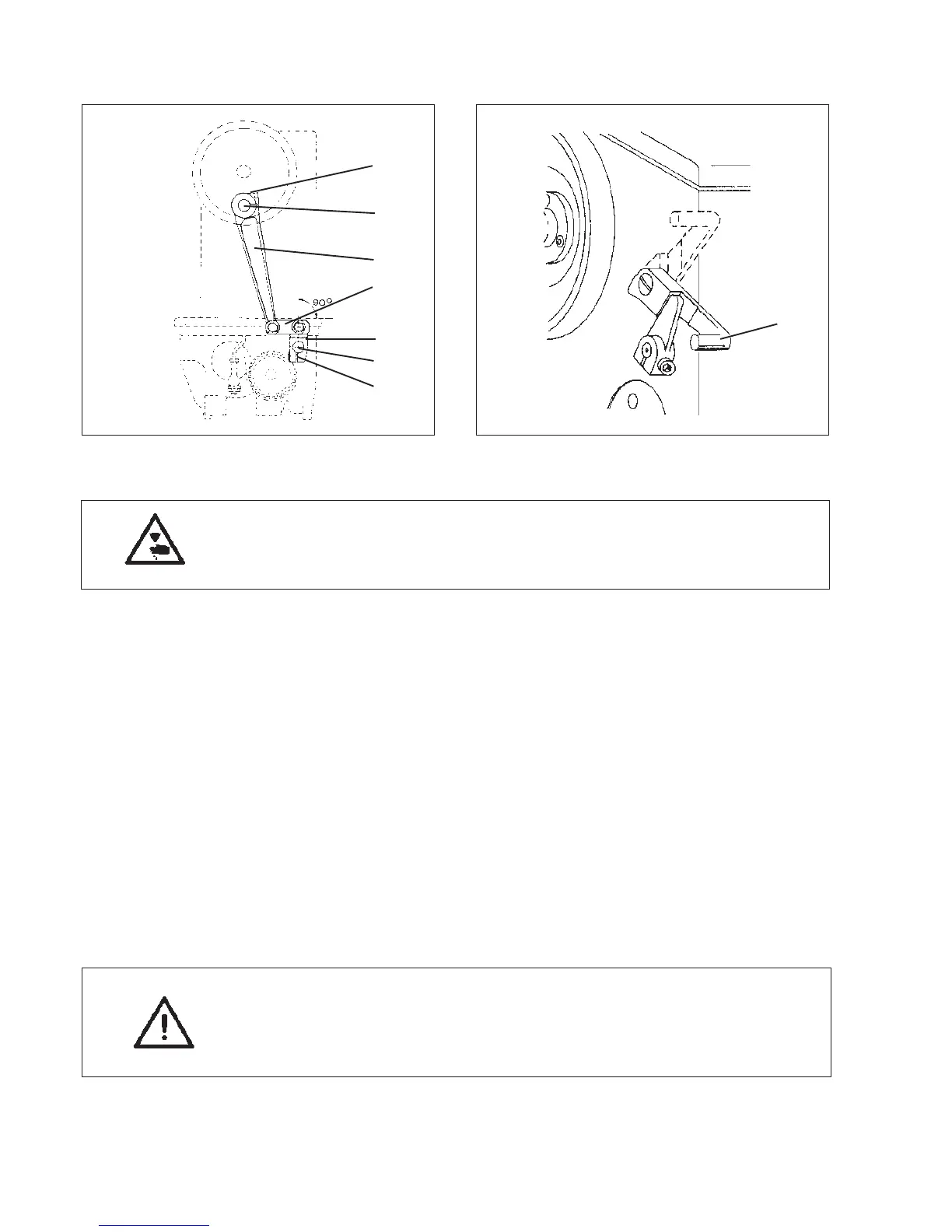

3.2.5 Synchronous run of needle feed and bottom feed

The motion of the feeding shaft 3 is transmitted via block 2 and tie rod 5

to lever 6 and from there via tie rod 3 and lever 2 to needle bar wing 1.

Caution: Danger of injury !

Switch off main switch.

Check and adjust position of block 6 only when sewing machine is

switched off.

Standard checking

During the feed the needle must not move in the needle hole. At stitch

length “0" block 2 must be in perpendicular position.

–

Set stitch length “0”.

–

Check position of block 2.

Block 2 must be in parallel position to the cast edge of the casing.

–

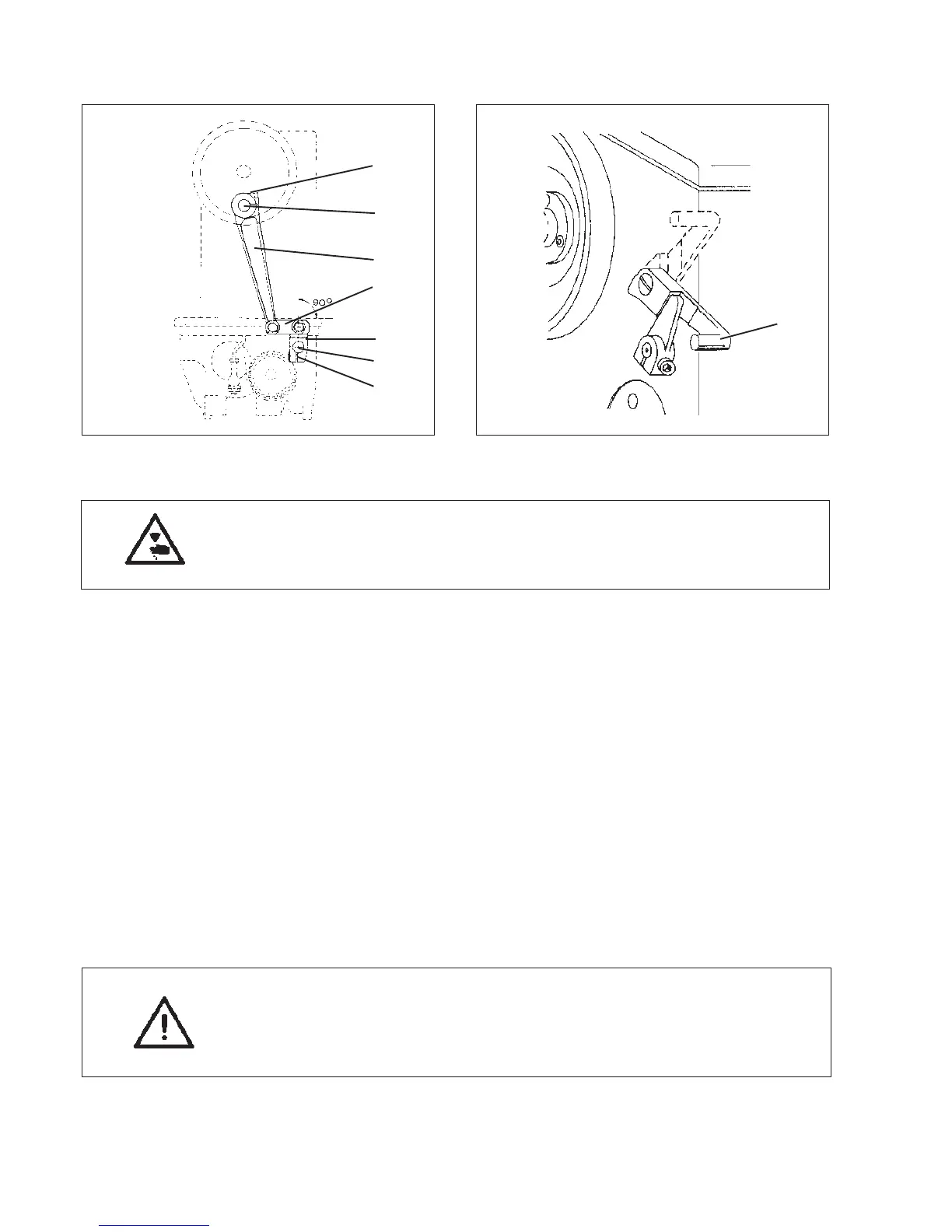

Lock sewing feet in lifted position with lifting lever 8.

–

Set maximum stitch length.

–

Turn handwheel and check the synchronous feeding motion of

feed-dog and needle bar.

The adjustment is correct if the position of the needle in the needle

hole of the feed-dog does not change.

Correction

–

Loosen clamping screws 4 and 7.

–

Twist block 2 on feeding shaft 3.

–

Tighten clamping screws 4 and 7.

ATTENTION !

After twisting of block 2 it has to be checked that the needle

bar wing 1 is positioned in feed direction. Correct, if necessary

(see chapter Position of the needle bar wing in feed direction).

10

7

1

6

5

2

3

4

8

Loading...

Loading...